13.06.2024 HiFliTE

Humanoid robots are designed to mimic humans’ physical appearance and intricate movements. The quest for creating humanoid robots with human-like motion capabilities represents a fundamental milestone in robotics. On one side, researchers focus on providing robots with the same ability as humans to perform multiple tasks simultaneously. On the other hand, researchers focus on designing dynamic controllers that enable humanoid robots to run or jump at different elevations, improving their mobility in unstructured environments.

In this context, the HiFliTE project aims at making two-legged robots able to perform tasks not feasible for the robot structure (e.g., because of height, joint position limits, lack of limbs) by exploiting the flight phase of a jump. To achieve this goal, a high-level control framework will be designed to plan the motion during the phases of take-off, flight, and landing. During the flight phase, the goal will be controlling one end-effector of the robot to perform a defined task while the rest of the body compensates for the end-effector motion and stabilizes the robot. This framework will be validated on a bipedal robot that is not equipped with arms to perform the task of opening the door. Since the robot has no arms, during the flight phase, one leg will be controlled to kick on the door handle/panic bar, and the other one and the torso to compensate for the motion.

Funding

ÖWA and FWF

01.06.2024 HängMan

The HängMan project aims at a novel technical solution for maintenance and in-contact inspection of large-scale infrastructure and industrial facilities, which require an operation in hardly accessible areas in large height. While unmanned aerial vehicles are already in use for the contactless inspection tasks, there exists no widely applicable solution for manipulation tasks, which require a direct physical interaction in contact. The envisioned system consists of a motorized base unit equipped with propellers and a manipulator arm. The base is carried and roughly put in place at the required task location by an external crane system. Compared to conventional aerial systems, the proposed system can carry much higher loads and is able to exert high external forces onto the environment. The on-board propellers are utilized for stabilizing the undesired oscillation of the supported base and for fine positioning the system, while interaction forces due to the motion and manipulation of the manipulator are compensated. In the project, we will integrate a prototype of the system and evaluate the performance for precise positioning as well as for manipulation of the environment. Moreover, also the influence of external disturbances, such as wind, on the accuracy of the system shall be analyzed. The system will finally be tested in two example applications for inspection and maintenance. Possible application areas of the envisioned system lie in the maintenance, inspection, and repair of large-scale facilities in the oil and gas industry, the maintenance of windmills, bridge pillars, buildings, solar collectors, as well as in the maintenance of large-scale infrastructure of the energy sector. These applications require the use of well-trained personnel, such as industrial climbers, and therefore have high cost and time requirements.

Funding

The Austrian Research Promotion Agency (FFG)

