Reconstruction of workpieces

Research on the reconstruction of workpieces deals with the high-precision reconstruction of three-dimensional free-form surfaces and the extraction of geometric primitives as well as the numerous features and properties of the workpieces. The first step in this process is the reconstruction of the 3D object. The desired object is placed in the working area of the scanning robot and an automatically generated scan trajectory based on the maximum object size or a roughly known object geometry is performed by the robot.

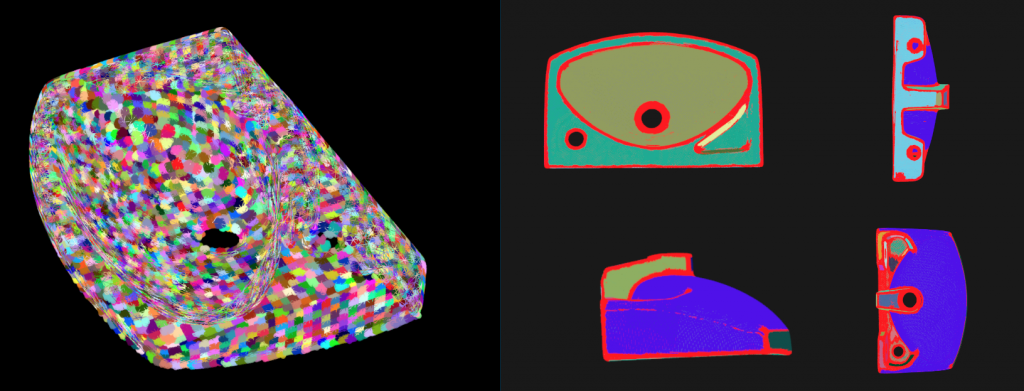

Surface information is extracted in three hierarchical levels, see Fig. 1. At the lowest level, i.e. for each node on the object’s surface, the directions of maximum and minimum curvature towards the neighboring points are determined. These are called the principal axes of curvature. On the middle hierarchical level, the nodes are combined into small areas, the so-called supervoxels. Finally, the object parts are extracted at the highest hierarchical level, i.e. geometric primitives such as planes, cylinder and spherical shapes are recognized.

Supervoxels and geometric primitives.

Furthermore, in the Festo System Laboratory it should be possible to draw conclusions from the demonstrations of surface processes on a small number of objects and apply them to new, previously unseen objects. This is achieved by computing unique features for each point of the demonstration objects and generalizing them to object classes. Correspondences between similar objects can be established using this information, see Fig. 2.

Trajectory generalization.