Christian Doppler Laboratory for Precision Engineering for Automated In-Line Metrology

Head of the laboratory: Univ.-Prof. Dipl.-Ing. Dr.sc.techn. Georg Schitter

Start: September, 1st 2015

The CD-Laboratory develops 3D metrology system with high resolution, suited to deal with the ever increasing demands on reliability and throughput in modern production systems. High precision and flexibility are thereby required to inspect diverse product features directly in the production line by means of in-line metrology systems. There is an increasing demand for high precision metrology systems which are versatile and adaptable to the actual application. The workpieces are thereby getting more and more complex and include for example freeform surfaces, additive manufacturing and a high spatial resolution, which already reaches into the nanometer domain.

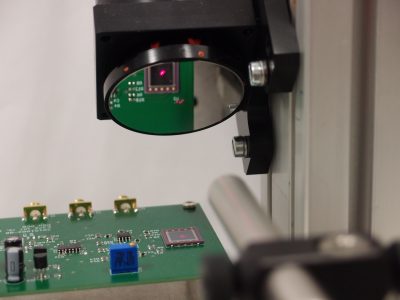

By integration of optical point- and line-sensors with high precision motion systems and state-of-the-art signal processing, 3D metrology systems with highest resolution and measurement speed are developed in the CD-laboratory. In the course of fundamental research new methods for system design and integration of high precision mechatronic systems are developed, to design for example high performance mechatronic systems for scan-based metrology systems. An integrated approach allows to optimize the interaction of the mechatronic metrology and positioning system and the real-time control system from the very beginning of the design phase, by systematically considering all components of the system and the requirements of the target application. Additionally the research in the CD-laboratory focuses on the development of methods for flexible and areal acquisition of metrology data, and efficient algorithms for automated evaluation of this data. These methods eventually are the basis for automated metrology directly in the production line, for dimensional metrology, for color measurements and the characterization of optical components.

Results of the research in the CD-Laboratory will be flexible and versatile systems for non-tactile 3D-metrology, which for example will be applicable in roboter-based metrology applications in the production line to inspect the product quality with high resolution and high throughput and to monitor production systems.

Employees of MICRO-EPSILON MESSTECHNIK GmbH & Co. KG, ATENSOR Engineering and Technology Systems GmbH and the researchers of ACIN form the team of the CD-laboratory for Precision Engineering for Automated In-Line Metrology.