28.06.2017 Nichtlineare Regelungs- und Schutzkonzepte für Smart Power ICs

Projektschwerpunkte

- Mathematische Modellierung und Systemanalyse eines Smart Power ICs

- Entwicklung von modellbasierten, digitalen Regelungs- und Schutzfunktionen

- Umsetzung und Verifikation am Versuchsaufbau

Beschreibung

Smart Power ICs werden für das Schalten von Mittel- und Hochstromlasten in automobilen und industriellen Anwendungen eingesetzt. Bild 1 zeigt dazu exemplarisch das Anwendungsgebiet der PROFET™ Smart Power IC Serie von Infineon.

Einsatzgebiet der Infineon PROFET™ Serie. © Infineon Technologies AG.

Smart Power ICs kombinieren Leistungsschalter mit Regelungs- und Schutzfunktionen in einer integrierten Schaltung. Aktuell werden diese Regelungs- und Schutzfunktionen noch größtenteils mit analogen Schaltungen realisiert. Diese analog integrierten Regelungs- und Schutzfunktionen sind erprobt, robust und zuverlässig. Ein großer Nachteil dieser analogen Funktionen ist jedoch unter anderem die geringe Wiederverwendbarkeit des Schaltungsdesigns für unterschiedliche Leistungsklassen und verschiedene Lastfälle. Zudem sind leistungsfähige Regelungs- und Lastschätzalgorithmen nur bedingt mit analogen Schaltungen implementierbar.

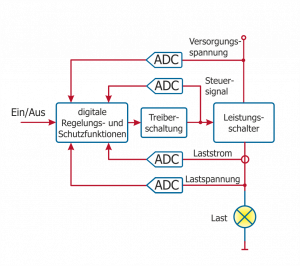

Leistungsfähige System on a Chip Lösungen (SoC) ermöglichen es diese Nachteile durch eine digitale Implementierung der Regelungs- und Schutzfunktionen zu umgehen. Dazu werden die charakteristischen Größen des Leistungsschalters gemessen, diskretisiert und im Digitalrechner des SoC weiterverarbeitet. Angesteuert wird der Leistungsschalter mithilfe einer digital steuerbaren Treiberschaltung. Das Grundprinzip eines solchen digitalen Smart Power ICs ist in Abbildung 2 dargestellt.

Grundprinzip eines digitalen Smart Power ICs.

In diesem Projekt wird die Entwicklung von modellbasierten, digitalen Regelungs- und Schutzfunktionen für Smart Power ICs behandelt. Dazu gehören unter anderem die Entwicklung von Optimalsteuerungsstrategien zur Reduzierung der beim Schaltvorgang auftretenden elektromagnetischen Emissionen und die Entwicklung von Lastschätzstrategien.

Ausgewählte Veröffentlichungen

- M. Blank, T. Glück, H-P. Kreuter, and A. Kugi, Adaptive Gatestromprofile für die Schaltflankenregelung von Smart Power ICs zur EMI Reduzierung, in Tagungsband EMV-Fachtagung, Graz, Austria, 2015.

[BibTex]@InProceedings{Blank15, author = {Blank, M. and Gl\"uck, T. and Kreuter, H-P. and Kugi, A.}, title = {{A}daptive {G}atestromprofile f{\"u}r die {S}chaltflankenregelung von {S}mart {P}ower {ICs} zur {EMI} {R}eduzierung}, booktitle = {Tagungsband EMV-Fachtagung}, year = {2015}, volume = {79}, series = {OVE}, publisher = {TU Graz}, month = {4}, isbn = {978-3-85133-085-4}, address = {Graz, Austria}, } - M. Blank, T. Glück, A. Kugi, and H-P. Kreuter, Digital slew rate and S-shape control for Smart Power Switches to reduce EMI generation, IEEE Transactions on Power Electronics, vol. 30, iss. 9, p. 5170–5180, 2015.

[BibTex] [Download]@Article{Blank14b, Title = {Digital slew rate and {S-shape} control for Smart Power Switches to reduce {EMI} generation}, Author = {Blank, M. and Gl\"uck, T. and Kugi, A. and Kreuter, H-P.}, Journal = {IEEE Transactions on Power Electronics}, Pages = {5170--5180}, Volume = {30}, Year = {2015}, Number = {9}, Doi = {10.1109/TPEL.2014.2361021}, } - M. Blank, T. Glück, A. Kugi, and H-P. Kreuter, EMI Reduction for Smart Power Switches by Iterative Tracking of a Gaussian-shape Switching Transition, in Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management (PCIM), Nuremberg, Germany, 2015, p. 1361–1368.

[BibTex] [Download]@InProceedings{Blank15a, author = {Blank, M. and Gl\"uck, T. and Kugi, A. and Kreuter, H-P.}, title = {{EMI} Reduction for Smart Power Switches by Iterative Tracking of a Gaussian-shape Switching Transition}, booktitle = {Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management (PCIM)}, year = {2015}, publisher = {VDE VERLAG GMBH, Berlin}, month = {5}, isbn = {978-3-8007-3924-0}, pages = {1361--1368}, url = {http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=7149176}, address = {Nuremberg, Germany}, } - M. Blank, T. Glück, A. Kugi, and H-P. Kreuter, Power Optimal Gate Current Profiles for the Slew Rate Control of Smart Power ICs, in Proceedings of the 19th IFAC World Congress, Cape Town, South Africa, 2014, p. 7190 – 7195.

[BibTex]@InProceedings{Blank14a, author = {Blank, M. and Gl\"uck, T. and Kugi, A. and Kreuter, H-P.}, title = {Power Optimal Gate Current Profiles for the Slew Rate Control of Smart Power ICs}, booktitle = {Proceedings of the 19th IFAC World Congress}, year = {2014}, month = {8}, pages = {7190 -- 7195}, doi = {10.3182/20140824-6-ZA-1003.00124}, address = {Cape Town, South Africa}, } - M. Blank, T. Glück, A. Kugi, and H. P. Kreuter, Modellierung eines Smart High-Side Power ICs, at – Automatisierungstechnik, vol. 61, iss. 12, p. 849–858, 2013.

[BibTex] [Download]@Article{Blank13, Title = {{Modellierung eines Smart High-Side Power {IC}s}}, Author = {M. Blank and T. Gl{\"u}ck and A. Kugi and H.P. Kreuter}, Journal = {at -- Automatisierungstechnik}, Pages = {849--858}, Volume = {61}, Year = {2013}, Number = {12}, Doi = {10.1515/auto.2013.1003}, } - M. Blank, T. Glück, H-P. Kreuter, and A. Kugi, Modellierung eines Smart High-Side Power ICs, in Tagungsband GMA-Fachausschuss 1.30 “Modellbildung, Identifikation und Simulation in der Automatisierungstechnik“, Anif/Salzburg, Austria, 2012, p. 49–65.

[BibTex]@InProceedings{Blank12, author = {Blank, Mathias and Gl{\"u}ck, Tobias and Kreuter, H-P. and Kugi, Andreas}, title = {{Modellierung eines Smart High-Side Power {IC}s}}, booktitle = {Tagungsband GMA-Fachausschuss 1.30 ''Modellbildung, Identifikation und Simulation in der Automatisierungstechnik''}, year = {2012}, publisher = {Technische Universit{\"a}t Darmstadt Institut f{\"u}r Automatisierungstechnik und Mechatronik}, month = {9}, isbn = {978-3-9815012-2-3}, pages = {49--65}, address = {Anif/Salzburg, Austria}, }

Projektpartner und Förderung

26.06.2017 Backstepping-basierter Beobachterentwurf für parabolische PDGLn mit variablen Parametern

Projektschwerpunkte

- Zustandschätzung für lineare örtlich eindimensionale parabolische PDGLn mit orts- und zeitvariablen Parametern und zeitvariablen Randbedingungen

- Zustandschätzung für Systeme, die durch parabolische PDGLn in mehreren Ortsdimensionen beschrieben werden

- Zustandschätzung für quasi-lineare parabolische PDGLn mit lokal Lipschitz-stetigen Nichtlinearitäten

- Effiziente numerische Implementierung im Hinblick auf Echtzeitanwendungen

Beschreibung

Für moderne Regelungskonzepte – aber auch zur modellbasierten Überwachung der Prozessdynamik vieler technischer Anwendungen – ist sehr oft die Kenntnis des vollständigen Systemzustands erforderlich. Dies ist insbesondere dann notwendig, wenn die Regelung auf Basis einer Zustandsrückführung aufgebaut ist oder die vollständigen Zustandsinformationen zur modellbasierten Systemdiagnose und Störfallerkennung eingesetzt werden. Der vollständige Systemzustand kann jedoch in der Regel nicht unmittelbar durch Messungen erfasst werden. Dies trifft insbesondere auf verteilt-parametrische Systeme zu, die durch partielle Differenzialgleichungen (PDGLn) beschrieben werden, da hierbei Einschränkungen bezüglich der Anzahl der Messglieder zu berücksichtigen sind, oder im Fall örtlich mehrdimensionaler Systeme durch die Tatsache, dass Messungen oft nur am Rand des örtlichen Definitionsgebiets zur Verfügung stehen können. Aus diesem Grund wird ein Zustandsschätzer benötigt, um die nicht direkt messbaren Zustandsgrößen aus gemessenen Ein- und Ausgangsgrößen sowie der Kenntnis des mathematischen Modells zu bestimmen.

Dieses Projekt befasst sich mit dem Entwurf von Zustandsschätzern für Systeme, die durch parabolische PDGLn mit am Rand vorliegenden Messung modelliert werden. Dies erfolgt durch den Einsatz eines verteilt-parametrischen Luenberger-Beobachters mit in der PDGL und am Rand wirkenden Korrekturtermen, wobei zu deren Entwurf die Backstepping-Methodik herangezogen wird. Die so ermittelten Beobachterverstärkungen garantieren das exponentielle Abklingen der Beobachtungsfehlerdynamik und somit eine präzise Zustandsschätzung.

Ausgewählte Veröffentlichungen

- L. Jadachowski, T. Meurer, and A. Kugi, Backstepping Observers for linear PDEs on Higher-Dimensional Spatial Domains, Automatica, vol. 51, p. 85–97, 2015.

