04.08.2025 Quality Control of Injection Molding Machines

Project focus

- Data-driven modeling of part quality considering visual quality inspection

- Repetitive control strategies for stable, high-quality production

- Cycle time optimization under quality and robustness constraints

Description

Injection molding is one of the most widely used manufacturing techniques for producing high volumes of plastic components. Despite its ubiquity, ensuring consistent product quality remains a challenge due to the highly nonlinear dynamics of the process and its sensitivity to environmental conditions and material variability.

Photo of an injection molding machine

This research project, conducted in collaboration with the industrial partner the Center for Vision, Automation & Control, AIT Austrian Institute of Technology GmbH, addresses the need for high-precision, automated quality control in injection molding. The focus lies on developing advanced data-driven methods to achieve consistent product quality and optimal cycle time — two critical factors in modern manufacturing.

This project develops machine learning models to predict part quality to establish the relation physical process data (e.g., cavity pressure) and visual feedback. These models support real-time quality control from cycle to cycle beyond the conventional weight-based criteria. By employing iterative learning control (ILC), the process can adapt to changing conditions across cycles, reducing operator dependency.

In addition, the project investigates cycle time optimization under quality constraints, ensuring efficiency without compromising robustness. The combination of data-driven modeling and repetitive control enables a more reliable and autonomous injection molding process.

This project contributes to the transition from operator-dependent process tuning to automated, intelligent quality control in injection molding. By combining machine learning and control theory, we enable robust, fast, and reliable production even under variable ambient and material conditions.

Project partners

27.05.2025 Modeling and High-Precision Control of a Permanent Magnet Linear Synchronous Motor

Project focus

- Non-linear modeling of permanent magnet linear synchronous motors consisting of curved segments

- Energy-efficient, high-precision position tracking control

- Extension of the control concept to multiple shuttles operating in close proximity

Description

Permanent Magnet Linear Synchronous Motors (PMLSMs) are key technologies in modern industrial automation – particularly in transport and manufacturing systems that demand high performance, precision, and flexibility. Their unique design allows the simultaneous operation of multiple moving units – known as shuttles or movers – on a shared motor, enabling independent and highly dynamic motion control. Thanks to their modular structure with segmented stators, PMLSMs can also be implemented in complex geometries by combining different segment types, such as straight and curved segments. This opens up new design possibilities for innovative manufacturing and transport systems.

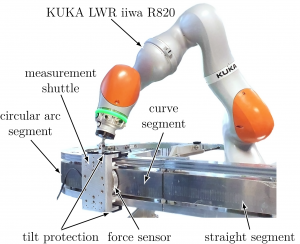

Efficient control of PMLSMs requires an accurate mathematical model. In this project, a magnetic equivalent circuit model (MEC) was developed that can represent arbitrarily curved motor geometries. It offers a combination of high modeling accuracy and computational efficiency. To further enhance model accuracy, a calibration procedure is employed based on measurement data from a custom-built testbench (see Fig. 1).

Test bench for model calibration.

Using the developed model, optimized current patterns are calculated to generate the desired propulsion force on the shuttles. This model-based current optimization makes use of the system’s degrees of freedom to minimize ohmic losses, thereby enabling energy-efficient operation. Motion control is implemented using a two-degree-of-freedom position controller. To further improve control accuracy – especially at segment transitions – an Iterative Learning Control (ILC) method is integrated. This allows effective compensation for manufacturing and assembly tolerances.

Operating multiple shuttles in close proximity introduces additional challenges, such as overlapping current patterns and magnetic interactions between adjacent permanent magnets. As part of this project, a high-precision position control strategy was developed that delivers reliable results even with minimal or varying distances between shuttles.

The developed models and control strategies were successfully validated on a testbench and demonstrated excellent performance. A video showcasing selected results is provided below. Further technical details can be found in the referenced publications.

