Modeling and optimal control of electric machines with redundant stator windings

Project focus

- Modeling of PMSM with redundant stator windings

- Detection of failures of the PMSM

- Optimal fail-safe control of PMSM with redundant stator windings

Description

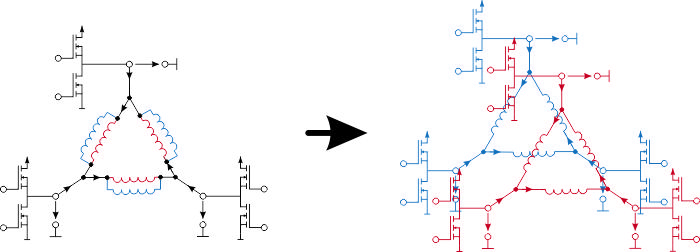

Permanent magnet synchronous machines (PMSM) are used in numerous industrial and automotive applications due to their high power to size ratio. In some of these applications (e.g., electric power steering systems), a fault of the motor (e.g., short circuit of stator windings or open connection of the stator coils), the inverter or the sensors (position or current sensor) can yield an undesired and even potentially dangerous behavior. To allow for an operation of the PMSM even in case of a fault, constructions with redundant stator windings and inverter legs have been proposed in literature, see, e.g. Fig. 1. Although there is a large variety of possible motor constructions, the main idea is to have more than three stator phases which are controlled by independent inverter legs. This allows for an operation, probably with decreased performance, of the PMSM in case of a single fault. Moreover, utilizing a position estimation strategy for PMSMs without a dedicated position sensor gives a fall back solution in case of a position sensor fault.

Setup of the stator windings with a single three-phase and a dual three-phase system

The majority of fail-safe control strategies and sensorless position estimation methods are based on a magnetically linear fundamental wave dq-model of the PMSM. In this research cooperation with Robert Bosch GmbH, strategies for the fault detection, the fail-safe operation and the optimal (position sensorless) control of permanent magnet synchronous machines with redundant stator windings are developed, which are capable to systematically take into account magnetic saturation and non-fundamental wave characteristics of the magnetic field. The basis for the design is a description of the PMSM by magnetic equivalent circuits, which allow to derive models of moderate complexity suitable for the analysis and the controller design. The resulting estimation and control strategies are intended to be utilized in automotive applications, as, e.g., electric power steering systems or electric drive trains.

Project partners

Contact

Univ.Prof. Dr.-Ing. Wolfgang KemmetmüllerUniv.-Prof. Dr.techn. Andreas Kugi