[BibTex]@Article{Jadachowski14a, author = {Jadachowski, L. and Meurer, T. and Kugi, A.}, title = {{Backstepping Observers for linear PDEs on Higher-Dimensional Spatial Domains}}, doi = {10.1016/j.automatica.2014.10.108}, pages = {85--97}, volume = {51}, journal = {Automatica}, year = {2015}, } - L. Jadachowski, T. Meurer, and A. Kugi, Backstepping Observers for Periodic Quasi-Linear Parabolic PDEs, in Proceedings of the 19th IFAC World Congress, Cape Town, South Africa, 2014, p. 7761–7766.

[BibTex]@InProceedings{Jadachowski14, author = {Jadachowski, L. and Meurer, T. and Kugi, A.}, booktitle = {Proceedings of the 19th IFAC World Congress}, title = {Backstepping Observers for Periodic Quasi-Linear Parabolic {PDE}s}, doi = {10.3182/20140824-6-ZA-1003.01246}, pages = {7761--7766}, address = {Cape Town, South Africa}, month = {8}, year = {2014}, } - L. Jadachowski, T. Meurer, and A. Kugi, State Estimation for Parabolic PDEs with Reactive-Convective Non-Linearities, in Proceedings of European Control Conference ECC 2013, Zürich, Switzerland, 2013, p. 1603 – 1608.

[BibTex] [Download]@InProceedings{Jadachowski13, author = {L. Jadachowski and T. Meurer and A. Kugi}, title = {State Estimation for Parabolic PDEs with Reactive-Convective Non-Linearities}, booktitle = {Proceedings of European Control Conference ECC 2013}, year = {2013}, month = {7}, pages = {1603 -- 1608}, url = {http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=6669588}, address = {Z\"{u}rich, Switzerland}, } - L. Jadachowski, T. Meurer, and A. Kugi, An Efficient Implementation of Backstepping Observers for Time-Varying Parabolic PDEs, in Proceedings MATHMOD 2012 Vienna, Wien, Austria, 2012, p. 798–803.

[BibTex]@InProceedings{Jadachowski12, author = {L. Jadachowski and T. Meurer and A. Kugi}, title = {{An Efficient Implementation of Backstepping Observers for Time-Varying Parabolic PDEs}}, booktitle = {Proceedings MATHMOD 2012 Vienna}, year = {2012}, editor = {Troch, I. and Breitenecker, F.}, month = {2}, pages = {798--803}, doi = {10.3182/20120215-3-AT-3016.00141}, address = {Wien, Austria}, } - L. Jadachowski, T. Meurer, and A. Kugi, State Estimation for Parabolic PDEs with Varying Parameters on 3-Dimensional Spatial Domains, in Proceedings of the 18th IFAC World Congress, Milano, Italia, 2011, pp. 13338-13343.

[BibTex]@InProceedings{Jadachowski11, author = {L. Jadachowski and T. Meurer and A. Kugi}, title = {{S}tate {E}stimation for {P}arabolic {PDE}s with {V}arying {P}arameters on 3-{D}imensional {S}patial {D}omains}, booktitle = {Proceedings of the 18th IFAC World Congress}, year = {2011}, month = {8}, pages = {13338-13343}, doi = {10.3182/20110828-6-IT-1002.02964}, address = {Milano, Italia}, } - L. Jadachowski, T. Meurer, and A. Kugi, State Reconstruction in Higher Dimensional PDEs with Spatially Varying Parameters, PAMM, Proceedings in Applied Mathematics and Mechanics, vol. 11, iss. 1, p. 813–814, 2011.

[BibTex]@Article{Jadachowski11a, Title = {{State Reconstruction in Higher Dimensional PDEs with Spatially Varying Parameters}}, Author = {L. Jadachowski and T. Meurer and A. Kugi}, Journal = {PAMM, Proceedings in Applied Mathematics and Mechanics}, Pages = {813--814}, Volume = {11}, Year = {2011}, Number = {1}, Doi = {10.1002/pamm.201110395}, }

Anwendungsbereiche

- Zustandsschätzung für Aufheiz- und Abkühlprozesse in der Stahlverarbeitung

- Systemüberwachung und -diagnose in Rohr- und Festbettreaktoren der Verfahrenstechnik

Förderung

TU Wien Doktorandenkolleg PDETech

Partner

Prof. Dr.-Ing. habil. Thomas Meurer

20.06.2017 Ebenheitsregelung bei der Grobblechwalzung

Projektscherpunkte

- Entwicklung von Modellen der viskoplastischen Materialverformung im Walzspalt

- Modellierung von Ebenheitsdefekten bei Walztafeln

- Entwurf von Regelungsstrategien zur Verbesserung der Ebenheit

Beschreibung

Die Kundenanforderungen an die Ebenheits- und Dickenqualität gewalzter Grobbleche steigen ständig. Die Produktqualität wird hauptsächlich durch die Walzung der Walztafeln an Reversierwalzgerüsten bestimmt. Hierbei werden die Walztafeln, in mehreren sogenannten Stichen, auf ihre Enddicke ausgewalzt. Zur Erhöhung der Produktqualität bieten sich physikalische Modelle und darauf aufbauende Regelungskonzepte an.

Walztafel mit Ebenheitsdefekt (Ski), © Dillinger Hüttenwerke AG.

Zur Einstellung der gewünschten Enddicke der Walztafel ist eine präzise Materialverfolgung vonnöten. Dazu wird ein analytisches Voreilungsmodell basierend auf der Annahme eines viskoplastischen Materialverhaltens hergeleitet. Die dabei hervorgehenden partiellen Differentialgleichungen lassen sich mittels geeigneter Koordinatentransformationen in geschlossener Form lösen.

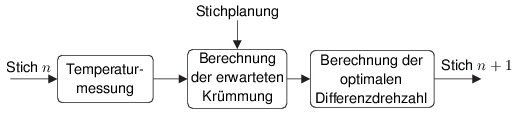

Berechnungschema zur Reduzierung der Skibildung.

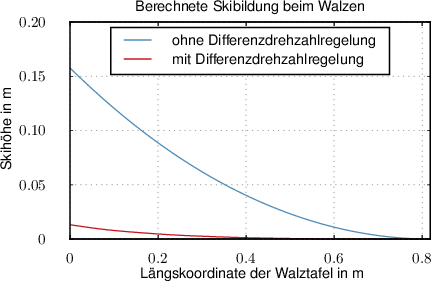

Beim Walzen von Grobblechen tritt unter Umständen ein ungewolltes Auf- oder Abbiegen der Walztafelenden auf. Dieser Ebenheitsdefekt wird aufgrund der Ähnlichkeit zur Spitze eines Skis auch als Ski-Effekt bezeichnet, vgl. Abb. 1. Die Ursachen für diesen Effekt sind Asymmetrien (u.a. Temperatur und Reibung) während des Walzens um die Mittelebene der Walztafel. Mit dem Traglastsatz der Plastizitätstheorie wird ein halbanalytisches Modell zur Ermittlung der Skibildung entwickelt.

Simulationsergebnisse zur Skibildung für einen Temperaturunterschied von 20 K zwischen Ober- und Unterseite der Walztafel.

Basierend auf der Modellierung der Skibildung erfolgt der Entwurf von Regelungskonzepten zur Verbesserung der Ebenheit. Dabei kommt eine Mehrgrößenregelung des Walzenantriebes zum Einsatz, welche eine gezielte Einstellung der Differenzdrehzahl zwischen oberer und unterer Arbeitswalze ermöglicht. Anhand des halbanalytischen Ski-Modells erfolgt die Ermittlung der einzustellenden Differenzdrehzahl zur Kompensation vorhandener Asymmetrien.

Ausgewählte Veröffentlichungen

- T. Kiefer, R. Heeg, and A. Kugi, Modellbasierte Dicken- und Ebenheitsregelung in Grobblechwalzwerken, at – Automatisierungstechnik, vol. 56, iss. 8, p. 416–426, 2008.

[BibTex] [Download]@Article{Kiefer08b, Title = {Modellbasierte {D}icken- und {E}benheitsregelung in {G}robblechwalzwerken}, Author = {T. Kiefer and R. Heeg and A. Kugi}, Journal = {at -- Automatisierungstechnik}, Pages = {416--426}, Volume = {56}, Year = {2008}, Number = {8}, Doi = {10.1524/auto.2008.0720}, } - T. Kiefer and A. Kugi, Model-based control in front-end bending in hot rolling processes, in Proceedings of the 17th IFAC World Congress, Seoul, Korea, 2008, p. 1645–1650.

[BibTex]@InProceedings{Kiefer08, author = {T. Kiefer and A. Kugi}, title = {Model-based control in front-end bending in hot rolling processes}, booktitle = {Proceedings of the 17th IFAC World Congress}, year = {2008}, month = {7}, pages = {1645--1650}, doi = {10.3182/20080706-5-KR-1001.00280}, address = {Seoul, Korea}, } - T. Kiefer and A. Kugi, An Analytical Approach for Modelling Asymmetrical Hot Rolling of Heavy Plates, Mathematical and Computer Modelling of Dynamical Systems, vol. 14, iss. 3, p. 249–267, 2008.

[BibTex] [Download]@Article{Kiefer08a, Title = {An Analytical Approach for Modelling Asymmetrical Hot Rolling of Heavy Plates}, Author = {T. Kiefer and A. Kugi}, Journal = {Mathematical and Computer Modelling of Dynamical Systems}, Pages = {249--267}, Volume = {14}, Year = {2008}, Number = {3}, Doi = {10.1080/13873950701844915}, } - T. Kiefer and A. Kugi, Modelling and Control of Front End Bending in Heavy Plate Mills, in Proceedings of the 12th IFAC Symposium on Automation in Mining, Mineral and Metal Processing, Quebec City, Canada, 2007, p. 231–236.

[BibTex]@InProceedings{Kiefer07, author = {T. Kiefer and A. Kugi}, title = {Modelling and Control of Front End Bending in Heavy Plate Mills}, booktitle = {Proceedings of the 12th IFAC Symposium on Automation in Mining, Mineral and Metal Processing}, year = {2007}, month = {8}, pages = {231--236}, doi = {10.3182/20070821-3-CA-2919.00034}, address = {Quebec City, Canada}, }

Anwendungsbereiche

- Walzwerksautomatisierung

20.06.2017 Modellierung und Regelung von Warmrichtmaschinen

Projektschwerpunkte

- Modellbildung und -identifikation von mechanischen und hydraulischen Maschinenkomponenten

- Optimierungsbasierte, aktive Kompensation der elastischen Auffederung

- Reglerentwurf zur dynamischen Maschinenanstellung

Beschreibung

Warmrichtmaschinen werden bei der Blechherstellung in Walzwerken eingesetzt. Das Richten folgt im Produktionsablauf nach dem Walzen und Kühlen, um verbliebene Ebenheitsdefekte und Resteigenspannungen der Walztafeln zu reduzieren. Dazu werden die Walztafeln an Richtmaschinen durch wechselseitiges Überbiegen plastisch verformt.

