Noreia

Project focus

- Development and Construction of highly sophisticated PVD deposition plant

- Highly flexible and recipe based programming method for reproducible lot size one hard coatings

- Component-based design and programming approaches for modular plant construction

Description

Project Noreia entitles the design and development of a highly sophisticated PVD deposition plant, which consider state of the art developments in automation and control as well as deposition techniques. The design and development is conducted in a framework between the Institute of Materials Science and Technology (Prof. Paul H. Mayrhofer) and the Faculty of Electrical Engineering and Information Technology within the TU Wien.

The aim of the cutting-edge concept is to connect the advantages of industrial deposition plants and labor scale systems to provide an ideal setup for application oriented coating development. Industrial processes are always qualified through high deposition rates and optimal target erosion which is strongly linked to enhanced target power densities and at least larger target geometries. Labor scale deposition systems protrude through Ultra High Vacuum (UHV) conditions and a huge variety in process controlling as well as individual target powering and positing to deposit most diverse coating architectures. Noreia combines all these aspects within one system.

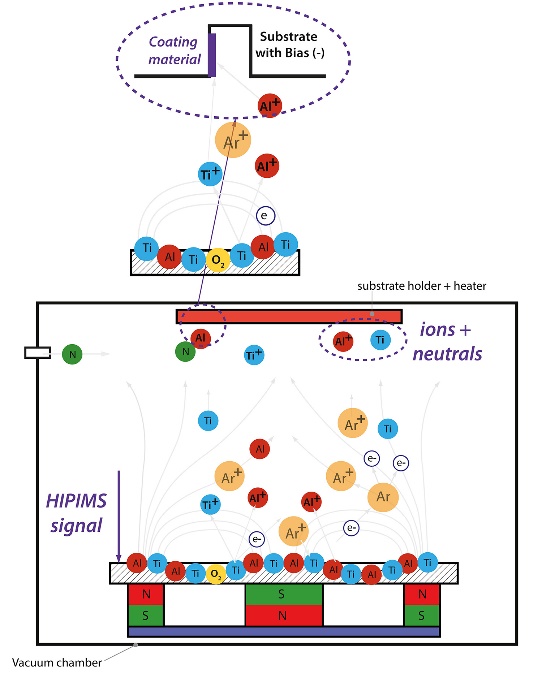

Deposition process

In addition, Noreia is equipped with state of the art magnetron systems powered by High Power Impulse Magnetron Sputter (HiPIMS) generators to combine the advantageous of DC magnetron sputtering and arc-evaporation without their drawbacks of shadowing effects and macro particles. A load lock system gives the possibilities for an easy substrate exchange as well as UHV conditions. To precisely influence the deposition parameters such as bias voltage or substrate temperature and hence film properties, Noreia is provided with an innovative substrate heating and powering system to control nucleation and film growth.

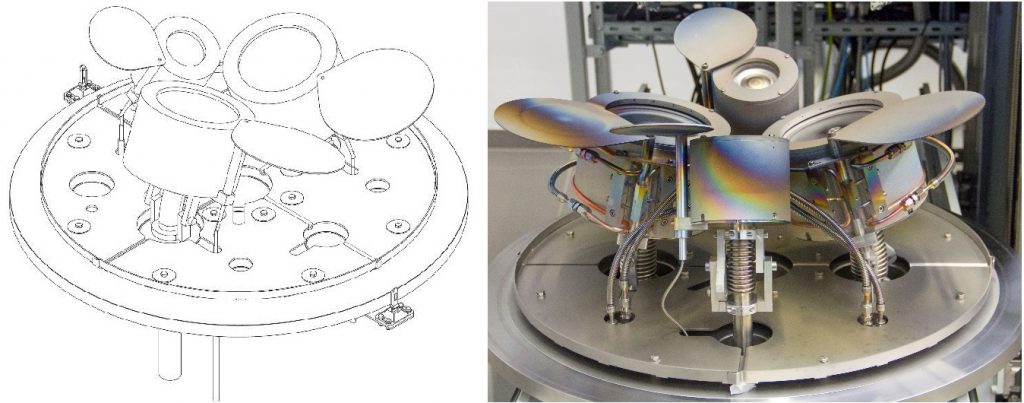

Cathode array

All deposition parameters such as target powering, substrate heating, gas flow, pressure control, cooling system, etc. are controlled through a Programmable Logic Controller (PLC) to provide the user highest possible comfort in usage as well as a highest freedom to influence the deposition process.

Left: money clips with titan-nitride coating (golden TU/Noreia text). Right: burning plasma in a nitrogen/argon

Application areas

- Component-based automation systems

- Flexible manufacturing systems

Related publications

- M. Melik-Merkumians, M. Baierling, and G. Schitter, A Service-Oriented Domain Specific Language Programming Approach for Batch Processes, in Proceedings of 2016 IEEE 21th Conference on Emerging Technologies & Factory Automation, 2016.

[BibTex]@InProceedings{TUW-251132, Title = {A Service-Oriented Domain Specific Language Programming Approach for Batch Processes}, Author = {Melik-Merkumians, Martin and Baierling, Matthias and Schitter, Georg}, Booktitle = {Proceedings of 2016 IEEE 21th Conference on Emerging Technologies {\&} Factory Automation}, Year = {2016}, Note = {Vortrag: 21st IEEE International Conference on Emerging Technologies and Factory Automation (ETFA 2016), Berlin; 2016-09-06 -- 2016-09-09}, Doi = {10.1109/ETFA.2016.7733729}, Eid = {68}, ISBN = {978-1-5090-1314-2}, Keywords = {SOA, DSL, Batch Process, ISA-88, IEC 61499, component based automation, service based automation}, Numpages = {9} }

Project partners

- Project leader: TU Wien – Prof. Paul Heinz Mayrhofer

- Pfeiffer Vacuum Austria GmbH

- GSA Elektrotechnik und Engineering GmbH

- Beckhoff Automation GmbH

- MKS Instruments Deutschland GmbH

- Gencoa Ltd

- SMC Pneumatic GmH

- VAT Vakuumventile AG

- Advanced Energy Industries

Ansprechpartner

Dipl.-Ing. Martin Melik-MerkumiansUniv.-Prof. Dipl.-Ing. Dr.sc.techn. Georg Schitter

ProjektmitarbeiterInnen

Dipl.-Ing. Martin Melik-MerkumiansIng. Philipp Ertelthaler

Dipl.-Ing. Dr.techn. Helmut Riedl

Thomas Scheu

Stefan Risslegger

Jovica Bozic