Video

Selected publications

- G. Fuchs, A. Deutschmann-Olek, A. Kugi, and W. Kemmetmüller, High-precision tracking control of a segmented stator permanent magnet linear synchronous motor, IEEE Transactions on Power Electronics, pp. 1-12, 2025.

[BibTex]@Article{myFuchs2025, author = {Fuchs, G. and Deutschmann-Olek, A. and Kugi, A. and Kemmetm\"uller, W.}, journaltitle = {IEEE Transactions on Power Electronics}, title = {High-precision tracking control of a segmented stator permanent magnet linear synchronous motor}, doi = {10.1109/TPEL.2025.3579258}, pages = {1-12}, journal = {IEEE Transactions on Power Electronics}, year = {2025}, } - G. Fuchs, A. Kugi, and W. Kemmetmüller, Magnetic equivalent circuit modeling of a permanent magnet linear synchronous motor composed of curved segments, Mechatronics, vol. 104, p. 103256, 2024.

[BibTex]@Article{myFuchs2024, author = {Fuchs, G. and Kugi, A. and Kemmetm\"uller, W.}, journaltitle = {Mechatronics}, title = {Magnetic equivalent circuit modeling of a permanent magnet linear synchronous motor composed of curved segments}, doi = {10.1016/j.mechatronics.2024.103256}, issn = {0957-4158}, pages = {103256}, volume = {104}, journal = {Mechatronics}, year = {2024}, } - G. Fuchs, A. Deutschmann-Olek, A. Kugi, and W. Kemmetmüller, Iterative learning-based online calibration of a position sensor system for permanent magnet linear synchronous motors, in Proceedings of the IECON 2024 – 50th Annual Conference of the IEEE Industrial Electronics Society, Chicago, USA, 2024, p. 1–8.

[BibTex]@InProceedings{myFuchs2024a, author = {Fuchs, G. and Deutschmann-Olek, A. and Kugi, A. and Kemmetm\"uller, W.}, booktitle = {Proceedings of the IECON 2024 - 50th Annual Conference of the IEEE Industrial Electronics Society}, title = {Iterative learning-based online calibration of a position sensor system for permanent magnet linear synchronous motors}, doi = {10.1109/IECON55916.2024.10905609}, pages = {1--8}, publisher = {IEEE}, address = {Chicago, USA}, year = {2024}, }

Project partner

B&R Industrial Automation GmbH

16.02.2025 LunarAssembly

Large Time-Delay Teleoperation for Enabling Robotic Assembly on the Moon through Extended Reality and Machine Learning

Recent scientific discoveries about the presence of water-ice on moon have led to an increased interest in lunar space missions. For the construction and maintenance of future lunar bases, robotic technologies will become crucial. Teleoperation of robotic systems is an established technology that allows an operator to control a remote robot from a dislocated operator station. The level of emersion of the operator in the remote scene can be significantly increased by the use of haptic feedback. However, for ground-based teleoperation of a lunar robot, significant time delays in the order of several seconds occur, which prevent nowadays teleoperation technology to be applied in such scenarios. While effective control frameworks are available to handle delays up to ~1s, the performance of these algorithms drastically degrades when the delay increases.

The LunarAssembly project treats a fundamental scientific challenge, namely the teleoperation of robotic systems under large time delays, motivated by a scenario of remote assembly on the Moon. We believe that such high delays require novel paradigms for teleoperation with an appropriate interplay between autonomous functions and human intervention. We will develop fundamental extensions of the time-domain passivity framework with the aim of improving transparency under high time delay. These novel control algorithms are combined with a curriculum-based framework for incremental learning of autonomous skills, leveraging recent progress in ML for robotics. All this will be enabled by XR technologies based on 3D reconstruction of the remote environment. Besides the progress in these individual research fields, we believe that an innovation also lies in the appropriate interplay of these technologies.