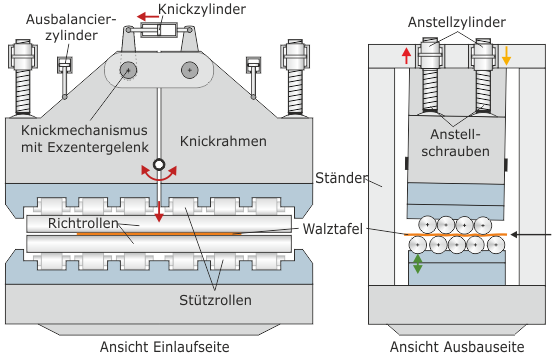

Warmrichtmaschine mit Knickmechanismus.

Beim Richten von Grobblechen treten Prozesskräfte von einigen Meganewton auf, die zu einer elastischen Auffederung der Maschine im Bereich von mehreren Millimetern führen. Zur Einhaltung der Richtqualität muss diese Auffederung kompensiert werden, z.B. mit Hilfe von Aktoren oder einem Knickmechanismus. Gleichzeitig muss die Maschine vor Überlastung geschützt werden.

Daher sind hier die Analyse und die mathematische Modellierung des mechanischen und hydraulischen Aufbaus der Richtmaschine von Interesse. Die Schwerpunkte der Modellierung sind die elastische Auffederung der Maschinenkomponenten sowie Reibeffekte in den hydraulischen Aktoren und den Gelenken des Knickmechanismus.

Der Ausgangspunkt des mathematischen Auffederungsmodells ist ein Euler-Bernoulli-Balken-Modell der Richtrollen. Die elastische Abstützung der Richtrollen durch die Stützrollen, den Rahmen und die Ständer wird mit Nachgiebigkeitsmatrizen abgebildet. Das Modell wurde mit Hilfe instrumentierter Bleche validiert. Ein reduziertes finit-dimensionales Modell bildet die Grundlage der Berechnung einer optimalen Auffederungskompensation. Ein Optimierungsalgorithmus ermittelt die Anstellung der Aktoren so, dass die gewünschte Position und Form der Richtrollen und damit die gewünschte Walztafelkrümmung bestmöglich eingestellt wird. Dabei wird direkt im Optimierungsverfahren die mechanische Belastung der Maschinenkomponenten berücksichtigt und somit eine Überlastung der Richtmaschine vermieden. Zur Ermittlung der Verformungskräfte an der Walztafel steht ein nichtlineares Richtmodell zur Verfügung.

Die gezielte Krümmung der Richtrollen mit Hilfe des Knickmechanismus der Richtmaschine ist entscheidend für eine genaue Auffederungskompensation. Auf Basis eines validierten dynamischen Modells des Knickmechanismus wurde eine Regelung der Knickrahmen-Anstellung entwickelt, die eine gewünschte Richtrollenkrümmung auch unter der Wirkung der Richtkraft und Reibung in den Gelenken verlässlich einstellt.

Die entwickelten Lösungen konnten bereits erfolgreich an einer industriellen Warmrichtmaschine für Grobbleche in Betrieb genommen werden.

Ausgewählte Veröffentlichungen

- R. Brauneis, M. Baumgart, A. Steinboeck, and A. Kugi, Deflection Model Of A Multi-Actuator Gap Leveler, in Proceedings of the 20th IFAC World Congress, Toulouse, France, 2017, pp. 11295-11300.

[BibTex] [Download]@InProceedings{Brauneis17, author = {Brauneis, R. and Baumgart, M. and Steinboeck, A. and Kugi, A.}, title = {Deflection Model Of A Multi-Actuator Gap Leveler}, booktitle = {Proceedings of the 20th IFAC World Congress}, year = {2017}, volume = {50}, number = {1}, month = {7}, pages = {11295-11300}, doi = {10.1016/j.ifacol.2017.08.1647}, address = {Toulouse, France}, issn = {2405-8963}, } - M. Baumgart, A. Steinboeck, T. Kiefer, and A. Kugi, Modelling and experimental validation of the deflection of a leveller for hot heavy plates, Mathematical and Computer Modelling of Dynamical Systems, vol. 21, iss. 3, p. 202–227, 2015.

[BibTex] [Download]@Article{Baumgart15a, Title = {Modelling and experimental validation of the deflection of a leveller for hot heavy plates}, Author = {Baumgart, M. and Steinboeck, A. and Kiefer, T. and Kugi, A.}, Journal = {Mathematical and Computer Modelling of Dynamical Systems}, Pages = {202--227}, Volume = {21}, Year = {2015}, Number = {3}, Doi = {10.1080/13873954.2014.941881}, } - M. Baumgart, A. Steinboeck, A. Kugi, G. Raffin-Peyloz, L. Irastroza, and T. Kiefer, Optimal Active Deflection Compensation of a Hot Leveler, in Proceedings of the IFAC Workshop on Automation in the Mining, Mineral and Metal Industries, Gifu, Japan, 2012, p. 30 – 35.

[BibTex]@InProceedings{Baumgart12, author = {M. Baumgart and A. Steinboeck and A. Kugi and G. Raffin-Peyloz and L. Irastroza and T. Kiefer}, title = {{O}ptimal {A}ctive {D}eflection {C}ompensation of a {H}ot {L}eveler}, booktitle = {Proceedings of the IFAC Workshop on Automation in the Mining, Mineral and Metal Industries}, year = {2012}, month = {9}, pages = {30 -- 35}, doi = {10.3182/20120910-3-JP-4023.00009}, address = {Gifu, Japan}, } - M. Baumgart, A. Steinboeck, A. Kugi, B. Douanne, G. Raffin-Peyloz, L. Irastroza, and T. Kiefer, Modeling and Active Compensation of the Compliance of a Hot Leveler, steel research international, vol. Special Edition ICTP2011, p. 337–342, 2011.

[BibTex]@Article{Baumgart11a, Title = {{Modeling and Active Compensation of the Compliance of a Hot Leveler}}, Author = {M. Baumgart and A. Steinboeck and A. Kugi and B. Douanne and G. Raffin-Peyloz and L. Irastroza and T. Kiefer}, Journal = {steel research international}, Pages = {337--342}, Volume = {Special Edition ICTP2011}, Year = {2011}, } - M. Baumgart, A. Steinboeck, A. Kugi, G. Raffin-Peyloz, B. Douanne, L. Irastorza, and T. Kiefer, Active compliance compensation of a hot leveler, in Proceedings of the 4th International Conference on Modelling and Simulation of Metallurgical Processes in Steelmaking, STEELSIM, METEC InSteelCon 2011, Düsseldorf, Germany, 2011.

[BibTex]@InProceedings{Baumgart11, author = {M. Baumgart and A. Steinboeck and A. Kugi and G. Raffin-Peyloz and B. Douanne and L. Irastorza and T. Kiefer}, title = {Active compliance compensation of a hot leveler}, booktitle = {Proceedings of the 4th International Conference on Modelling and Simulation of Metallurgical Processes in Steelmaking, STEELSIM, METEC InSteelCon 2011}, year = {2011}, month = {6}, address = {D\"usseldorf, Germany}, }

Anwendungsbereiche

- Walzwerksautomatisierung

- Umformmaschinen

19.06.2017 Modellierung, Beobachterentwurf, Regelung und Optimierung von Bandglühöfen

Projektschwerpunkte

- Mathematische Modellbildung für Bandglühöfen

- Beobachterentwurf zur Schätzung nicht messbarer Prozessgrößen

- Entwicklung einer modernen Regelungsstrategie für die Erwärmung des Bandes

Beschreibung

In der Stahlindustrie werden Durchlaufglühöfen zur Wärmebehandlung von Bandprodukten verwendet. Um einen kontinuierlichen Betrieb solcher Glühöfen zu gewährleisten, werden die Stahlbänder aneinandergeschweißt und als Endlosband durch den Ofen befördert. Die Wärmebehandlung verbraucht große Mengen an Energie, ist kostenintensiv und hat direkte Auswirkungen auf die Produktqualität.

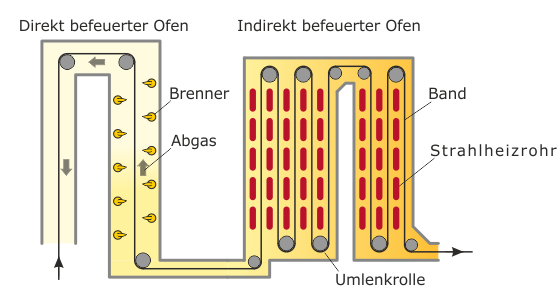

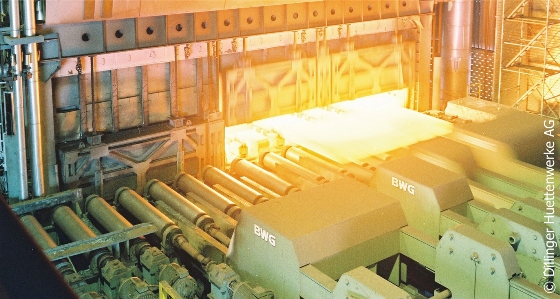

Kombiniert direkt und indirekt befeuerter Bandglühofen.

Um die hohen Anforderungen an die Qualität des Endprodukts zu erfüllen, muss jedes Band im Glühofen auf eine definierte Zieltemperatur erwärmt werden. Da es sich bei einem Glühofen um ein komplexes thermodynamisches Mehrgrößensystem mit vielfältigen Abhängigkeiten handelt, ist die Regelung der Bandtemperatur eine anspruchsvolle Aufgabe. Diese Aufgabe wird durch eine geringe Anzahl verfügbarer Messungen, Beschränkungen der Eingangs- und Prozessgrößen, einer zunehmenden Diversifikation des Produktportfolios sowie steigenden Anforderungen hinsichtlich Produktqualität und Durchsatz erschwert.