14.03.2023 ERC NatDyReL (Utilizing Natural Dynamics for Reliable Legged Locomotion)

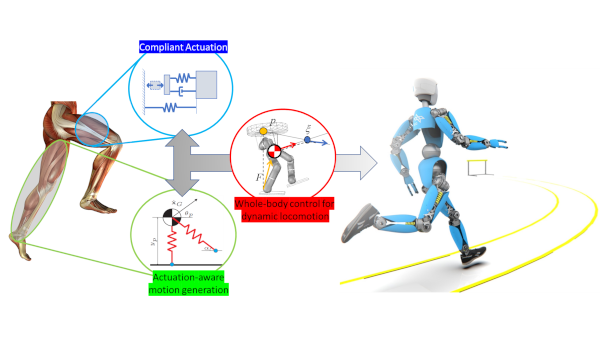

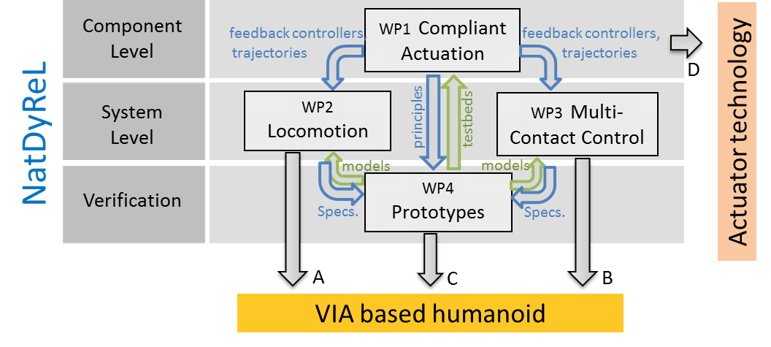

The NatDyReL (Utilizing Natural Dynamics for Reliable Legged Locomotion) project aims at a fundamental paradigm shift in the design and control of humanoid robots. This paves the way for a new generation of intrinsically compliant robots that are capable of adjusting their open loop actuator impedance in real-time to the task. Most importantly, the developed methods will allow for their use and adaptation in other morphologies, including multi-limbed walking or climbing robots.

Concept

In contrast to the now mature technology of torque-controlled drives, the robot developed in NatDyReL will be based on highly compliant actuators. This technology has the strong potential to enable physical robustness against external impacts and allows for periodic energy storage and release during highly dynamic motions. The robot will be able to adapt its dynamic behaviour at runtime to the current ground conditions and to the desired walking speed. In addition, part of the kinetic energy can be temporarily stored in the elastic drives at each step, thus enabling robust and energy-efficient execution of dynamic walking movements. In order to successfully implement these concepts in practice, it is necessary to take the actuator dynamics fully into account in the planning of the overall body movement as well as in the real-time control. Considerable effort thus will be spent on the fusion of whole-body locomotion algorithms with novel concepts for the control of elastic actuators. The project requires close interdisciplinary cooperation between experts from different disciplines, especially from robotics, control engineering and mechatronics.

