High-speed large format 3D printing

Project focus

- Development of a high speed polygon mirror based SLA 3D-printer

- Opto-mechatronic system design for maximum performance

- Characterization of polygon mirrors

- Correction methods for high resolution printing

Description

Additive manufacturing (AM) constantly gains in importance in the manufacturing industry. Compared to classical manufacturing technologies, it offers many advantages such as almost unlimited design freedom, direct manufacturing of parts from CAD models and affordable manufacturing even at low quantities. Furthermore, parts can be produced with minimum excessive material consumption compared to conventional manufacturing methods. This leads to a significantly reduced ecological footprint of AM. State of the art industrial printers, which achieve high resolution and accuracy, are based on the stereolithography (SLA) principle in combination with Galvanometer beam steering, which scan a laser spot over a resin surface for photopolymerization. Scanning speeds between 2 m/s and 30 m/s are typical and limited by the scanner dynamics, such that medium and large part counts are not economically achievable. By speeding up the manufacturing processes this limitation can be circumvented, enabling additive mass production.

Approach

In order to increase the printing speed and volume without impairing the achievable resolution, an integrated opto-mechatronic system design is applied in this project. In the development of the optical scanning unit, not only conventional galvanometer scanners, but also other scanners such as fast steering mirrors and polygon scanners will be considered. Such components will be synthesized to complement each other, where their interaction will be explicitly considered. Control algorithms of the synthesized system will be selected and designed by considering the underlying physical phenomena, such as mechanical dynamics and photochemical dynamics for the highest possible performance.

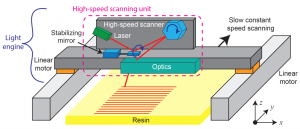

Schematic setup of the polygon mirror based SLA 3D-printer. The light engine, which consists out of a laser stabilizing mirror and the polygon scanner, is moved by two linear motors.[/caption]

Schematic setup of the polygon mirror based SLA 3D-printer. The light engine, which consists out of a laser stabilizing mirror and the polygon scanner, is moved by two linear motors.[/caption]

Videos

Project Partners

Funding

Ansprechpartner

Dipl.-Ing. Johannes SchlarpUniv.-Prof. Dipl.-Ing. Dr.sc.techn. Georg Schitter

ProjektmitarbeiterInnen

MSc Bo CongDipl.-Ing. Johannes Schlarp

MAS, Dr.techn. Shingo Ito

Daniel Pechgraber

Thomas Scherzer