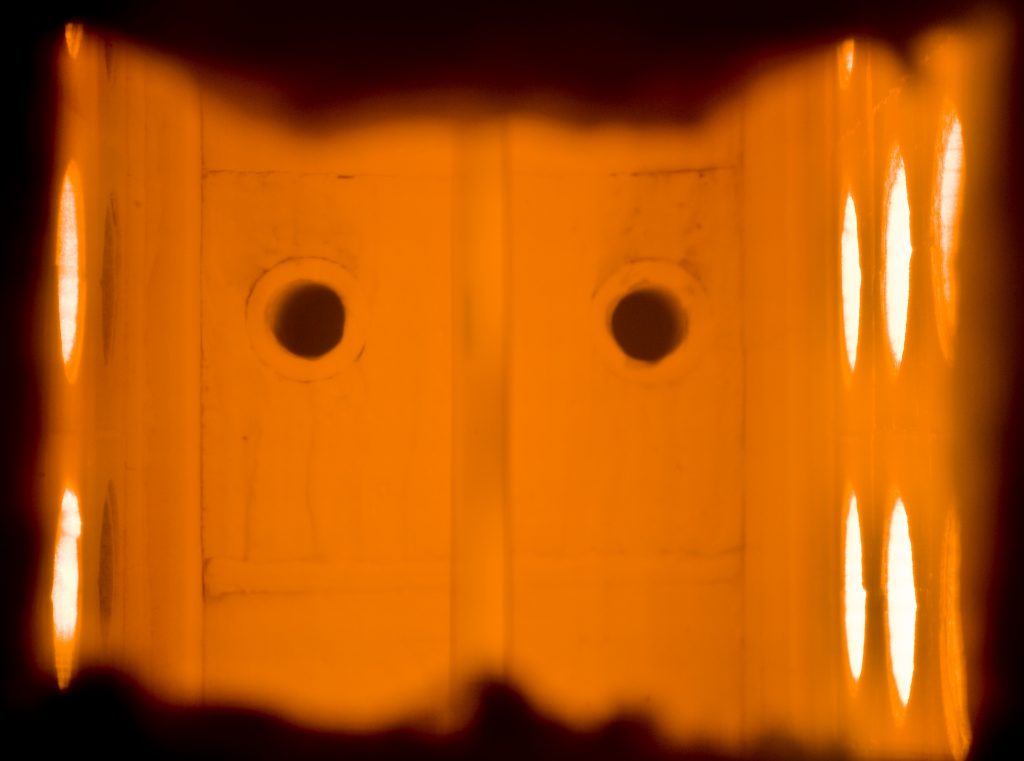

Brenner und Band im direkt befeuerten Bandglühofen, © voestalpine AG.

In diesem Projekt wurde ein optimierungsbasiertes Regelungskonzept für die Bandtemperatur in einem kombiniert direkt- und indirekt-befeuerten Glühofen entwickelt und an einer Pilotanlage der voestapline Stahl GmbH am Standort Linz umgesetzt. Der nichtlineare modellprädiktive Regler bestimmt optimale Trajektorien für die Brennstoffzufuhr und die Bandgeschwindigkeit so, dass die Bandtemperatur ihrem Sollsignal folgt. Darüber hinaus maximiert der Regler den Produktdurchsatz und minimiert den Energieverbrauch.

Kontinuierlicher Bandglühofen, © voestalpine AG.

Die Grundlage dieses Regelungskonzepts ist ein mathematisches Modell für die Bandtemperatur. Für die Formulierung dieses Modells wurden Mol-, Massen- und Enthalpiebilanzen, Konstitutivgleichungen und numerische Diskretisierungsverfahren verwendet. Zur Schätzung nicht messbarer Prozessgrößen sowie unbekannter Materialparameter, wie z.B. der Bandemissivität, wird ein ad-hoc Zustandsbeobachter verwendet.

Ausgewählte Veröffentlichungen

- S. Strommer, C. Froehlich, M. Niederer, A. Steinboeck, and A. Kugi, Modeling and Control of the Oxygen Concentration in a Post Combustion Chamber of a Gas-Fired Furnace, in Proceedings of the 20th IFAC World Congress, Toulouse, France, 2017, p. 13766–13771.

[BibTex]@InProceedings{Strommer17a, author = {Strommer, S. and Froehlich, C. and Niederer, M. and Steinboeck, A. and Kugi, A.}, title = {Modeling and Control of the Oxygen Concentration in a Post Combustion Chamber of a Gas-Fired Furnace}, booktitle = {Proceedings of the 20th IFAC World Congress}, year = {2017}, volume = {50}, number = {1}, month = {7}, pages = {13766--13771}, doi = {10.1016/j.ifacol.2017.08.1651}, address = {Toulouse, France}, issn = {2405-8963}, } - C. Fröhlich, S. Strommer, A. Steinboeck, M. Niederer, and A. Kugi, Modeling of the Media-Supply of Gas Burners of an Industrial Furnace, IEEE Transactions on Industry Applications, vol. 52, iss. 3, pp. 2664-2672, 2016.

[BibTex] [Download]@Article{Froehlich16, Title = {Modeling of the Media-Supply of Gas Burners of an Industrial Furnace}, Author = {Fr{\"o}hlich, Christoph and Strommer, S. and Steinboeck, A. and Niederer, M. and Kugi, A.}, Journal = {IEEE Transactions on Industry Applications}, Pages = {2664-2672}, Volume = {52}, Year = {2016}, Number = {3}, Doi = {10.1109/TIA.2016.2521738}, ISSN = {0093-9994}, Publisher = {IEEE}, } - F. Maislinger, M. Niederer, A. Steinboeck, S. Strommer, and A. Kugi, A Mathematical Model of a Horizontal Direct-Fired Strip Annealing Furnace, in Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM), Vienna, Austria, 2016, p. 202–207.

[BibTex]@InProceedings{Maislinger16, author = {Maislinger, F. and Niederer, M. and Steinboeck, A. and Strommer, S. and Kugi, A.}, title = {A Mathematical Model of a Horizontal Direct-Fired Strip Annealing Furnace}, booktitle = {Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM)}, year = {2016}, volume = {49}, number = {20}, month = {8}, pages = {202--207}, doi = {10.1016/j.ifacol.2016.10.121}, address = {Vienna, Austria}, issn = {2405-8963}, } - M. Niederer, S. Strommer, A. Steinboeck, and A. Kugi, Nonlinear model predictive control of the strip temperature in an annealing furnace, Journal of Process Control, vol. 48, p. 1–13, 2016.

[BibTex] [Download]@Article{Niederer16, Title = {Nonlinear model predictive control of the strip temperature in an annealing furnace}, Author = {Niederer, M. and Strommer, S. and Steinboeck, A. and Kugi, A.}, Journal = {Journal of Process Control}, Pages = {1--13}, Volume = {48}, Year = {2016}, Doi = {10.1016/j.jprocont.2016.09.012}, ISSN = {0959-1524}, } - S. Strommer, M. Niederer, A. Steinboeck, L. Jadachowski, and A. Kugi, Nonlinear observer for temperatures and emissivities in a strip annealing furnace, in Proceedings of the IEEE Industry Applications Society Annual Meeting, Portland, USA, 2016, p. 1–8.

[BibTex]@InProceedings{Strommer16a, author = {Strommer, S. and Niederer, M. and Steinboeck, A. and Jadachowski, L. and Kugi, A.}, booktitle = {Proceedings of the IEEE Industry Applications Society Annual Meeting}, title = {Nonlinear observer for temperatures and emissivities in a strip annealing furnace}, doi = {10.1109/IAS.2016.7731914}, isbn = {978-1-4799-8397-1}, pages = {1--8}, address = {Portland, USA}, month = {10}, year = {2016}, } - S. Strommer, M. Niederer, A. Steinboeck, and A. Kugi, Combustion Processes Inside a Direct-Fired Continuous Strip Annealing Furnace, in Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM), Vienna, Austria, 2016, p. 208–213.

[BibTex]@InProceedings{Strommer16, author = {Strommer, S. and Niederer, M. and Steinboeck, A. and Kugi, A.}, title = {Combustion Processes Inside a Direct-Fired Continuous Strip Annealing Furnace}, booktitle = {Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM)}, year = {2016}, volume = {49}, number = {20}, month = {8}, pages = {208--213}, doi = {10.1016/j.ifacol.2016.10.122}, address = {Vienna, Austria}, issn = {2405-8963}, } - M. Niederer, S. Strommer, A. Steinboeck, and A. Kugi, A simple control-oriented model of an indirect-fired strip annealing furnace, International Journal of Heat and Mass Transfer, vol. 78, p. 557–570, 2014.

[BibTex] [Download]@Article{Niederer14, Title = {A simple control-oriented model of an indirect-fired strip annealing furnace}, Author = {Niederer, M. and Strommer, S. and Steinboeck, A. and Kugi, A.}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {557--570}, Volume = {78}, Year = {2014}, Doi = {10.1016/j.ijheatmasstransfer.2014.06.080}, } - S. Strommer, M. Niederer, A. Steinboeck, and A. Kugi, A mathematical model of a direct-fired continuous strip annealing furnace, International Journal of Heat and Mass Transfer, vol. 69, p. 375–389, 2014.

