Path and trajectory planning

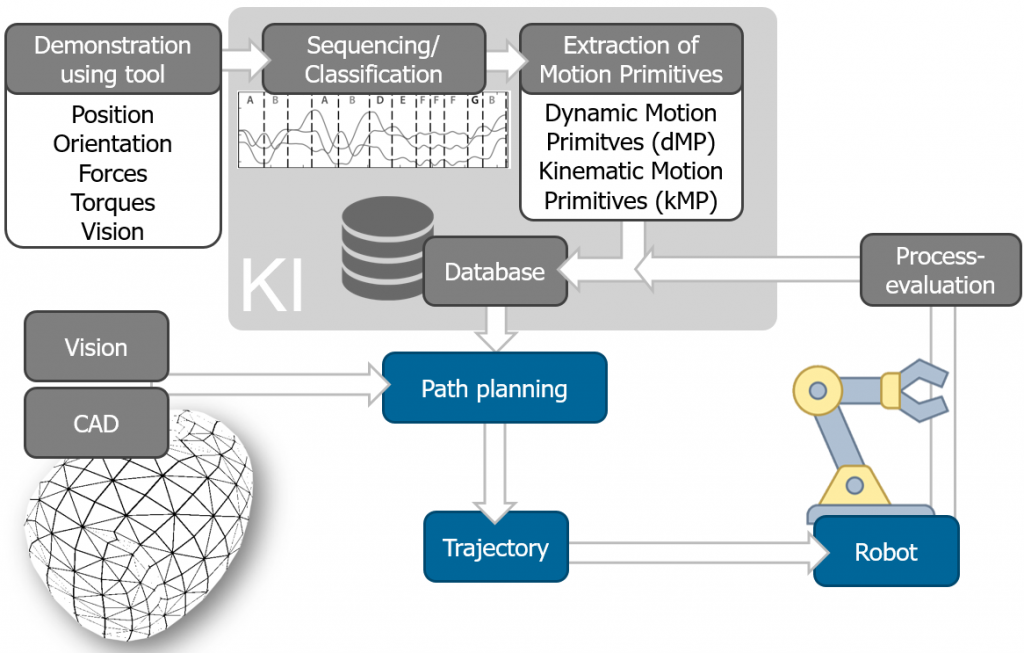

The focus of this research work is the automated and fast trajectory planning under the consideration of the properties of the executed industrial process. The trajectory planning for industrial robots is the interface between the desired Cartesian movements of the robot end-effector and the actual execution on the robot. For the execution of the process and the process evaluation, the desired end-effector movements in the Cartesian space are computed using the process database. These end-effector movements are converted into robot movements with the help of trajectory planning. The robot movements are then executed as desired trajectories in the joint space of the robot using a suitable controller on the robot.

When planning trajectories, the kinematic and dynamic constraints of the robot itself as well as the process constraints must be taken into account. It is not possible to specify an arbitrary end-effector movement in Cartesian space, as this could violate the robot working area, for example. Especially for continuous end-effector movements of the robot, limitations have to be taken into account, such as the mechanical movement ranges of the axes, the limited work space of the robot and the number of degrees of freedom of the robot. Furthermore, collisions with the environment and with the robot itself must be avoided, which is also already taken into account in the robot trajectory planning. Due to these restrictions, it is not always possible to calculate continuous joint space trajectories for the desired movements. However, if the properties of the process and the permitted process tolerances are taken into account, the calculation of complex continuous end-effector paths in the joint space of the robot is possible.