Beobachterbasierte iterativ lernende Regelung zur Verbesserung der Bahngenauigkeit von Industrierobotern

Projektfokus

- Modellbildung von nichtlinearen Effekten in Antriebssträngen von Robotern

- Entwurf von hochgenauen, modellbasierten Zustandsbeobachtern

- Iterativ Lernende Regelung zur Verbesserung der Bahngenauigkeit am Endeffektor

Beschreibung

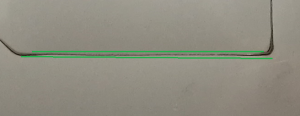

Für Bearbeitungsaufgaben mit Robotern ist die Bahngenauigkeit ein wesentliches Leistungskriterium. Bei vielen Anwendungen sind Genauigkeiten im Bereich von Zehntelmillimeter und darunter gefordert. Beispiele dafür sind das Nahtabdichten von Autokarossen mit Robotern und das Laserschweißen. Bei diesen Anwendungen kommt es nicht nur auf eine hohe statische Genauigkeit an, sondern auf die Gesamtgenauigkeit, bei der auch Schleppfehler der Regelung, sowie dynamische Effekte der Mechanik enthalten sind. In Abbildung 1 wird der Schleppfehler beim Lasermarkieren dargestellt.

Eine wesentliche Ursache für die oben gezeigten Abweichung vom Idealverhalten liegen in den Antriebssträngen. Dabei haben die Getriebe den wichtigsten Einfluss. Gegenüber dem idealen Verhalten weisen Getriebe folgende Abweichungen auf:

- Ungleichmäßige Reibung: durch den variierenden Eingriff der Getriebeverzahnung ist die Reibung stellungsabhängig und lastabhängig.

- Nicht konstantes Übersetzungsverhältnis: durch nicht perfekte Zahnflanken kommt es zu kleinen Schwankungen in der Endeffektorposition. Bei Robotern im Bereich von 1-3 Metern Armlänge kann dies TCP (Tool Center Point)-Fehler im Bereich von einigen Zehntel Millimetern hervorrufen.

- Endliche und variable Steifigkeit: durch die Nachgiebigkeit des Getriebes kommt es in Wechselwirkung mit Reibung und Übersetzungsverhalten zu Schwingungsanregungen. Wenn die Frequenz der variablen Einflussgrößen mit der Resonanzfrequenz der Roboterachse übereinstimmt, kann dies zu massiven dynamischen Fehlern führen.

Die Getriebeeffekte sind vor allem in ihrer dynamischen Wechselwirkung komplex. Messverfahren erfordern meist hochpreisige Messgeräte. Jeder Roboter, für den eine Kompensation eingesetzt werden soll, muss individuell vermessen werden.

Ziel des Projektes ist es, geeignete Robotermodelle und Zustandsbeobachter zu entwickeln, welche die oben beschriebenen Getriebeeffekte beinhalten. Darauf aufbauend sollen neue Regelungsstrategien entworfen werden, mit denen die wachsenden Genauigkeitsanforderungen erreicht werden können. Dabei geht es vor allem auch darum, mechatronische, physikalische Modelle optimal mit der Verarbeitung unstrukturierter Daten zu kombinieren, um eine möglichst hohe Effizienz und einfache Anwendbarkeit zu erreichen. Um weiters auf die Verfügbarkeit von hochgenauen Messsystemen in der Praxis einzugehen, werden kostengünstig verfügbare Sensoren verwendet, um eine breite Anwendbarkeit der entwickelten Methoden zu garantieren. Die so gewonnen Messdaten werden im Zuge einer iterativ lernenden Regelung verwendet, um letztendlich die gewünschte Genauigkeit, nicht nur bei der Positionierung, sondern auch beim Durchfahren von Bahnen zu erreichen.

Ausgewählte Publikationen

- B. Bischof, T. Glück, M. Böck, and A. Kugi, Path Following Control for Elastic Joint Robots, in Proceedings of the 20th IFAC World Congress, Toulouse, France, 2017, p. 4806–4811.

[BibTex]@InProceedings{Bischof17, author = {Bischof, B. and Gl\"uck, T. and B\"ock, M. and Kugi, A.}, title = {Path Following Control for Elastic Joint Robots}, booktitle = {Proceedings of the 20th IFAC World Congress}, year = {2017}, volume = {50}, number = {1}, month = {7}, pages = {4806--4811}, doi = {10.1016/j.ifacol.2017.08.965}, address = {Toulouse, France}, issn = {2405-8963}, } - B. Bischof, Path and Surface Following Control for Industrial Robotic Applications, A. Kugi and K. Schlacher, Eds., Aachen: Shaker Verlag, 2020, vol. 47.

[BibTex]@Book{Bischof2020, author = {Bischof, Bernhard}, title = {{Path and Surface Following Control for Industrial Robotic Applications}}, year = {2020}, editor = {A. Kugi and K. Schlacher}, volume = {47}, series = {Modellierung und Regelung komplexer dynamischer Systeme}, publisher = {Shaker Verlag}, isbn = {978-3-8440-7200-6}, address = {Aachen}, organization = {Institute f{\"u}r Automatisierungs- und Regelungstechnik (TU Wien) und Regelungstechnik und Prozessautomatisierung (JKU Linz)}, }