Research area Control of continuous casting processes

Modeling, observer design, and control of continuous casting processes

Research focus

- Physics- and data-based modeling and parameter identification of continuous casting processes

- Soft-sensing techniques for the estimation of non-measurable system quantities

- Modeling and control of fluid flows

- Multivariable control of distributed-parameter systems

At the end of the continuous casting machine, the solidified and still hot strand is cut and stockpiled, © voestalpine Stahl GmbH.

Description

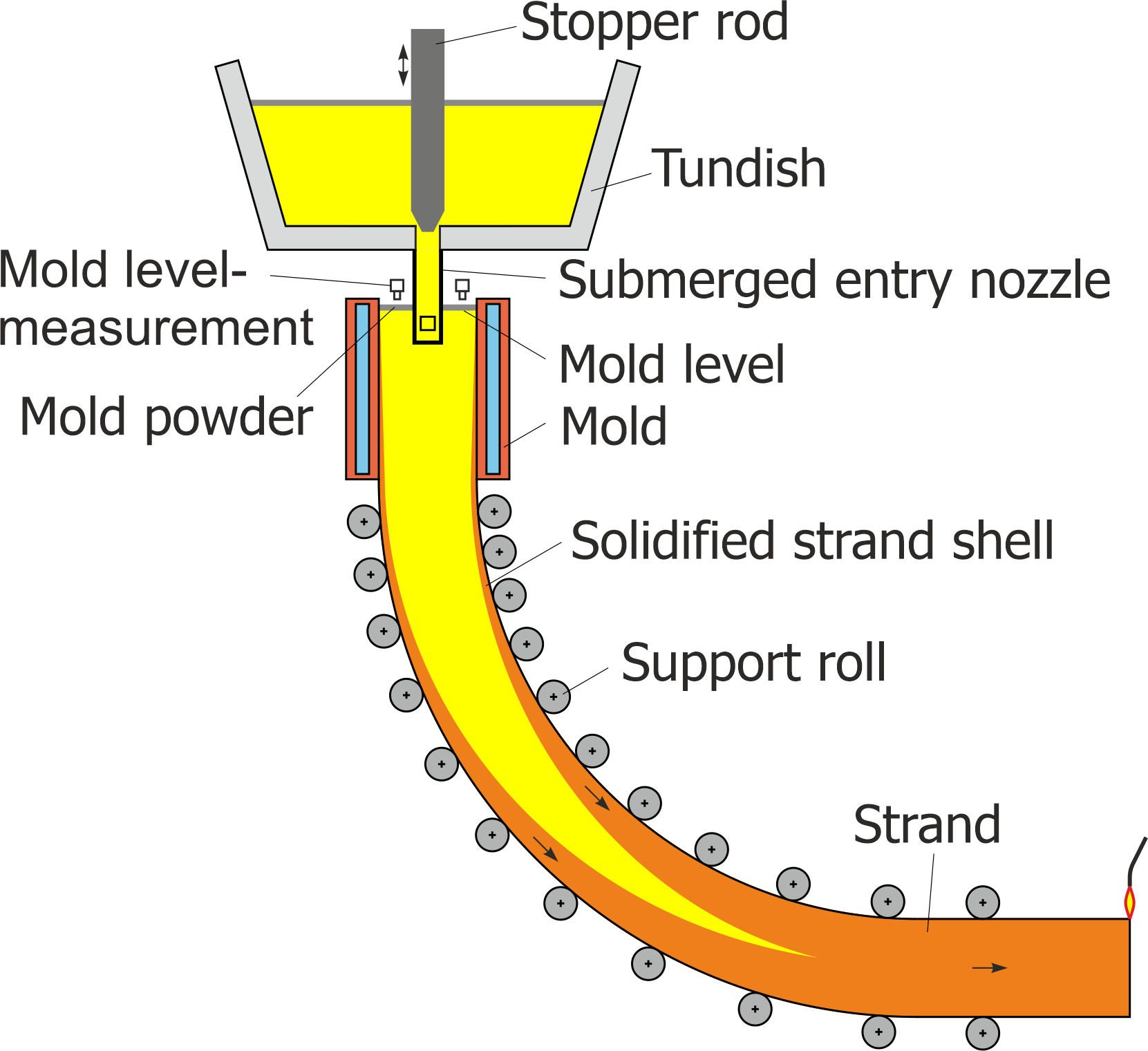

Continuous casting means that molten steel is continuously cast into (endless) strands with a defined profile. The steel flows from the tundish through a stopper valve and a submerged entry nozzle into a water-cooled copper mold (see Fig. 2). The material solidifies from the outer surface of the profile towards the core, i.e., a strand shell forms and its thickness continuously grows inwards. Below the mold, the strand is supported by rolls, which also withdraw it.

