Research area Strip Processing

Modeling, observer design, and control of continuous strip processing lines

Research focus

- Modeling and parameter identification of strip processing lines

- Estimation of non-measurable system quantities

- Model-based process control and optimization of distributed parameter systems

- Optimization-based control of system states and product parameters

Steel strip is coated with zinc in a hot-dip galvanizing bath, © voestalpine Stahl GmbH.

Description

As the semi-finished steel strip moves through a continuous strip processing line, it is uncoiled, processed, and again upcoiled. The processing steps may, for instance, include cleaning, descaling, trimming, reheating, annealing, hot-dip galvanizing, cooling, skin passing, tension leveling, surface coating, and surface passivation. Nonlinear control systems for some of these complex production steps are developed in this CD-laboratory in the research area Strip Processing. It deals with model-based control design for laboratory-scale process simulation and materials testing devices, an electromagnetic stabilizing system for moving strip, and a hot-dip galvanizing unit.

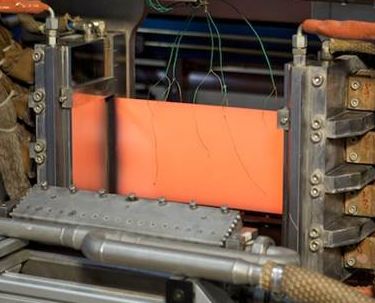

A specimen of steel strip is annealed and quenched in a laboratory-scale test rig, © voestalpine Stahl GmbH.

The operation of an experimental strip annealing furnace with individually controlled infrared heaters constitutes a 2-dimensional in-domain distributed parameter control problem. With the considered test rig, specimens of steel strip should be accurately and uniformly reheated according to predefined temperature trajectories. The devices allow voestalpine to develop and improve new thermal processing strategies for flat steel products. Model reduction techniques as well as advanced state estimation and control methods for distributed parameter systems are developed in this project.

Moreover, an experimental long-term simulation device for build-up defects on strip transport rolls of continuous annealing furnaces is developed. The new test rig facilitates the optimization of process parameters for minimum wear and maximum service live of transport rolls in furnaces. The test rig is modeled as a distributed parameter system for both the temperature and the motion of the strip. Also here, advanced state estimation and control methods tailored to the needs of the distributed parameter system under consideration are applied and further developed.

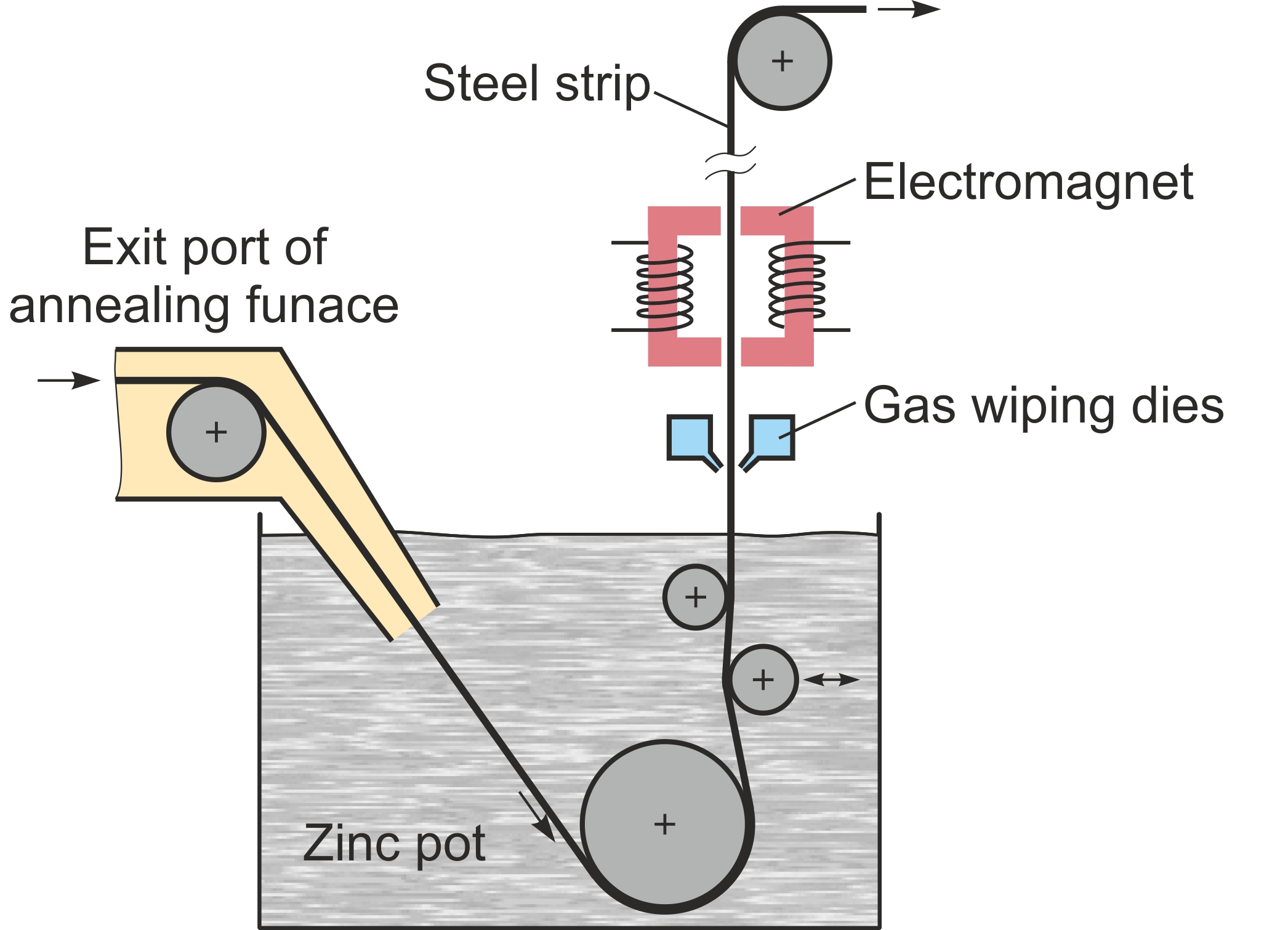

Hot-dip galvanizing unit with electromagnetic strip stabilizer.

For voestalpine, hot-dip galvanizing is an important product finishing step. Hence, the control of this process is also addressed in the research area Strip Processing. For the product quality, it is vital that the zinc coat reliably adheres to the steel surface and that it has an accurate and uniform thickness. However, this thickness cannot be measured for feedback control unless the zinc is fully solidified, which is more than 50 meter after the zinc bath. The time delay of this measurement is a challenge for feedback control. The thickness of the zinc coat is mainly adjusted by gas streams which wipe off excess zinc from the strip surface. For this process, a hierarchical multi-input multi-output (MIMO) control system is developed. The model-based controller also takes into consideration the out-of-plane displacement of the strip, which modulates the effect of the gas streams. Electromagnets are used for non-contact damping of strip oscillations and for compensating crossbow shape defects of the strip. Additional control inputs are the parameters of the gas stream and the position of deflection rolls immersed in the zinc bath. It will be explored whether improved control capabilities allow a redesign of the zinc bath with a reduced number of deflection rolls.

For the control problems solved in this research area, optimization-based approaches like nonlinear model predictive control are often adopted and extended to allow for the distributed parameter character of the systems. Optimization-based control design methods allow for a systematic consideration of input and state constraints, system delays, nonlinear effects, MIMO configurations, and anticipated knowledge of future operating conditions and disturbances.

Links

- Sponsors and research partners

- Related projects at the institute