Intermediate Results

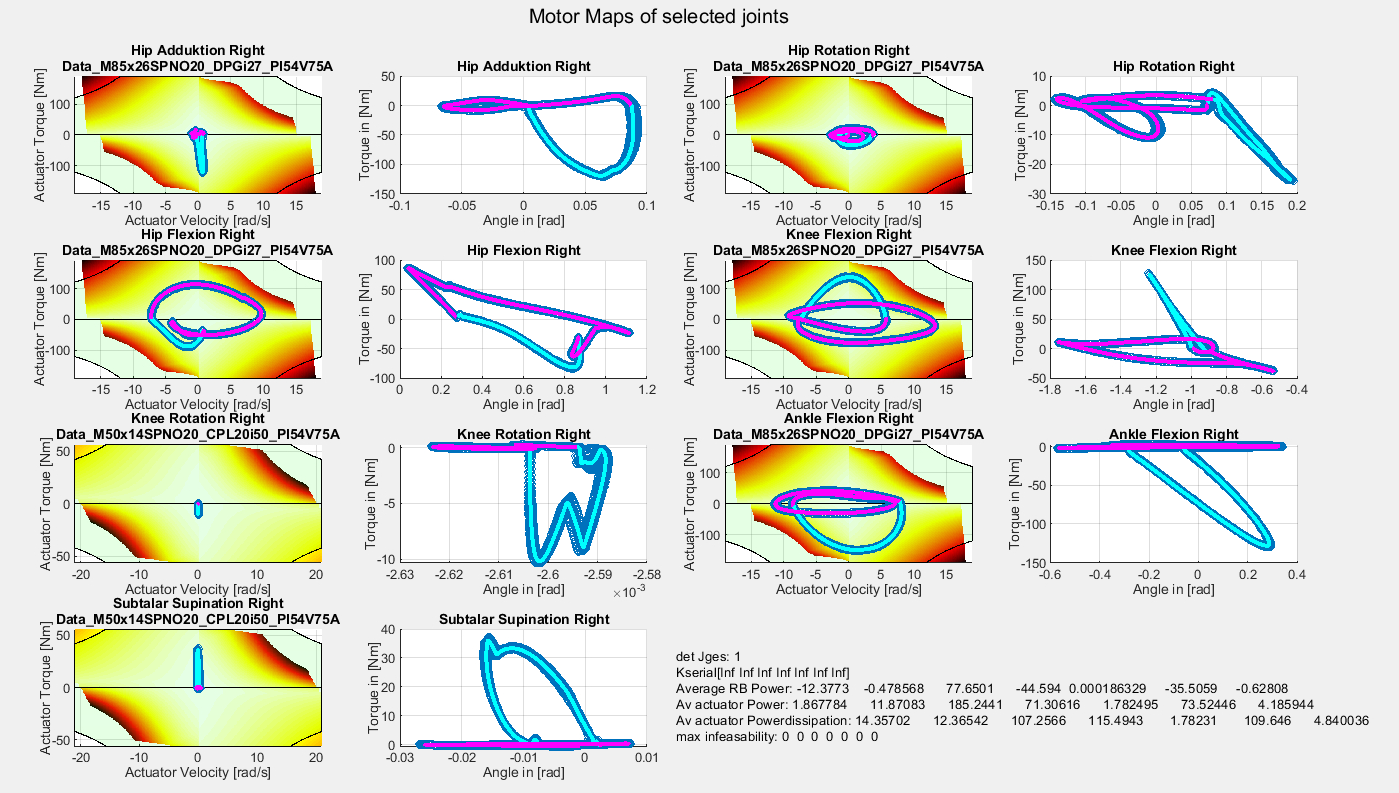

The simulation of the NatDyReL robot running at a speed of 4 m/s. The running motions were generated based on a passivity-based whole-body controller which integrates the desired contact forces according to the Biologically inspired dead-beat (BID) running control framework.

In this simulation, the robot is running at 3 m/s. The gait is optimized for minimal motor power consumption

The resulting motor speeds and torques of the joints at the leg are optimized within the feasible area (light green colored zone).

Key Research Questions

With the research performed in the four work-packages we aim to answer the following fundamental scientific questions:

- How to design energy efficient gaits and high performant whole body motions for highly compliant legged robots? [WP2]

- How to realize dynamic contact transitions in multi-contact locomotion? [WP3]

- How to stabilize all these motions by feedback control in a robust way? [WP2-3]

- How to adapt the intrinsic impedance characteristics to uncertainties or variability in the body dynamics and the environment? [WP2]

- How to design the body structure and actuation system of humanoid robots in order to balance the requirements on energy efficiency, robustness, and performance in terms of speed? [WP4]

Project structure

WP1: Fundamentals for robot control with variable impedance actuators

- Development of a generic framework to control a large family of elastic actuators

- Preservation of the intrinsic elastic dynamics in the feedback control

- Control of elastic actuators under strong joint couplings

WP2: Efficient Legged Locomotion

- Generation of dynamic trajectories for locomotion by utilization of the intrinsic elastic robot dynamics

- Optimization and adaptation for energy efficiency in cyclic locomotion

- Generation of high-performance acyclic motions

- Versatile locomotion in uncertain terrain

- Enforcing a tight interaction between the whole-body locomotion framework and the actuator control

WP3: Multi-Contact Control

- Multi-contact planning with impacts and variable contact timing

- Reactive control for Loco-Manipulation

WP4: Prototype development

- Design of an elastic biped as the main demonstrator

- Benchmarking

Partners

- TU Wien (Coordinator)

- Institut of Robotics and Mechatronics, German Aerospace Center (DLR e.V.)

Funding

Consolidator Research Grant of the European Research Council (ERC).

10.03.2023 Control of Motional Quantum States for Levitated Particles

Project focus

- Feedback cooling of levitated nanoparticles into its quantum ground state

- Generation of more evolved motional quantum states, e.g., quantum squeezed states and non-gaussian states

- High-performance real-time control using FPGAs

- Shaping of optical trapping potentials

- Quantum-enhanced sensing applications

Description

Over the past decade, great progress in the engineering of optomechanical platforms has pushed nano- and micro-meter-sized objects into the realm where quantum effects start to manifest themselves. Recently, platforms based on the optical levitation of particles have emerged that offer superior isolation from their environment while benefitting from the flexibility and tunability of all-optical manipulation. These experiments combine established methods from optomechanics with strategies from atomic physics, matterwave interferometry, and control theory to explore macroscopic quantum physics. Along with their unrivaled sensitivity, levitated nanoparticles hold promises ranging from commercial sensing applications to the search for new physics.

