FESTO Systemlabor

Am 20. Juni 2012 wurde am Institut für Automatisierungs- und Regelungstechnik (ACIN) der TU Wien das Festo Systemlabor eingerichtet. Das von der Gesellschafterfamilie Stoll initiierte und finanzierte Labor widmet sich langfristigen Themen der Grundlagenforschung und angewandten Forschung. Das Institut für Automatisierungs- und Regelungstechnik und die Festo AG vertiefen damit ihre langjährige erfolgreiche Zusammenarbeit auf dem Gebiet der industriellen Bildverarbeitung und der dezentralen Steuerungstechnik.

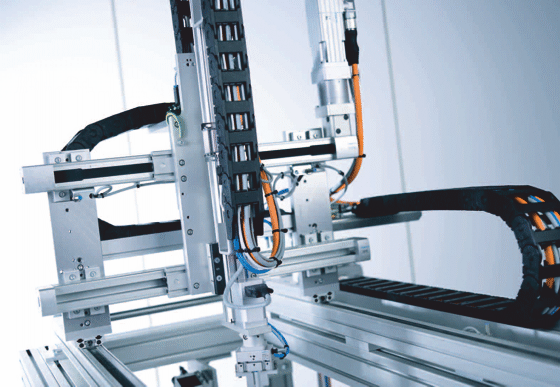

3D-Portalroboter, aufgebaut aus FESTO Systemkomponenten

Seit über 60 Jahren steht die Marke Festo weltweit für Kompetenz in der Fabrik- und Prozessautomatisierung. Festo ist führender Anbieter von pneumatischer und elektrischer Automatisierungstechnik und offeriert zentrale und dezentrale Automatisierungskonzepte für Erzeugung, Transport, Behandlung und Entsorgung von Gasen, Fluiden, pastosen Stoffen oder Schüttgütern.

Mit der Vertiefung dieser Partnerschaft zwischen der Festo AG und dem ACIN sollen die Forschungsthemen um neue methodische Ansätze auf dem Gebiet der optischen Messtechnik mit intelligenten Kameras sowie der mathematischen Modellierung, Analyse und optimalen Regelung elektro-pneumatischer Komponenten und Systeme erweitert werden. Damit sollen in einem interdisziplinären Ansatz neue innovative, nachhaltige und ressourcenschonende Konzepte und Systemlösungen für die Produktionsautomatisierung von morgen erarbeitet werden.

Im Speziellen werden im Forschungsfeld der optischen Messtechnik genauere und schnellere Messmethoden erarbeitet, die eine quantitative Materialcharakterisierung und automatisierte Manipulation von industriellen Gütern erlauben. Im Gebiet der flexiblen Handhabung von biegeschlaffen Materialien werden leistungsfähige modellbasierte Regelungskonzepte zur Aufnahme und zum Ablegen biegeschlaffer Materialien entwickelt. Weiterhin werden durch die Anwendung moderner Regelungs- und Optimierungsmethoden neue Konzepte für servo-pneumatische Linearaktoren unter Verwendung von klassischen Proportionalwegeventilen und von kostengünstigen, schnellschaltenden, elektromagnetischen Ventilen untersucht. Die Entwicklung optimaler Regelungskonzepte für präzise Punkt-zu-Punkt Bewegungen von pneumatischen Linearaktoren unter Zuhilfenahme einer kostengünstigen, örtlich diskreten Wegmessung stellt einen weiteren Schwerpunkt dar. Schließlich werden sogenannte Soft Landing Strategien für elektromagnetische Ventile zur Verlängerung der Lebensdauer und zur Geräuschminimierung entwickelt.

Gemeinsames Ziel der Partnerschaft ist es, die Ergebnisse der universitären Grundlagenforschung in die Industrie zu transferieren und damit die Produktivität und Wettbewerbsfähigkeit von Festo in der Fabrik- und Prozessautomatisierung weiter auszubauen.

Partner

Projekte am Institut

Automatisierte Handhabung biegeschlaffer Materialien

Soft Landing Strategien für elektromagnetische Schnellschaltventile

Component-based Design of Industrial Control Applications Utilizing Formal Methods