[BibTex] [Download]@Article{Strommer14, Title = {{A mathematical model of a direct-fired continuous strip annealing furnace}}, Author = {S. Strommer and M. Niederer and A. Steinboeck and A. Kugi}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {375--389}, Volume = {69}, Year = {2014}, Doi = {10.1016/j.ijheatmasstransfer.2013.10.001}, }

Anwendungsbereiche

- Industrieöfen

- Kontinuierliche Produktionssysteme

16.06.2017 Modellierung und Regelung eines Quarto-Reversiergerüstes zum Walzen von Grobblechen

Projektschwerpunkte

- Modellbildung, Identifikation und Analyse von mechanischen und hydraulischen Komponenten eines Fertiggerüstes

- Regelung von Warmwalzgerüsten (Feedforward-Dickenregelung)

- Online-Adaption von Modellparametern für die modellbasierte Reglung

Beschreibung

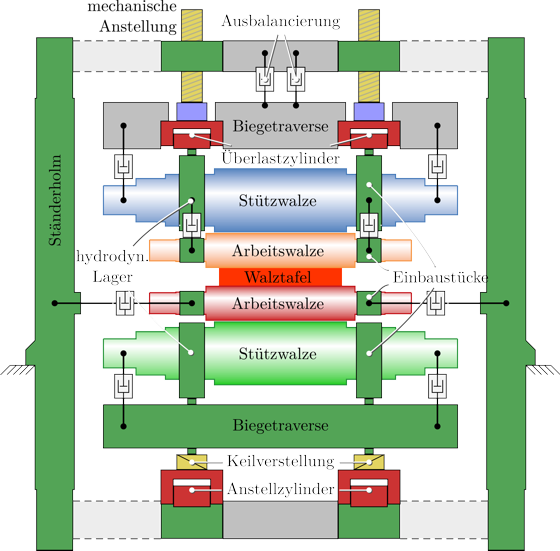

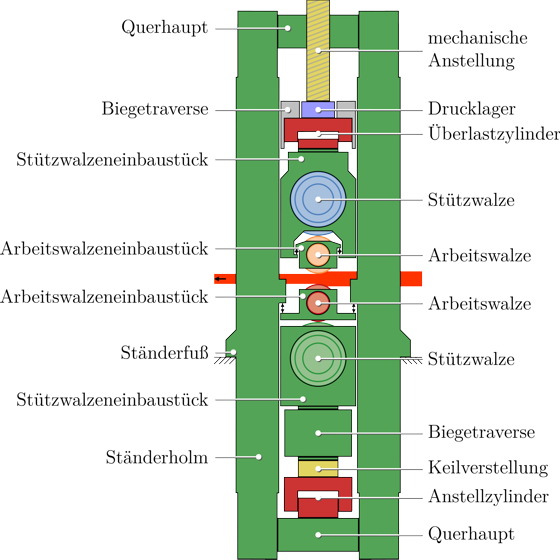

Beim Warmwalzen von Grobblechen werden die zuvor erwärmten Walztafeln mit Hilfe von Walzgerüsten umgeformt. Dabei werden häufig Quarto-Reversiergerüste eingesetzt, die aus zwei Arbeitswalzen und zwei Stützwalzen aufgebaut sind. Die plastische Umformung der Walztafel findet in mehreren Stichen zwischen den beiden Arbeitswalzen statt. Aufgrund der hohen Walzkräfte kommt es zu einer Durchbiegung der Arbeitswalzen, was ein ungleichmäßiges Dickenprofil der Walztafel zur Folge hat. Die beiden Stützwalzen sollen eine solche Durchbiegung der Arbeitswalzen verringern. Zusätzlich sind die Gerüste häufig mit Gegenbiegevorrichtungen in Form von hydraulischen Gegenbiegern und/oder speziell geschliffenen Walzen (CVC-Walzen) ausgestattet. Damit soll ein ebener Walzspalt und somit ein gleichmäßiges laterales Dickenprofil im Endprodukt erzielt werden.

Quarto-Reversierwalzgerüst, © Dillinger Hüttenwerke AG.

Während des Walzens treten Kräfte von bis zu 90 MN auf, die zu elastischen Verformungen des Gerüstes von bis zu 13 mm führen können. Diese Auffederung setzt sich aus der elastischen Deformation des Gerüstständers sowie der Durchbiegung und Kompression der Walzen zusammen. Da beim Walzen die gewünschte Dicke der Walztafel mit einer Genauigkeit von 0.1 mm erreicht werden muss, ist es notwendig, diese Auffederung zu kompensieren. Das Gerüst muss zudem so eingestellt werden, dass ein möglichst ebener Walzspalt zwischen den Arbeitswalzen entsteht, sodass die Walztafel in lateraler Richtung eine konstante Auslaufdicke aufweist. Aufgrund der Bedingungen rund um den Walzspalt (Hitze, Wasserdampf) ist es jedoch nicht möglich, die Auslaufdicke der Walztafel unmittelbar am Walzspalt zu messen. Eine Dickenmessung erfolgt erst einige Meter vom Gerüst entfernt. Diese Messung kann aufgrund der zeitlichen Verzögerung nicht für die Dickenregelung des Walzvorganges verwendet werden. Es ist daher notwendig, die Auslaufdicke der Walztafel mit Hilfe eines Modells zu berechnen. Bei der Modellierung müssen einerseits die hydraulischen und mechanischen Komponenten des Ständers, andererseits – insbesondere für die Auslaufdicke in lateraler Richtung – die Biegung und die Kompression der Walzen berücksichtigt werden. Die Ergebnisse dieses Modells können dann für die Regelung verwendet werden.

Aufbau eines Quarto-Reversierwalzgerüstes – Frontansicht.

Aufgrund der Dimension der Walzen wurde als Ausgangspunkt des mathematischen Modells für die Biegung der Arbeits- und Stützwalzen ein Timoshenko-Balkenmodell gewählt. Zur vollständigen Beschreibung des Problems müssen die Belastungen der Walzen und die Randbedingungen bestimmt werden.

Die Walzkraft, die zwischen den beiden Arbeitswalzen wirkt, ist die Kraft, die zur plastischen Umformung des Walzgutes führt. Diese Kraft hängt vom Material der Walztafel, der Walzgeschwindigkeit, dem Temperaturprofil sowie dem Einlauf- und Auslaufdickenprofil der Walztafel ab. Da die Auslaufdicke von der Durchbiegung der beiden Arbeitswalzen abhängig ist, ergibt sich eine nichtlineare Kopplung der Differentialgleichungen der beiden Arbeitswalzen.

Ähnliches gilt für den Kontakt zwischen den Stütz- und Arbeitswalzen. Man erhält einen nichtlinearen Zusammenhang zwischen der Kontaktkraft und der Verschiebung der Achsen der Stütz- und Arbeitswalzen.

Zur Festlegung von Randbedingungen ist es notwendig, den Abstand der beiden Stützwalzenzapfen zu ermitteln. Dies setzt neben einer Kalibration des Modells die Berechnung der Auffederung des Gerüstes voraus, die von der Walzkraft abhängig ist. Hierbei müssen auch die Reibkräfte, die zwischen den Walzeneinbaustücken und den Ständerholmen wirken, berücksichtigt werden. Des Weiteren muss die Position der Stützwalzenzapfen in den hydrodynamischen Lagern bestimmt werden, wobei sich eine nichtlineare Abhängigkeit von der Walzkraft und der Walzgeschwindigkeit ergibt.

Letztlich ist ein 2-Punkt-Randwertproblem aus 16 gekoppelten nichtlinearen Differentialgleichungen zu lösen. Da das Modell zur Echtzeitregelung verwendet werden soll, darf die Rechenzeit zur Lösung des Problems die Abtastzeit der Dickenregelung nicht überschreiten.

Die entwickelte Lösung wurde erfolgreich anhand von Messdaten eines industriellen Fertiggerüstes verifiziert.

Aufbau eines Quarto-Reversierwalzgerüstes – Seitenansicht.

Wird ein solches Modell im Rahmen einer herkömmlichen Regelungsstrategie eingesetzt, so ist es aufgrund der begrenzten Dynamik der Anstellvorrichtung und des geschlossenen Regelkreises nur schwer möglich, schnelle Störungen der Einlaufdicke und der Umformfestigkeit der Walztafel zu kompensieren. Schwankungen in der Umformfestigkeit können z.B. aufgrund von Unregelmäßigkeiten in der Temperaturverteilung der Walztafel auftreten.

Es wurden nun Strategien zur Schätzung des Einlaufdicken- und Umformfestigkeitsprofils während eines Stiches entwickelt. Diese geschätzten Profile werden im folgenden Stich im Sinne einer Vorsteuerung auf den kaskadierten konventionellen Dickenregelkreis aufgeschaltet. Man erhält eine Kombination einer Feedforward-Regelungsstrategie mit der üblichen Gaugemeter-Methode zur Auffederungskompensation, mit deren Hilfe die Schwankungen in den Eingangsgrößen zumindest teilweise kompensiert werden können.

Die entwickelte Feedforward-Regelungsstrategie wurde nach Verifikation in der Simulationsumgebung an einer industriellen Anlage implementiert, wo sie erfolgreich weiterentwickelt wird.

Ausgewählte Veröffentlichungen

- T. König, Entwicklung, Parametrierung und Online-Adaption eines mathematischen Modells eines Walzgerüstes beim Warmwalzen, A. Kugi and K. Schlacher, Eds., Aachen: Shaker Verlag, 2014, vol. 22.

[BibTex]@Book{Koenig14, Title = {Entwicklung, {P}arametrierung und {O}nline-{A}daption eines mathematischen {M}odells eines {W}alzger{\"u}stes beim {W}armwalzen}, Author = {K{\"o}nig, T.}, Editor = {A. Kugi and K. Schlacher}, Publisher = {Shaker Verlag}, Year = {2014}, Address = {Aachen}, Series = {Modellierung und Regelung komplexer dynamischer Systeme}, Volume = {22}, ISBN = {978-3-8440-3224-6}, Organization = {Institute f{\"u}r Automatisierungs- und Regelungstechnik (TU Wien) und Regelungstechnik und Prozessautomatisierung (JKU Linz)}, } - T. König, A. Steinboeck, and A. Kugi, Online Calibration of a Mathematical Model for the Deflection of a Rolling Mill, in Proceedings of Rolling 2013, Venezia, Italy, 2013, p. 1–12.

[BibTex]@InProceedings{Konig13, author = {T. K{\"o}nig and A. Steinboeck and A. Kugi}, title = {{{O}nline {C}alibration of a {M}athematical {M}odel for the {D}eflection of a {R}olling {M}ill}}, booktitle = {Proceedings of Rolling 2013}, year = {2013}, month = {6}, pages = {1--12}, address = {Venezia, Italy}, } - T. König, A. Steinboeck, A. Kugi, R. Heeg, and T. Kiefer, Deflection and bending model of a four-high mill stand for heavy plate rolling, in Proceedings of the 4th International Conference on Modelling and Simulation of Metallurgical Processes in Steelmaking, STEELSIM, METEC InSteelCon 2011, Düsseldorf, Germany, 2011.