In this research project, we aim to utilize methods from control theory to develop real-time-capable control algorithms in order to generate motional quantum states of the levitated particle. To this end, cooling the center-of-mass of the particle through measurement feedback is a crucial first step, which is possible by combining Heisenberg-limited measurements with optimal stochastic control concepts. This opens the door to more envolved quantum states such as squeezed states, which provide opportunities with respect to quantum-enhanced sensing applications as well as coherent state expansion, and ultimately non-gaussian states by letting the particle evolve in a nonlinear potential.

Selected publications

- L. Magrini, P. Rosenzweig, C. Bach, A. Deutschmann-Olek, S. G. Hofer, S. Hong, N. Kiesel, A. Kugi, and M. Aspelmeyer, Real-time optimal quantum control of mechanical motion at room temperature, Nature, vol. 595, p. 373–377, 2021.

[BibTex] [Download]@Article{magrini2021, author = {L. Magrini and P. Rosenzweig and C. Bach and A. {Deutschmann-Olek} and S. G. Hofer and S. Hong and N. Kiesel and A. Kugi and M. Aspelmeyer}, title = {Real-time optimal quantum control of mechanical motion at room temperature}, doi = {10.1038/s41586-021-03602-3}, pages = {373--377}, volume = {595}, journal = {Nature}, year = {2021}, }

Partners

Funding

This project is funded by the Austrian Science Fund [PAT 9140723] and the European Union – NextGenerationEU.

10.03.2023 Control strategies for quantum fields

Project focus

- precise optical potentials for ultra-cold clouds of atoms through iterative control algorithms

- optimal (quantum) thermodynamic operations of the quantum gas

- controlled splitting of atom clouds to generate spin-squeezed or entangled states

Description

Some of the most intriguing problems in physics, ranging from the early universe to quantum materials, are linked to the dynamics of large ensembles of interacting particles exhibiting genuine quantum behavior. These quantum many-body problems and their description in terms of quantum field theory are often hard or impossible to simulate in their full complexity on even the fastest classical computers. To circumvent this problem, so-called quantum simulators became a very active field of research over the last decade. Similar to analog computers, quantum simulation aims at building highly configurable experiments to reproduce the desired physics behind quantum many-body systems with these model systems. One central aspect when utilizing such model systems as quantum simulators is how to control the model system to perform the desired simulation, i.e., how to prepare the initial states and how to mirror the desired simulation target with the experimentally available model. Thereby, trapped clouds of ultra-cold atoms are ideal model systems that are flexible and sufficiently mature to be routinely generated in labs around the world.

The key motivation of this project is to develop control algorithms that enable such operations with sufficient precision for ultra-cold atom experiments. As such we aim at developing tools for two distinct physical situations: First, to control the quantum fields in small thermal machines that can be generated by splitting the atom cloud into several compartments. Such experiments would help to investigate thermodynamic properties of many-body systems in the quantum regime. At the heart of this newly developing field of quantum thermodynamics lies the question on whether or how excitations of an isolated quantum many-body system relax such as classical many-body systems eventually do. These questions ultimately continue the long-standing discussion on the relation between the microscopic and the macroscopic world. Second, we aim at exploring and developing algorithms to optimize the splitting of a single atomic cloud into two. Describing this splitting process in full detail is beyond computational capabilities. Thus, pre-calculated protocols to achieve splitting of the cloud typically yield unsatisfying results. However, we conjecture that the combination of existing simplified models and measurement information is sufficient to iteratively learn and refine control trajectories. This would allow us to prepare desired quantum states of the split cloud that are essential for many quantum field and quantum metrology experiments.