Project partners:

- ACIN Robotic Systems Lab (TU Wien)

- ICT Autonomous Systems Lab (TU Wien)

- Space Robotics Research Group, SnT, University of Luxembourg

Funding Organization:

Austrian Science Fund (FWF)

08.01.2025 Caring Robots // Robotic Care

Our aim is to re-imagine robotic technology in care by developing technology that is useful, safe, meaningful, and wanted, through a design process that involves caregivers, people in care, care organizations, and other stakeholders. The project Caring Robots // Robotic Care is a transdisciplinary research collaboration by TU Wien, IT:U Interdisciplinary Transformation University Austria, Caritas Wien, and Technisches Museum Wien.

The development of robots for use in care is a much-discussed scenario that is strongly polarized. On the one hand, there is the hope that (robotic) technology will help us meet the challenges of demographic change, support caregivers, and help people lead self-determined lives. On the other hand, there are fears that robots will replace human care and push people in need of care into social marginalization. The goal of this project is to explore possible and desirable roles of robots or similar technologies in the complex context of care. We aim to bring a wide range of actors – caregivers, clients, interest groups, users, and political decision-makers – together with experts from robotics, computer science, and sociology, to collectively ask the question how technology can and should (or should not) change the future of care.

08.01.2025 MANiBOT

MANiBOT aims to empower bi-manual, mobile, service robots with superior physical capabilities able to perform a wide variety of manipulation tasks, with highly diverse objects, in a human-like manner and performance, in diverse, challenging environments.

The project seeks to revolutionise the robotics landscape by enhancing robot’s handling skills, including simple grasping, pick-and-place operations, bi-manual and non-prehensile manipulation, and ensuring adaptive responses to changing environments or to the properties of objects.

To achieve these capabilities, innovations will be developed in the fields of advanced environment understanding, efficient manipulation techniques, robot cognitive functions and physical intelligence. The researchers will implement their solutions with a focus on baggage handling and supermarket shelves’ restocking, with piloting of robots in relevant environments.

Partners:

Centre for Research and Technology Hellas

Fraport Greece

TWI Hellas

University of Bristol

BioRobotics Institute of Sant’Anna School of Advanced Studies

Central Institute for Labour Protection – National Research Institute (CIOP-PIB)

Diamantis Masoutis SA

Asea Brown Boveri SA (ABB)

Aristotle University of Thessaloniki

The Technical University of Darmstadt

Schwarz Digits

The University of Burgos (UBU)

08.01.2025 TraceBot

Today manual procedures still dominate when it comes to creating and testing new healthcare products. This is because regulations require certainty in the execution of each process step and systematic checking to verify task completion, known as traceability. A particular challenge in this field is the handling of sterile medical products. Lab automation with dexterous and reasoning robots is the solution.

The EU funded TraceBot project aims at addressing healthcare-related processes, and more exactly the membrane-based sterility testing process. The objective of TraceBot is to bring verifiable actions to robot manipulation by reasoning over sensor-actor trails in a traceability framework based on digital-twin technology and extend current robot motion planners with the automatic execution of self-checking procedures that create a semantic trace of the actions performed. The goal is to create robotic systems able to understand what they perceive and do, to ensure that any manipulation action is verified, thus meeting the needs of the regulated environment.

The TraceBot project brings together six strong partners from five countries: Astech Projects Limited (England), Commissariat à l‘Energie Atomique et aux Energies Alternatives (France), Fundación Tecnalia Research & Innovation (Spain), Invite GmbH (Germany), Technische Universität Wien (Austria) and Universität Bremen (Germany) and is being guided by representatives of the pharmaceutical industry. Each partner contributes its own expertise by providing a solution working hand-in-hand with each other partner’s solution. This cooperation will permit the development of tactile grippers for handling medical products, the design of a set of manipulation skills to execute the regulatory checking actions for every assembly step, the generation of an intuitive programming method for a quick adaptation to novel products and tasks and, last but not least, the development of a reasoning framework to monitor and control the safe and failure-resistant operation of the robot system, in order to meet the need of safety-critical automation. The TraceBot project’s coordination, communication and dissemination is carried out by the health network BioLAGO (Germany).

