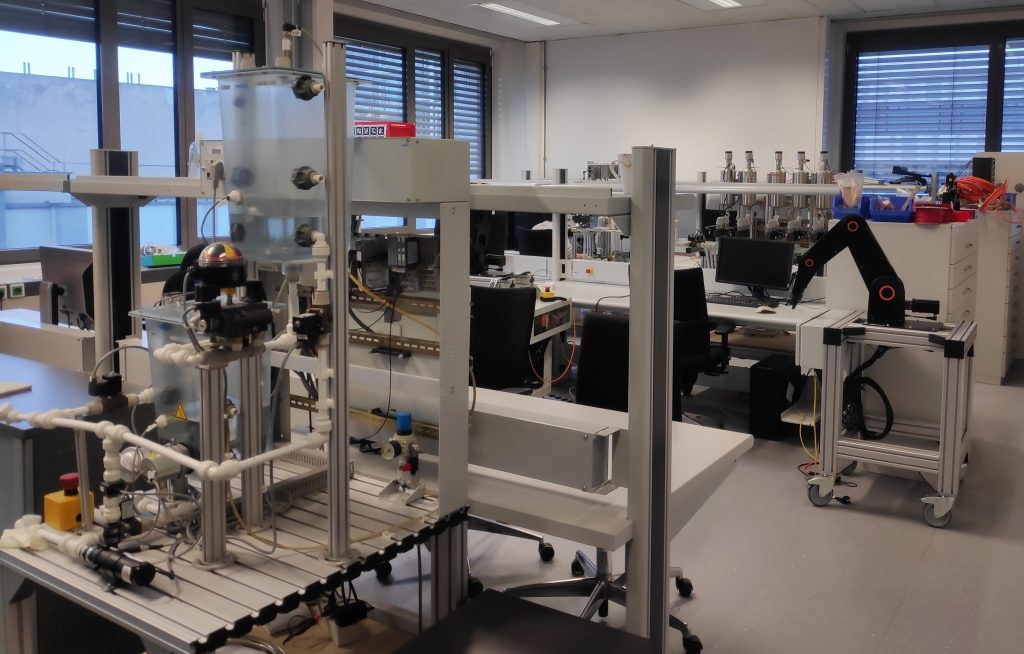

Automation and Robotics – Odo-Struger-Laboratory (OSL)

Equipment

Automation and Robotics – Odo-Struger-Laboratory (OSL)

Research Setups

The following setups are used for research in the fields of robotics and industrial automation.

Research projects on industrial automation, control systems, and robotics

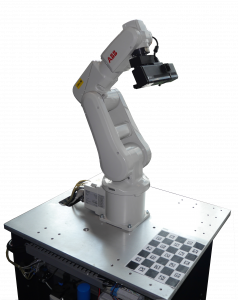

Industrial robots

2x IGUS robolink RL-DP-5

ABB IRB 120

ABB IRB 120

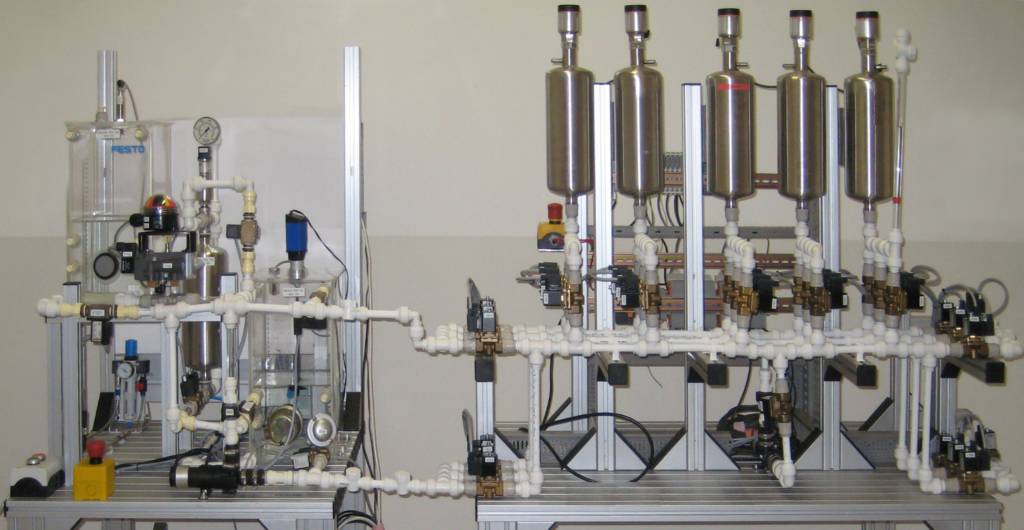

Process engineering setups

Festo Didactic process industry demonstrator plant with two tanks and a custom built storage tank system with five tanks.

Each system has a pump, several valves, and all tanks but one have a level sensor. Additionally, the right tank of the left plant has a heating element and a temperature sensor, as well as an agitator.

Festo Didactic process industry demonstrator plant (left) with two tanks and a custom built storage tank system (right) with five tanks.

Teaching Setups

The following two setups are utilized within the laboratory part of the 376.087 VU Industrial Automation.

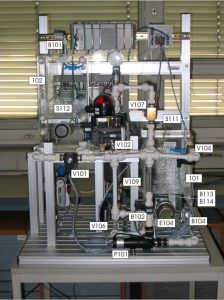

Festo Didactic process industry demonstrator

This setup consists of two tanks, several valves, a pump, various sensors (such as level sensors or flow rate sensors), pipes, and a Rockwell PLC with analog and digital I/O modules.

The plant is utilized to implement process-related recipes with PLCs.

Festo Didactic process industry demonstrator

Resistor Sorter

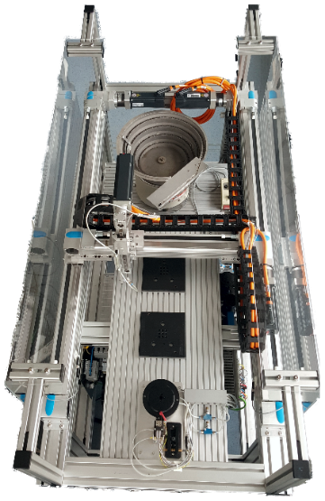

The resistor sorter consists of a portal robot with Beckhoff motors, a vibrating feeder, a resistor measurement station, and a Beckhoff PLC.

This plant is utilized to implement event-driven systems according to the IEC 61499. The intended task is to sort the thermistor platelets based to their resistance into one of the pallets.

Resistor Sorter