Partners

Research group “Atom physics and quantum optics” (Jörg Schmiedmayer)

Selected Publications

- A. Deutschmann-Olek, K. Schrom, N. Würkner, J. Schmiedmayer, S. Erne, and A. Kugi, Optimal control of quasi-1D Bose gases in optical box potentials, in Proceedings of the 22nd IFAC World Congress, Yokohama, Japan, 2023 2023, pp. 1339-1344.

[BibTex]@InProceedings{DeutschmannOlek2023a, author = {Deutschmann-Olek, A. and Schrom, K. and W\"urkner, N. and Schmiedmayer, J. and Erne, S. and A. Kugi}, booktitle = {Proceedings of the 22nd IFAC World Congress}, date = {2023}, title = {Optimal control of quasi-1D Bose gases in optical box potentials}, doi = {10.1016/j.ifacol.2023.10.1781}, number = {2}, pages = {1339-1344}, volume = {56}, address = {Yokohama, Japan}, issue = {2}, journaltitle = {IFAC-PapersOnLine}, month = {7}, year = {2023}, } - M. Calzavara, Y. Kuriatnikov, A. Deutschmann-Olek, F. Motzoi, S. Erne, A. Kugi, T. Calarco, J. Schmiedmayer, and M. Prüfer, Optimizing Optical Potentials With Physics-Inspired Learning Algorithms, Physical Review Applied, vol. 19, iss. 4, p. 44090, 2023.

[BibTex]@Article{Calzavara2023, author = {Calzavara, M. and Kuriatnikov, Y. and Deutschmann-Olek, A. and Motzoi, F. and Erne, S. and Kugi, A. and Calarco, T. and Schmiedmayer, J. and Pr\"ufer, M.}, title = {Optimizing Optical Potentials With Physics-Inspired Learning Algorithms}, doi = {10.1103/physrevapplied.19.044090}, number = {4}, pages = {044090}, volume = {19}, journal = {Physical Review Applied}, publisher = {American Physical Society (APS)}, year = {2023}, } - A. Deutschmann-Olek, M. Tajik, M. Calzavara, J. Schmiedmayer, T. Calarco, and A. Kugi, Iterative shaping of optical potentials for one-dimensional Bose-Einstein condensates, in Proceedings of the 61st Conference on Decision and Control (CDC), Cancun, Mexico, 2022, p. 5801–5806.

[BibTex]@InProceedings{DeutschmannOlek2022, author = {Deutschmann-Olek, Andreas and Tajik, Mohammadamin and Calzavara, Martino and Schmiedmayer, J\"org and Calarco, Tommaso and Kugi, Andreas}, booktitle = {Proceedings of the 61st Conference on Decision and Control (CDC)}, title = {Iterative shaping of optical potentials for one-dimensional Bose-Einstein condensates}, doi = {10.1109/CDC51059.2022.9993271}, pages = {5801--5806}, address = {Cancun, Mexico}, month = {12}, year = {2022}, }

Funding

This project is funded by the Austrian Science Fund (FWF) [P36236] and the European Union – NextGenerationEU.

21.10.2022 Recycling Heroes

26.09.2022 Modeling, observer design, and control of continuous casting processes

26.09.2022 Modeling, observer design, and control of material properties in strip processing lines

26.09.2022 Modeling, observer design, and control of the coating weight and surface quality in hot-dip galvanizing lines for steel strips

29.08.2022 Optimization of start times and product sequences in a multi-line hot rolling mill

Project focus

- Modelling of the processing times of products

- Computation of optimal product start times with deterministic and stochastic processing times

- Optimization of the sequence of products

Description

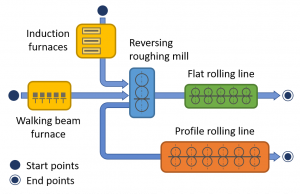

In a multi-line rolling mill for stainless steel, sectional and flat bars as well as wire are produced. The products have different production parameters (steel grades, cross-sections, rolling temperatures, rolling speeds, etc.). Figure 1 shows an outline of the considered plant. In the first processing step, the products are reheated to specific rolling temperatures. Most of them are heated in a walking beam furnace and only a few are heated in induction furnaces. In the next step, the hot products are rolled out to an intermediate square cross-section by a reversing roughing mill. Afterwards, the intermediate products are processed to steel bars or wire in the profile rolling line or to flat steel in the flat rolling line.