Continuous casting machine.

Casting powder is distributed on the surface of the mold level (liquid steel surface). The powder shields the liquid steel from the ambient air and hence avoids oxidation. The powder melts and is also pulled into the gap between strand surface and mold. Here, it reduces the friction and the heat transfer resistance. A constant and planar mold level helps to prevent inclusions of casting powder or voids in the solidified strand. Fluctuations of the mean mold level (planar variations) are caused by disturbances like clogging (solid deposits in the submerged entry nozzle or on the stopper rod), unclogging (sudden detachment of these deposits), and unsteady bulging (unsteady bending of the strand shell between the support rolls).

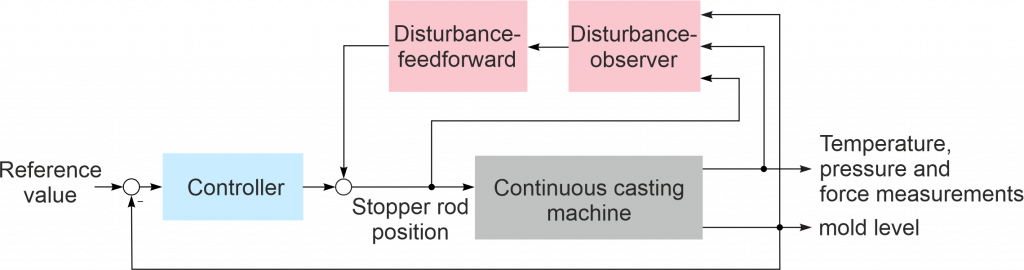

These disturbances of the mold level are compensated by a two-degrees-of-freedom control structure with disturbance feedforward controller (see Fig. 3). The position of the plug serves as control input, which regulates the inflow of steel into the mold. Because the disturbances cannot be directly measured, soft-sensing strategies are used to estimate them based on measurement signals that are available at the plant (see Fig. 3). These soft-sensing methods require models of the disturbance mechanisms, which are also developed in this research project.

Two-degrees-of-freedom control structure (disturbance feedforward and feedback controller).

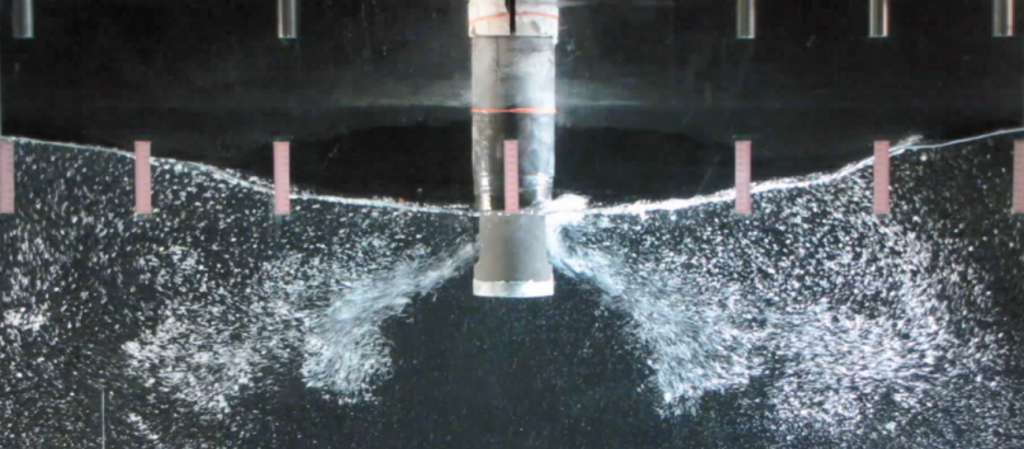

In addition, there may occur non-planar, local variations of the mold level. They are, for instance, caused by unsteady and asymmetric flow patterns in the submerged entry nozzle and in the mold. By adjusting the vertical position of the stopper rod, only the mean flow through the submerged entry nozzle can be influenced. In this context, the potential of new control inputs to influence the fluid flow should be explored. For these research and development activities, a true-to-scale water model of the plant (tundish, stopper valve, submerged entry nozzle, mold) is available. Using optical measurement methods, the water model allows analyses of the control inputs on the flow patterns in the submerged entry nozzle and the mold. Based on measurement data, process models are built, which then facilitate observer and controller designs.