[BibTex]@InProceedings{Koenig11, author = {T. K\"onig and A. Steinboeck and A. Kugi and R. Heeg and T. Kiefer}, title = {Deflection and bending model of a four-high mill stand for heavy plate rolling}, booktitle = {Proceedings of the 4th International Conference on Modelling and Simulation of Metallurgical Processes in Steelmaking, STEELSIM, METEC InSteelCon 2011}, year = {2011}, month = {6}, address = {D\"usseldorf, Germany}, } - R. Heeg, Modellierung und Dickenregelung beim Warmwalzen, A. Kugi and K. Schlacher, Eds., Aachen: Shaker Verlag, 2009, vol. 5.

[BibTex]@Book{Heeg09, Title = {Modellierung und Dickenregelung beim Warmwalzen}, Author = {R. Heeg}, Editor = {A. Kugi and K. Schlacher}, Publisher = {Shaker Verlag}, Year = {2009}, Address = {Aachen}, Series = {Modellierung und Regelung komplexer dynamischer Systeme}, Volume = {5}, ISBN = {978-3-8322-7871-7}, } - T. König, Mathematische Modelle zur Berechnung der Auffederung eines Fertiggerüstes, 2008.

[BibTex]@Mastersthesis{koenig08, Title = {Mathematische Modelle zur Berechnung der Auffederung eines Fertigger{\"u}stes}, Author = {K{\"o}nig, T.}, School = {Vienna University of Technology}, Year = {2008}, } - R. Heeg, T. Kiefer, and A. Kugi, Control of Plate Thickness in Heavy Plate Mills: A New Perspective, in Proceedings of the 12th IFAC Symposium on Automation in Mining, Mineral and Metal Processing, Quebec City, Canada, 2007, p. 107–112.

[BibTex]@InProceedings{Heeg07, author = {R. Heeg and T. Kiefer and A. Kugi}, title = {Control of Plate Thickness in Heavy Plate Mills: A New Perspective}, booktitle = {Proceedings of the 12th IFAC Symposium on Automation in Mining, Mineral and Metal Processing}, year = {2007}, month = {8}, pages = {107--112}, doi = {10.3182/20070821-3-CA-2919.00016}, address = {Quebec City, Canada}, }

Anwendungsbereiche

- Walzwerksautomatisierung

- Plastischer Umformprozess

- Warmwalzen von Grobblechen

14.06.2017 Laterale Führung und Formgebung beim Grobblechwalzen

Projektschwerpunkte

- Modellierung des Geradeauslaufs und der Konturentwicklung von Walztafeln

- Entwicklung einer Messeinrichtung zur kontinuierlichen Ermittlung der Walztafelkontur

- Entwurf von Regelungsstrategien zur Reduktion von Geometrieabweichungen

Beschreibung

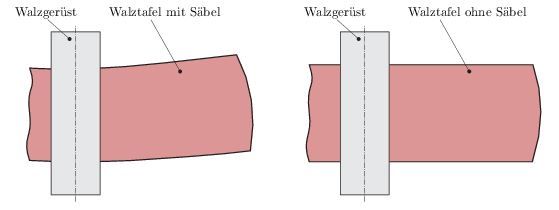

Im Walzwerk werden Brammen mittels Reversierwalzgerüsten zu Grobblechen mit einer bestimmten Produktdicke ausgewalzt. Dabei können bedingt durch den Walzprozess unerwünschte, geometrische Abweichungen um die Hochachse der Walztafel (Säbel) auftreten. Außerdem kann es zu Abweichungen von der geradlinigen Bewegung der Walztafel durch den Walzspalt kommen. Stetig steigende Qualitätsanforderungen an die Produkte verlangen eine Minimierung solcher Nichtidealitäten.

Walztafel mit und ohne Säbel (Draufsicht).

Zur Simulation der Entstehung des Säbels beim Walzprozess werden mathematische Modelle verwendet. Hierbei kommen kontinuumsmechanische Modelle zum Einsatz, die ausgehend von der plastischen Verformung im Walzspalt die Resteigenspannungen und die Konturevolution liefern. Anhand der Modelle lassen sich verschiedene Einflussfaktoren auf die Säbelbildung untersuchen und mögliche Optimierungspotenziale am Gerüst identifizieren.

Quarto-Reversierwalzgerüst, © Dillinger Hüttenwerke AG.

Zur Detektion und Charakterisierung vorhandener Säbel wird eine kamerabasierte Messeinrichtung verwendet. Diese erfasst in Echtzeit neben der Kontur auch die Bewegung der Walztafel während des Stiches. Die Messverfahren müssen den widrigen Umgebungsbedingungen am Walzgerüst standhalten. Zusätzlich stellt die Realisierung einer möglichst verzögerungsfreien Messung eine Herausforderung dar.

Basierend auf der Modellierung der Säbelbildung werden Regelungs- und Optimierungsstrategien zur Reduktion vorhandener Säbel erstellt. Hierbei können verschiedene Stelleingriffe am Walzgerüst genutzt werden, um unter Einhaltung zusätzlicher Anforderungen (z.B. Dicke des Endproduktes) und Gewährleistung des Geradeauslaufs die gewünschte Form der Walztafel einzustellen.

Die entwickelten Lösungen wurden erfolgreich an einem Grobblech Walzgerüst implementiert und werden dort nun im Dauerbetrieb genützt.

Ausgewählte Veröffentlichungen

- F. Schausberger, A. Steinboeck, and Kugi, Optimization-based reduction of contour errors of heavy plates in hot rolling, Journal of Process Control, vol. 47, p. 150–160, 2016.

[BibTex] [Download]@Article{Schausberger16a, Title = {Optimization-based reduction of contour errors of heavy plates in hot rolling}, Author = {Schausberger, F. and Steinboeck, A. and Kugi}, Journal = {Journal of Process Control}, Pages = {150--160}, Volume = {47}, Year = {2016}, Doi = {10.1016/j.jprocont.2016.09.010}, ISSN = {0959-1524}, } - F. Schausberger, A. Steinboeck, A. Kugi, M. Jochum, D. Wild, and T. Kiefer, Vision-Based Material Tracking in Heavy-Plate Rolling, in Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM), Vienna, Austria, 2016, p. 108–113.

[BibTex] [Download]@InProceedings{Schausberger16, author = {Schausberger, F. and Steinboeck, A. and Kugi, A. and Jochum, M. and Wild, D. and Kiefer, T.}, title = {Vision-Based Material Tracking in Heavy-Plate Rolling}, booktitle = {Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM)}, year = {2016}, volume = {49}, number = {20}, month = {8}, pages = {108--113}, doi = {10.1016/j.ifacol.2016.10.105}, address = {Vienna, Austria}, issn = {2405-8963}, } - F. Schausberger, K. Speicher, A. Steinboeck, M. Jochum, and A. Kugi, Two Illustrative Examples to Show the Potential of Thermography for Process Monitoring and Control in Hot Rolling, in Proceedings of the 4th IFAC Workshop on Mining, Mineral and Metal Processing (MMM), Oulu, Finland, 2015, p. 48–53.

[BibTex] [Download]@InProceedings{Schausberger15c, author = {Schausberger, F. and Speicher, K. and Steinboeck, A. and Jochum, M. and Kugi, A.}, title = {Two Illustrative Examples to Show the Potential of Thermography for Process Monitoring and Control in Hot Rolling}, booktitle = {Proceedings of the 4th IFAC Workshop on Mining, Mineral and Metal Processing (MMM)}, year = {2015}, volume = {48}, number = {17}, month = {8}, pages = {48--53}, doi = {10.1016/j.ifacol.2015.10.076}, address = {Oulu, Finland}, issn = {2405-8963}, } - F. Schausberger, A. Steinboeck, and A. Kugi, Mathematical modeling of the contour evolution of heavy plates in hot rolling, Applied Mathematical Modelling, vol. 39, p. 4534–4547, 2015.

[BibTex] [Download]@Article{Schausberger15, Title = {Mathematical modeling of the contour evolution of heavy plates in hot rolling}, Author = {Schausberger, F. and Steinboeck, A. and Kugi, A.}, Journal = {Applied Mathematical Modelling}, Pages = {4534--4547}, Volume = {39}, Year = {2015}, Doi = {10.1016/j.apm.2015.01.017}, } - F. Schausberger, A. Steinboeck, and A. Kugi, Optimization-based estimator for the contour and movement of heavy plates in hot rolling, Journal of Process Control, vol. 29, p. 23–32, 2015.

[BibTex] [Download]@Article{Schausberger15a, Title = {Optimization-based estimator for the contour and movement of heavy plates in hot rolling}, Author = {Schausberger, F. and Steinboeck, A. and Kugi, A.}, Journal = {Journal of Process Control}, Pages = {23--32}, Volume = {29}, Year = {2015}, Doi = {10.1016/j.jprocont.2015.03.006}, } - F. Schausberger, A. Steinboeck, and A. Kugi, Modellbasierte Optimierung und Regelung der Produktkontur beim Warmwalzen, e & i Elektrotechnik und Informationstechnik, vol. 132, iss. 4–5, p. 221–229, 2015.

[BibTex] [Download]@Article{Schausberger15d, Title = {Modellbasierte Optimierung und Regelung der Produktkontur beim Warmwalzen}, Author = {Schausberger, F. and Steinboeck, A. and Kugi, A.}, Journal = {e {\&} i Elektrotechnik und Informationstechnik}, Pages = {221--229}, Volume = {132}, Year = {2015}, Number = {4--5}, Doi = {10.1007/s00502-015-0309-2}, } - F. Schausberger, A. Steinboeck, A. Kugi, M. Jochum, and D. Wild, Estimation of the thickness asymmetry using models for the contour evolution and vision-based measurements of plates in hot rolling, in Proceedings of METEC and 2nd European Steel Technology and Application Days (ESTAD), Düsseldorf, Germany, 2015.

[BibTex]@InProceedings{Schausberger15b, author = {Schausberger, F. and Steinboeck, Andreas and Kugi, Andreas and Jochum, M. and Wild, D.}, title = {Estimation of the thickness asymmetry using models for the contour evolution and vision-based measurements of plates in hot rolling}, booktitle = {Proceedings of METEC and 2nd European Steel Technology and Application Days (ESTAD)}, year = {2015}, month = {6}, address = {D{\"u}sseldorf, Germany}, } - F. Schausberger, A. Steinboeck, and A. Kugi, Modellierung der Konturentwicklung von Flachprodukten beim Walzen, in Tagungsband GMA-Fachausschuss 1.30 „Modellbildung, Identikation und Simulation in der Automatisierungstechnik“, Anif/Salzburg, Austria, 2013, p. 42–59.