Scheme of the multi-line rolling mill.

At the profile rolling line, see Fig. 2, tool changes are required when the dimensions of the product cross section change. During these tool changes, products are manufactured at the flat rolling line. The following points are important for the throughput and efficiency of the plant:

- Considering all safety-relevant time buffers, the start times of the products should be chosen to minimize the time intervals between successive products. This strategy maximizes the product throughput.

- The product sequence has to be chosen so that retooling times entailed by different product parameters of successive products are minimized.

- During tool changes at the profile rolling line, the products processed at the flat rolling line should be chosen so that their total production time optimally fills the time span of the tool changes. This total production time depends also on the rolling sequence of the chosen products at the flat rolling line.

Section of the profile rolling line.

As a basis for optimizing the start times, models of the processing times of products are developed for all relevant sections of the plant. These models can predict the processing of all products in the form of discrete-event times at which products pass defined points along the line. The optimal start time of a product is then determined based on the event times of the previous product and displayed to the operators on a terminal.

The optimization problem of selecting and sequencing the products is known to be NP-hard. To approximately solve this problem, various heuristic algorithms (local search, simulated annealing, tabu search) are implemented and analyzed. Furthermore, the application of methods to determine exact solutions (branch and bound, constraint programming optimization) is studied, at least to find optimal sequences for subsets of products. The optimized selection and sequence of products minimize unproductive retooling and setup times and thus maximize the product throughput of the plant.

Selected publications

- M. Kowalski, A. Steinboeck, A. Aschauer, and A. Kugi, Optimal Start Times for a Flow Shop with Blocking Constraints, No-Wait Constraints, and Stochastic Processing Times, in Proceedings of the 17th IFAC Symposium on Information Control Problems in Manufacturing INCOM 2021, Budapest, Hungary, 2021, pp. 659-664.

[BibTex]@InProceedings{Kowalski2021, author = {M. Kowalski and A. Steinboeck and A. Aschauer and A. Kugi}, booktitle = {Proceedings of the 17th IFAC Symposium on Information Control Problems in Manufacturing INCOM 2021}, title = {Optimal Start Times for a Flow Shop with Blocking Constraints, No-Wait Constraints, and Stochastic Processing Times}, doi = {10.1016/j.ifacol.2021.08.176}, note = {17th IFAC Symposium on Information Control Problems in Manufacturing INCOM 2021}, number = {1}, pages = {659-664}, url = {https://www.sciencedirect.com/science/article/pii/S2405896321009460}, volume = {54}, address = {Budapest, Hungary}, issn = {2405-8963}, journal = {IFAC-PapersOnLine}, year = {2021}, }

- M. Kowalski, A. Steinboeck, and A. Kugi, Scheduling Multiple Groups of Jobs for a Multi-Line Steel Hot Rolling Mill, in Proceedings of the 19th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing MMM, Montreal, Canada, 2022, p. 168–173.

[BibTex]@InProceedings{Kowalski2022, author = {M. Kowalski and A. Steinboeck and A. Kugi}, booktitle = {Proceedings of the 19th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing MMM}, title = {Scheduling Multiple Groups of Jobs for a Multi-Line Steel Hot Rolling Mill}, doi = {10.1016/j.ifacol.2022.09.262}, note = {IFAC-PapersOnLine}, number = {21}, pages = {168--173}, volume = {55}, address = {Montreal, Canada}, month = {08}, year = {2022}, }

Applications

- Automation of rolling mills

- Optimization of processing times and product sequences in production processes