08.01.2025 iChores

iChores is a project with the scientific goal of creating collaborative human‑robot interfaces for intuitive interaction through multiple modalities.

Our research focuses on investigating the methods that enable a collaborative robot to extract task‑relevant information from the gaze and gestures of a human partner, and how gaze, gesture, and speech information can be combined for a more natural and intuitive interface. We employ a user‑centered design methodology and explore research questions and hypotheses regarding the impact of combining modalities on the robot’s understanding, error count, task duration, user experience, comfort, and trust.

Partners:

Czech Technical University in Prague, Czech Institute of Informatics Robotics and Cybernetics

Jagiellonian University in Cracow, Institute of Philisophy

09.10.2024 SpecTrackular

Project goals

- Development of a telescope system for spectroscopy analysis of space debris

- Self-learning pointing model

- Improved telescope tracking via orbital data measurement

Description

More satellites have been launched in the year 2023 than any year prior. 40% of all objects currently tracked within earth’s orbit have been sent there in the last four years. An unwanted side effect of this trend is a steady increase in the amount of space debris orbiting earth. Should the trend set in previous years continue, space debris will become an ever increasing threat to satellites. Until there is a global plan to prevent future as well as remove current space debris, an improvement in orbit prediction accuracy is vital. Thereby, unlikely collisions can be detected and the lifetime of satellites extended.

ACINOGS: Optical ground station

SpecTrackular aims to develop a telescope system capable of measuring the orbital path of space debris and allow spectroscopic characterization. Therefore, high-precision pointing and tracking of the telescope system, an improvement of the orbital path based on collected data and a spectroscopic measurement of the debris object are needed. Reflectance spectroscopy requires particularly precise tracking, because the light source, aperture and detector need to be aligned within a few arcseconds.

In order to achieve the required tracking accuracy, a self-learning pointing model will be developed, which can adapt to any emerging misalignment. Using the updated telescope system, the discrepancy between publicly available orbital data and the actual orbit can be measured and integrated into future predictions. The combination of the presented advancements will hopefully lead to a telescope system capable of tracking space debris for minutes at a time, with a tracking accuracy of less than <2” and, thereby, enable spectroscopic measurements. A spectroscopic analysis of the incoming light can give information on the material, pose and rotation of the debris object, which can, in turn, lead to further improvement of the orbit prediction accuracy.

Use case

- Space debris surveillance

Project partners

- ASA Astrosysteme GmbH

Funding

- FFG – Research Promotion Agency, Austrian Space Applications Programme (ASAP)

09.08.2024 Development of the AI-based autonomous task planning and robot teaching solution for highly complex manufacturing assembly process

The project aims to develop complex manipulation skills with dual arm manipulaltors for industrial manufacturing and assembly processes.

Partners

- KIMM (coordinator)

- KITECH

- KAERI

- KETI

- KIRO

- KAIST

- Lline

- TU Wien

Funding

South Korean Ministry of Trade, Industry, and Energy (MOTIE)