[BibTex]@InProceedings{Schausberger13, author = {F. Schausberger and A. Steinboeck and A. Kugi}, title = {{Modellierung der Konturentwicklung von Flachprodukten beim Walzen}}, booktitle = {Tagungsband GMA-Fachausschuss 1.30 "Modellbildung, Identikation und Simulation in der Automatisierungstechnik"}, year = {2013}, month = {9}, pages = {42--59}, address = {Anif/Salzburg, Austria}, } - F. Schausberger, A. Steinboeck, and Kugi, Feedback Control of the Contour Shape in Heavy-Plate Hot Rolling, IEEE Transactions on Control Systems Technology, vol. 26, iss. 3, p. 842–856, 2018.

[BibTex] [Download]@Article{Schausberger2018, author = {Schausberger, F. and Steinboeck, A. and Kugi}, title = {Feedback Control of the Contour Shape in Heavy-Plate Hot Rolling}, doi = {10.1109/TCST.2017.2695168}, issn = {1063-6536}, number = {3}, pages = {842--856}, volume = {26}, journal = {IEEE Transactions on Control Systems Technology}, year = {2018}, }

Anwendungsbereiche

- Walzwerksautomatisierung

- Kontinuierliche Produktionsprozesse

14.06.2017 Modellierung, Beobachterentwurf und Regelung von kontinuierlichen Brammenwärmöfen

Projektschwerpunkte

- Modellbildung und Parameteridentifikation von kontinuierlichen Wärmöfen

- Beobachterentwurf für nicht messbare Systemgrößen

- Modellbasierte Regelung und Optimierung nichtlinearer dynamischer Systeme

- Nichtlineare modellprädiktive Regelung von Produkttemperaturen

Beschreibung

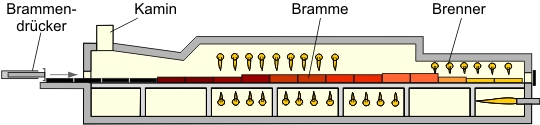

In der Stahlindustrie werden Durchlauföfen zur Erwärmung von Brammen (bis zu 40 Tonnen schwere Stahlblöcke) eingesetzt, ehe diese im nachfolgenden Walzprozess umgeformt werden. Während des energie- und kostenintensiven Erwärmprozesses werden die aneinandergereihten Brammen kontinuierlich durch den gas- oder ölbefeuerten Ofenraum befördert. Der Energieverbrauch eines Brammenwärmofens mittlerer Größe entspricht etwa dem Gesamtenergiebedarf einer Stadt mit 25000 Einwohnern. Die beim Walzen benötigte Materialtemperatur liegt zwischen 1050 und 1200 Grad Celsius und muss aus Qualitätsgründen bei der Erwärmung im Ofen möglichst exakt erreicht werden.

Kontinuierlicher Brammenwärmofen.

Die dem System zugeführte Wärmeenergie wird aus stöchiometrischen Rechnungen des Verbrennungsvorganges ermittelt. Die Wärmeübertragung in die Brammen erfolgt durch Konvektion und vor allem Wärmestrahlung. Basierend auf einer geometrischen Diskretisierung des Ofenraums werden Massen-, Energie- und Strahlungsbilanzen in mathematischen Modellen berücksichtigt. Es handelt sich um ein nichtlineares dynamisches System, das aufgrund der diskontinuierlichen Brammenbewegung schaltenden Charakter aufweist.

Eine heiße Bramme wird aus dem Ofen entnommen, Copyright: Dillinger Hüttenwerke AG.

Basierend auf den echtzeitfähigen mathematischen Modellen schätzen Zustandsbeobachter (z.B. Extended oder Unscented Kalman Filter) die nicht messbare Temperaturverteilung in den Brammen. Mit einem nichtlinearen modellprädiktiven Mehrgrößenregler werden über die Brennstoffzufuhr zu den Brennern die lokalen Ofentemperaturen so einstellt, dass die Temperaturen der Brammen den jeweiligen Produktanforderungen entsprechen und der Energieverbrauch minimiert wird. Eingangs- und Zustandsbeschränkungen sowie stark variierende Brammensolltemperaturen und Brammengeometrien erschweren die Regelungsaufgabe. Hinzu kommt, dass die Reihenfolge der Brammen und deren Drückzeitpunkte von vor- und nachgelagerten Prozessschritten diktiert werden.

Das entwickelte Regelungssystem wird mittlerweile an mehreren industriellen Brammenwärmöfen verwendet. Messungen mit instrumentierten Testbrammen haben gezeigt, dass eine hohe Erwärmgenauigkeit erreicht wird. Das System erzielt gegenüber üblichen Ofenregelungen erhebliche Energieeinsparungen und macht den Prozess durch reduzierten CO2-Ausstoß deutlich umweltfreundlicher.

Ausgewählte Veröffentlichungen

- A. Steinboeck and A. Kugi, Optimized pacing of continuous reheating furnaces, in Proceedings of European Control Conference ECC 2013, Zürich, Switzerland, 2013, p. 4454 – 4459.

[BibTex]@InProceedings{Steinboeck13b, author = {A. Steinboeck and A. Kugi}, title = {{Optimized pacing of continuous reheating furnaces}}, booktitle = {Proceedings of European Control Conference ECC 2013}, year = {2013}, month = {7}, pages = {4454 -- 4459}, url = {http://ieeexplore.ieee.org/xpl/articleDetails.jsp?tp=&arnumber=6669132}, address = {Z\"{u}rich, Switzerland}, } - A. Steinboeck, D. Wild, and A. Kugi, Energy-Efficient Control of Continuous Reheating Furnaces, in Proceedings of 15th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral & Metal Processing, San Diego, USA, 2013, p. 359 – 364.

[BibTex]@InProceedings{Steinbock13, author = {A. Steinboeck and D. Wild and A. Kugi}, title = {{Energy-Efficient Control of Continuous Reheating Furnaces}}, booktitle = {Proceedings of 15th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral \& Metal Processing}, year = {2013}, month = {8}, pages = {359 -- 364}, doi = {10.3182/20130825-4-US-2038.00007}, address = {San Diego, USA}, } - A. Steinboeck, D. Wild, and A. Kugi, Nonlinear model predictive control of a continuous slab reheating furnace, Control Engineering Practice, vol. 21, iss. 4, p. 495–508, 2013.

[BibTex] [Download]@Article{Steinboeck13, Title = {{Nonlinear model predictive control of a continuous slab reheating furnace}}, Author = {A. Steinboeck and D. Wild and A. Kugi}, Journal = {Control Engineering Practice}, Pages = {495--508}, Volume = {21}, Year = {2013}, Number = {4}, Doi = {10.1016/j.conengprac.2012.11.012}, } - A. Steinboeck, D. Wild, and A. Kugi, Optimal Trajectory Planning and Control of a Continuous Slab Reheating Furnace, in Proceedings of the IFAC Workshop on Automation in the Mining, Mineral and Metal Industries, Gifu, Japan, 2012, p. 169 – 174.

[BibTex]@InProceedings{Steinbock12, author = {A. Steinboeck and D. Wild and A. Kugi}, title = {{O}ptimal {T}rajectory {P}lanning and {C}ontrol of a {C}ontinuous {S}lab {R}eheating {F}urnace}, booktitle = {Proceedings of the IFAC Workshop on Automation in the Mining, Mineral and Metal Industries}, year = {2012}, month = {9}, pages = {169 -- 174}, address = {Gifu, Japan}, } - A. Steinboeck, K. Graichen, and A. Kugi, Dynamic Optimization of a Slab Reheating Furnace with consistent Approximation of Control Variables, IEEE Transactions on Control Systems Technology, vol. 19, p. 1444–1456, 2011.

[BibTex] [Download]@Article{Steinboeck11a, Title = {{Dynamic Optimization of a Slab Reheating Furnace with consistent Approximation of Control Variables}}, Author = {A. Steinboeck and K. Graichen and A. Kugi}, Journal = {IEEE Transactions on Control Systems Technology}, Pages = {1444--1456}, Volume = {19}, Year = {2011}, Doi = {10.1109/TCST.2010.2087379}, } - A. Steinboeck, K. Graichen, D. Wild, T. Kiefer, and A. Kugi, Model-based trajectory planning, optimization, and open-loop control of a continuous slab reheating furnace, Journal of Process Control, vol. 21, iss. 2, p. 279–292, 2011.

[BibTex] [Download]@Article{Steinbock11a, Title = {Model-based trajectory planning, optimization, and open-loop control of a continuous slab reheating furnace}, Author = {A. Steinboeck and K. Graichen and D. Wild and T. Kiefer and A. Kugi}, Journal = {Journal of Process Control}, Pages = {279--292}, Volume = {21}, Year = {2011}, Number = {2}, Doi = {10.1016/j.jprocont.2010.08.004}, } - A. Steinboeck, D. Wild, and A. Kugi, Feedback Tracking Control of Continuous Reheating Furnances, in Proceedings of the 18th IFAC World Congress, Milano, Italia, 2011, p. 11744–11749.

[BibTex]@InProceedings{Steinbock11, author = {A. Steinboeck and D. Wild and A. Kugi}, title = {{F}eedback {T}racking {C}ontrol of {C}ontinuous {R}eheating {F}urnances}, booktitle = {Proceedings of the 18th IFAC World Congress}, year = {2011}, month = {8}, pages = {11744--11749}, doi = {10.3182/20110828-6-IT-1002.01639}, address = {Milano, Italia}, } - A. Steinboeck, D. Wild, T. Kiefer, and A. Kugi, A mathematical model of a slab reheating furnace with radiative heat transfer and non-participating gaseous media, International Journal of Heat and Mass Transfer, vol. 53, pp. 5933-5946, 2010.

[BibTex] [Download]@Article{Steinbock10, Title = {A mathematical model of a slab reheating furnace with radiative heat transfer and non-participating gaseous media}, Author = {A. Steinboeck and D. Wild and T. Kiefer and A. Kugi}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {5933-5946}, Volume = {53}, Year = {2010}, Doi = {10.1016/j.ijheatmasstransfer.2010.07.029}, } - D. Wild, T. Meurer, and A. Kugi, Modelling and Experimental Model Validation for a Pusher-type Reheating Furnace, Mathematical and Computer Modelling of Dynamical Systems, vol. 15, iss. 3, p. 209–232, 2009.