Water model of the submerged entry nozzle and the mold, © voestalpine Stahl GmbH.

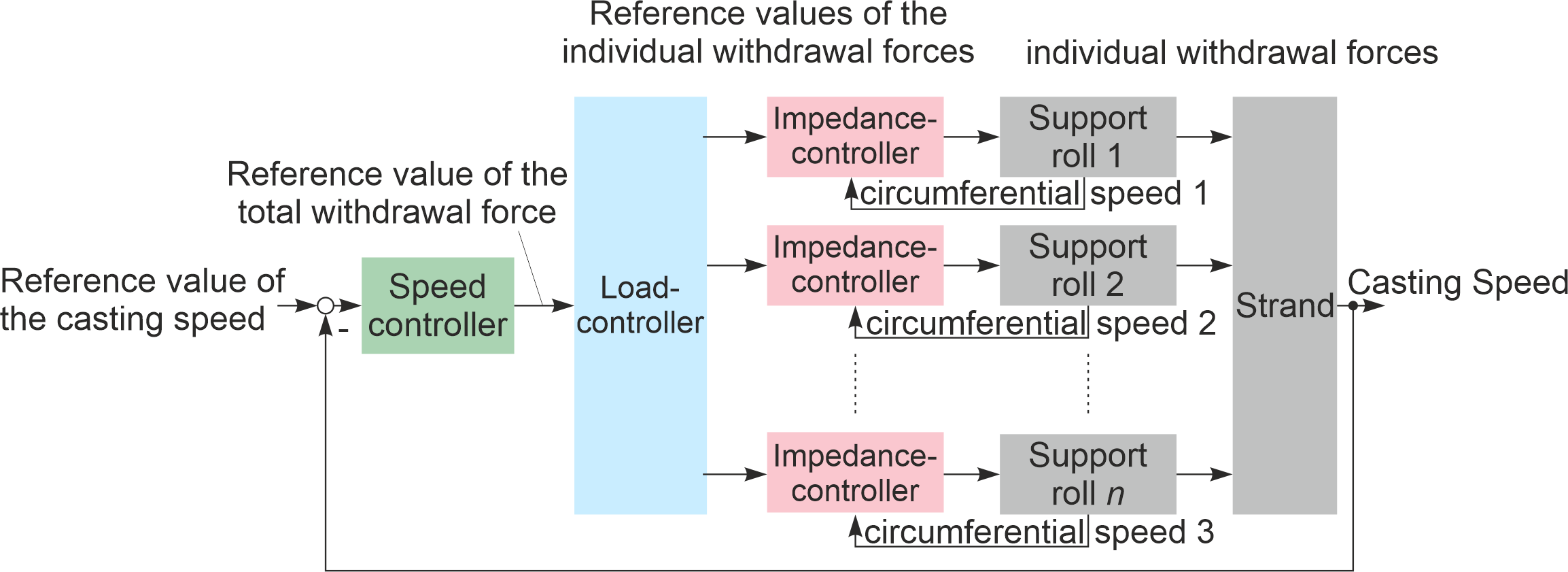

In addition to the mold level and the flow pattern, a uniform and careful withdrawal of the strand (constant strand velocity and uniform distribution of withdrawal forces on driven support rolls) is important for the quality of the cast strand. The friction and slip conditions at the contact points between the rolls and the strand surface are uncertain and may vary considerably. A control strategy for the strand withdrawal process is developed, which satisfies the stated objectives and which should avoid slip of the rolls. For this control problem, a multivariable controller with subordinate impedance controllers may be used, see Fig. 5.

Multivariable controller for strand withdrawal system.

Links

- Sponsors and research partners

- Related projects at the institute