Research laboratories

The Automation and Control Institute is also the home of different research laboratories, which are embedded in the research structure, but constitute specifically set-up and externally funded research units with a fixed term-time.

Christian Doppler Laboratory for Precision Measurements in Motion

The CD Laboratory for Precision Measurements in Motion addresses problems that arise in the precision measurement of moving and vibrating targets. Such measurement setups require detailed understanding of the introduced measurement uncertainties, flexible highly dynamic sensors for precise detection of relative motions, and sophisticated mechatronic designs for motion compensation. Read more →

Christian Doppler Laboratory for Intelligent Process Control for High-Quality Steel Products

The CD-Laboratory for Intelligent Process Control for High-Quality Steel Products conducts problem-oriented fundamental research on the analysis, planning, control, and optimization of typical production processes for high-quality flat steel products and conceptually similar production processes. The research is focused on continous casting, strip coating, and the direct control of material properties. Read more →

Festo System Laboratory for Autonomous Handling Systems

The Festo System Laboratory is devoted to long-run topics of basic research and applied research. With this, ACIN and Festo AG strengthen their successful long-term cooperation in the field of autonomous handling systems. Read more →

Christian Doppler Laboratory for Model-Based Process Control in the Steel Industry

In the CD-Laboratory for Model-Based Process Control in the Steel Industry, control problems from the manufacturing process of steel strip are solved. The research is focussed on hot rolling, annealing, and galvanizing of steel strips. Read more →

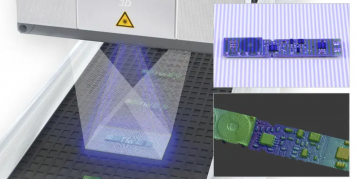

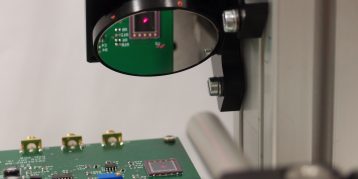

Christian Doppler Laboratory for Precision Engineering for Automated In-Line Metrology

The CD-Laboratory develops 3D metrology system with high resolution, suited to deal with the ever increasing demands on reliability and throughput in modern production systems. High precision and flexibility are thereby required to inspect diverse product features directly in the production line by means of in-line metrology systems. Read more →