[BibTex] [Download]@Article{Wild09, Title = {Modelling and Experimental Model Validation for a Pusher-type Reheating Furnace}, Author = {D. Wild and T. Meurer and A. Kugi}, Journal = {Mathematical and Computer Modelling of Dynamical Systems}, Pages = {209--232}, Volume = {15}, Year = {2009}, Number = {3}, Doi = {10.1080/13873950902927683}, }

Anwendungsbereiche

- Walzwerksautomatisierung

- Industrieöfen

- Kontinuierliche Produktionsprozesse

08.06.2017 MMAssist II

Ziele

Ziel in MMAssist II ist es, das Wesen und die Charakteristik von Assistenz im Produktionskontext grundlegend zu untersuchen, daraufhin optimierte Assistenzsysteme für zukunftsweisende auf Menschen fokussierte Arbeitsplätze („Human-Centered Workplace“) zu entwickeln, diese in industriellen Umgebungen experimentell umzusetzen und zu evaluieren. Die grundlegende Basis für die Umsetzung von Assistenz bilden sogenannte „Assistenz Units“ – Modulare Einheiten, die spezifische Assistenzfunktionalität für die entsprechenden Benutzergruppen bzw. Benutzungsszenarien (multimodal) bereitstellen. Assistenz Units sind so definiert, dass sie über die Use Cases hinweg generalisierbar und wiederverwendbar sind, was einen breiten Impact für die industriellen Partner ermöglicht. Die Implementierung erfolgt durch die Partner als Software Framework, sodass die Basis für eine funktionelle Anwendung gegeben ist.

Die Lösungen werden unter Einbeziehung von MitarbeiterInnen aus produzierenden Unternehmen entwickelt und in weiterer Folge mit den MitarbeiterInnen unter den jeweiligen realen Kontextbedingungen evaluiert werden. Dies bringt Erkenntnisse über die Akzeptanz bzw. dem Benutzererlebnis bei der Verwendung von Assistenzsystemen, und wird damit die Verringerung von Arbeitsbelastung und entsprechende Unterstützungsfunktionalität für die MitarbeiterInnen messbar machen.

Partner

- PROFACTOR (Partner und Koordinator)

- Austrian Institute of Technology

- Evolaris next level GmbH

- Fraunhofer Austria Research GmbH

- JOANNEUM RESEARCH Forschungsgesellschaft mbH

- Paris Lodron Universität Salzburg

- Salzburg Research Forschungsgesellschaft m.b.H.

- Technische Universität Wien, Institut für Automatisierungs- und Regelungstechnik

- VIRTUAL VEHICLE Research Center

- ABF Industrielle Automation GmbH

- AVL List GmbH

- Becom Electronics GmbH

- BRP-Powertrain GmbH & Co KG

- DS AUTOMATION GmbH

- Fronius International GmbH

- Geberit Produktions GmbH

- Kapsch BusinessCom AG

- plasmo Industrietechnik GmbH

- RIC (Regionales Innovations Centrum) GmbH

- Siemens Transformers Austria GmbH & Co KG

- Tablet Solutions

- Tieto Austria GmbH

- TÜV AUSTRIA HOLDING AG

- Wacker Neuson Beteiligungs GmbH

- XiTrust Secure Technologies GmbH

Funding

FFG – Österreichische Forschungsförderungsgesellschaft

08.06.2017 Modellierung und Regelung eines Kühlsystems mit kompaktem Plattenwärmeübertrager

Projektschwerpunkte

- Modellierung der Wärmeübertragung von kompakten Plattenwärmeübertragern

- Physikalisch basierte Modellreduktion

- Nichtlinearer Reglerentwurf basierend auf Leistungsbetrachtungen

Beschreibung

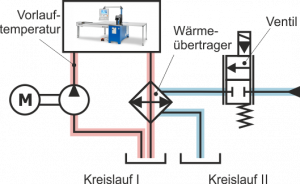

Im Betrieb von Werkzeugmaschinen ist es notwendig, die durch den Prozess zugeführte Wärme gezielt zu kompensieren, um Verzug in der Maschine und damit Fertigungstoleranzen zu reduzieren. Meist wird dabei von Werkzeugmaschinenherstellern gefordert, dass die Vorlauftemperatur der Werkzeugmaschine mit der Umgebungstemperatur mitgeführt wird. Dazu werden häufig Flüssigkeits-Flüssigkeits-Kühlsysteme eingesetzt, die wie in Abb. 1 dargestellt aus zwei Kreisläufen bestehen. Der Primärkreis (I) ist mit der Werkzeugmaschine und der Sekundärkreis (II) mit einer Kühlwasserversorgung verbunden. Als thermische Kopplung werden hier häufig gelötete Plattenwärmeübertrager eingesetzt, da sie bei einer kompakten Bauform gleichzeitig einen sehr hohen Wärmedurchgangskoeffizienten besitzen und günstig zu produzieren sind.

Schematischer Aufbau eines Flüssigkeits-Flüssigkeits-Kühlsystems.

Die Regelungsaufgabe besteht darin, die Vorlauftemperatur der Werkzeugmaschine beliebig vorgeben zu können, indem der Durchfluss des Sekundärkreises mittels eines Proportionalventils geändert wird. Auf die Temperatur der Kühlwasserversorgung kann kein Einfluss genommen werden. Diese wird eingeprägt und bewegt sich in einem kleinen aber unbekannten Bereich. Vernachlässigt man den Wärmeaustausch mit der Umgebung, reduziert sich die Regelungsaufgabe somit zu einer Trajektorienfolgeregelung der Auslauftemperatur des Primärkreises des Wärmeübertragers.

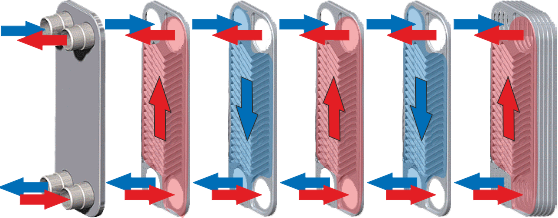

Aufgrund der konvektiven Wärmeübertragung weist das mathematische Modell eines Wärmeübertragers einen verteilt-parametrischen Charakter auf. Des Weiteren ist der Wärmedurchgangskoeffizient, aufgrund der Abhängigkeit der sich ausbildenden thermischen Grenzschichten, nichtlinear abhängig von der Durchflussgeschwindigkeit. Der genaue funktionale Zusammenhang zwischen dem Wärmedurchgangskoeffizienten und den Durchflussgeschwindigkeiten muss dabei durch aufwendige Identifikationen bestimmt werden. Somit stellt sich das mathematische Gesamtmodell eines Plattenwärmeübertragers mit mehreren Kanälen (vgl. Abb. 2) als ein hochdimensionales nichtlineares verteilt-parametrisches System dar.

Kompakt-Plattenwärmeübertrager in Gegenstrombauweise.

Das mathematische Modell eines kompakten Plattenwärmeübertragers kann allerdings aufgrund seines speziellen Aufbaus und der typischen Betriebsbedingungen auf nur zwei gewöhnliche nichtlineare Differentialgleichungen reduziert werden, die eine ausreichende Genauigkeit mit Messungen aufweisen. Des Weiteren kann mit Hilfe einer Leistungsbetrachtung ein Regelgesetz formuliert werden, das unabhängig von dem aufwendig zu parametrisierenden Wärmedurchgangskoeffizienten ist.

Die bisher entwickelten Regelungskonzepte konnten bereits erfolgreich auf einer industriellen Prototypensteuerung implementiert werden.

- A. Michel, Modellbasierte Regelung von industriellen Wärmeübertragern, A. Kugi and K. Schlacher, Eds., Aachen: Shaker Verlag, 2015, vol. 24.

[BibTex]@Book{Michel15, Title = {Modellbasierte Regelung von industriellen W\"arme\"ubertragern}, Author = {Michel, Alexander}, Editor = {A. Kugi and K. Schlacher}, Publisher = {Shaker Verlag}, Year = {2015}, Address = {Aachen}, Series = {Modellierung und Regelung komplexer dynamischer Systeme}, Volume = {24}, ISBN = {978-3-8440-3659-6}, Organization = {Institute f{\"u}r Automatisierungs- und Regelungstechnik (TU Wien) und Regelungstechnik und Prozessautomatisierung (JKU Linz)}, } - A. Michel and A. Kugi, Model based control of compact heat exchangers independent of the heat transfer behavior, Journal of Process Control, vol. 24, p. 286–298, 2014.

[BibTex] [Download]@Article{Michel14, Title = {Model based control of compact heat exchangers independent of the heat transfer behavior}, Author = {Michel, Alexander and Kugi, Andreas}, Journal = {Journal of Process Control}, Pages = {286--298}, Volume = {24}, Year = {2014}, Doi = {10.1016/j.jprocont.2014.02.003}, } - A. Michel and A. Kugi, Accurate low-order dynamic model of a compact plate heat exchanger, International Journal of Heat and Mass Transfer, vol. 61, iss. 33, pp. 323-331, 2013.

[BibTex] [Download]@Article{Michel13, Title = {Accurate low-order dynamic model of a compact plate heat exchanger}, Author = {Michel, A. and Kugi, A.}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {323-331}, Volume = {61}, Year = {2013}, Number = {33}, Doi = {10.1016/j.ijheatmasstransfer.2013.01.072}, } - A. Michel, W. Kemmetmüller, and A. Kugi, Modellierung und Regelung eines Plattenwämetauschers, in Tagungsband GMA-Fachausschuss 1.40 „Theoretische Verfahren der Regelungstechnik“, Anif/Salzburg, Austria, 2010, p. 81–99.

[BibTex]@InProceedings{Michel10, author = {A. Michel and W. Kemmetm{\"u}ller and A. Kugi}, title = {{M}odellierung und {R}egelung eines {P}lattenw{\"a}metauschers}, booktitle = {Tagungsband GMA-Fachausschuss 1.40 "Theoretische Verfahren der Regelungstechnik"}, year = {2010}, month = {9}, pages = {81--99}, address = {Anif/Salzburg, Austria}, }

Anwendungsbereiche

- Regelungsstrategien für Wärmeübertrager

- Prozessautomatisierung

- Automatisierung von Werkzeugmaschinen