Modeling and High-Precision Control of a Permanent Magnet Linear Synchronous Motor

Project focus

- Non-linear modeling of permanent magnet linear synchronous motors consisting of curved segments

- Energy-efficient, high-precision position tracking control

- Extension of the control concept to multiple shuttles operating in close proximity

Description

Permanent Magnet Linear Synchronous Motors (PMLSMs) are key technologies in modern industrial automation – particularly in transport and manufacturing systems that demand high performance, precision, and flexibility. Their unique design allows the simultaneous operation of multiple moving units – known as shuttles or movers – on a shared motor, enabling independent and highly dynamic motion control. Thanks to their modular structure with segmented stators, PMLSMs can also be implemented in complex geometries by combining different segment types, such as straight and curved segments. This opens up new design possibilities for innovative manufacturing and transport systems.

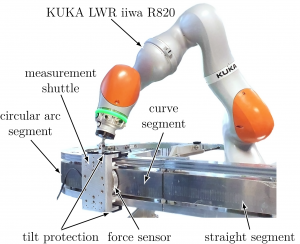

Efficient control of PMLSMs requires an accurate mathematical model. In this project, a magnetic equivalent circuit model (MEC) was developed that can represent arbitrarily curved motor geometries. It offers a combination of high modeling accuracy and computational efficiency. To further enhance model accuracy, a calibration procedure is employed based on measurement data from a custom-built testbench (see Fig. 1).

Test bench for model calibration.

Using the developed model, optimized current patterns are calculated to generate the desired propulsion force on the shuttles. This model-based current optimization makes use of the system’s degrees of freedom to minimize ohmic losses, thereby enabling energy-efficient operation. Motion control is implemented using a two-degree-of-freedom position controller. To further improve control accuracy – especially at segment transitions – an Iterative Learning Control (ILC) method is integrated. This allows effective compensation for manufacturing and assembly tolerances.

Operating multiple shuttles in close proximity introduces additional challenges, such as overlapping current patterns and magnetic interactions between adjacent permanent magnets. As part of this project, a high-precision position control strategy was developed that delivers reliable results even with minimal or varying distances between shuttles.

The developed models and control strategies were successfully validated on a testbench and demonstrated excellent performance. A video showcasing selected results is provided below. Further technical details can be found in the referenced publications.

Video

Selected publications

- G. Fuchs, A. Deutschmann-Olek, A. Kugi, and W. Kemmetmüller, High-precision tracking control of a segmented stator permanent magnet linear synchronous motor, IEEE Transactions on Power Electronics, pp. 1-12, 2025.

[BibTex]@Article{myFuchs2025, author = {Fuchs, G. and Deutschmann-Olek, A. and Kugi, A. and Kemmetm\"uller, W.}, journaltitle = {IEEE Transactions on Power Electronics}, title = {High-precision tracking control of a segmented stator permanent magnet linear synchronous motor}, doi = {10.1109/TPEL.2025.3579258}, pages = {1-12}, journal = {IEEE Transactions on Power Electronics}, year = {2025}, } - G. Fuchs, A. Kugi, and W. Kemmetmüller, Magnetic equivalent circuit modeling of a permanent magnet linear synchronous motor composed of curved segments, Mechatronics, vol. 104, p. 103256, 2024.

[BibTex]@Article{myFuchs2024, author = {Fuchs, G. and Kugi, A. and Kemmetm\"uller, W.}, journaltitle = {Mechatronics}, title = {Magnetic equivalent circuit modeling of a permanent magnet linear synchronous motor composed of curved segments}, doi = {10.1016/j.mechatronics.2024.103256}, issn = {0957-4158}, pages = {103256}, volume = {104}, journal = {Mechatronics}, year = {2024}, } - G. Fuchs, A. Deutschmann-Olek, A. Kugi, and W. Kemmetmüller, Iterative learning-based online calibration of a position sensor system for permanent magnet linear synchronous motors, in Proceedings of the IECON 2024 – 50th Annual Conference of the IEEE Industrial Electronics Society, Chicago, USA, 2024, p. 1–8.

[BibTex]@InProceedings{myFuchs2024a, author = {Fuchs, G. and Deutschmann-Olek, A. and Kugi, A. and Kemmetm\"uller, W.}, booktitle = {Proceedings of the IECON 2024 - 50th Annual Conference of the IEEE Industrial Electronics Society}, title = {Iterative learning-based online calibration of a position sensor system for permanent magnet linear synchronous motors}, doi = {10.1109/IECON55916.2024.10905609}, pages = {1--8}, publisher = {IEEE}, address = {Chicago, USA}, year = {2024}, }

Project partner

Contact

Dipl.-Ing. BSc. Gerd FuchsUniv.Prof. Dr.-Ing. Wolfgang Kemmetmüller