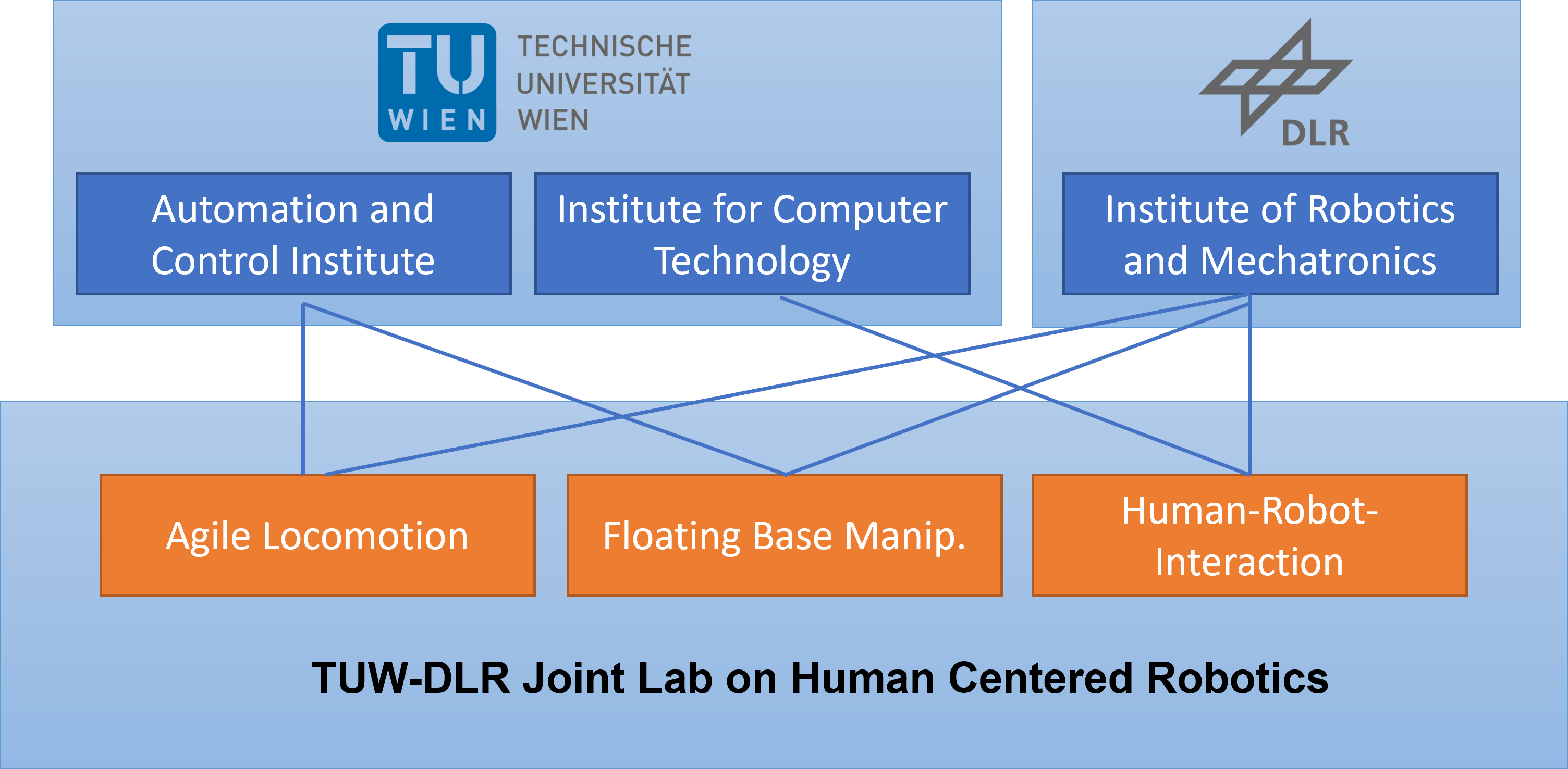

09.08.2024 TUW/DLR Joint Laboratory on Human Centered Robotics

The TUW-DLR Joint Laboratory on Human Centered Robotics is a virtual Competence Center between TU Wien and the German Aerospace Center (DLR). The mission of the Joint Laboratory is to conduct internationally leading research in the area of Human Centered Robotics with a particular focus on real-time control and machine learning in human-robot interaction. The current activities in the joint lab are clustered in three main topic areas:

- Agile Legged Locomotion

- Dexterous Whole-Body-Control for Floating Base Manipulators

- Human-Robot-Interaction

Participants:

- Robotic Systems Lab at Automation and Control Institute (ACIN), TU Wien

- Autonomous Systems Lab at Institute for Computer Technology (ICT), TU Wien

- Institute of Robotics and Mechatronics (RM) at German Aerospace Center (DLR e.V.)