07.01.2022 Fast trajectory planning for robotic systems in the presence of obstacles and dynamically moving targets

Project focus

- Fast planning and replanning of trajectories

- Obstacle avoidance, moving targets

- MPC-based trajectory tracking control

Description

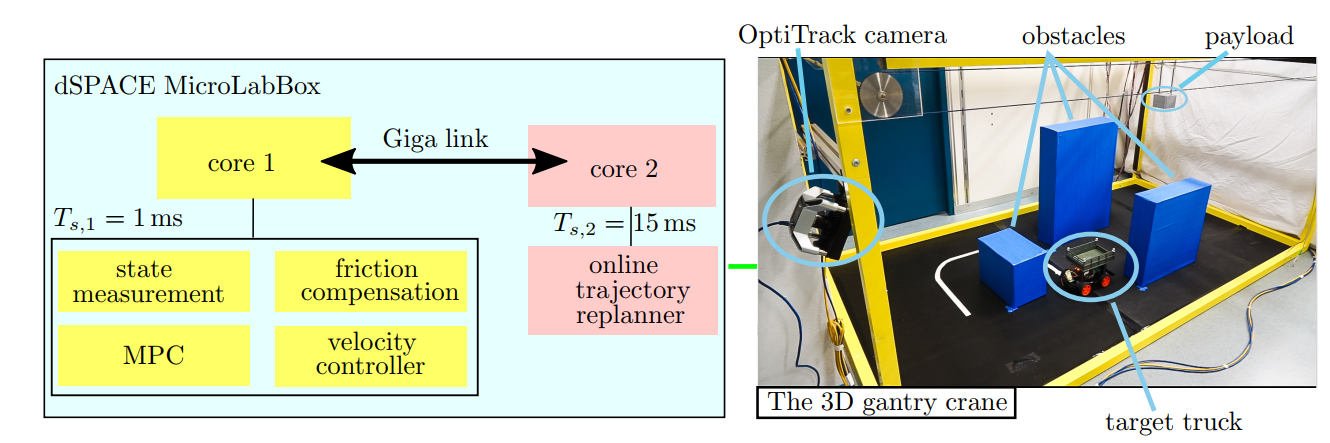

This research work addresses the development of new methods for fast path planning in presence of obstacles and moving targets.This is an important topic for various applications in the field of robotics, handling systems and construction machines such as cranes or collaborative robots. Fig. 1 shows the lab-sized experimental setup of the 3D gantry crane. The task is to implement a fast algorithm to re-plan the trajectories for a payload to reach the moving truck while avoiding obstacles.

Fig. 1: System overview and experimental setup of the 3D gantry crane

Description

In this research, fast optimization-based trajectory planning algorithms are investigated and implemented in both simulation and experiment. Since optimization of trajectory planning usually takes a long time, it is reasonable to use the suboptimal solutions as the initial guess trajectory then refine the overall solution through iterations. In addition, the proposed algorithm should be able to generate a new trajectory when the target configuration changes by using previously computed suboptimal solutions from a database. In addition, fast trajectory planning must be executed at any time, i.e., the algorithms can be interrupted at any time, but will always lead to reasonable, albeit suboptimal, results. This is an important requirement for the real-time capability of the proposed algorithms.

The focus of this project lies on the efficient trajectory (re)planning, which consists of two steps:

- First, an offline trajectory planner is implemented to setup a time-optimal, collision-free, and dynamically feasible trajectory database that connects all the starting points from a predefined starting subspace to all target points in a target subspace.

- Second, based on linear constrained quadratic programming, the online trajectory replanner utilizes the offline trajectory database to generate an optimal trajectory in real time that accounts for all changes in the target state.

Additionally, a trajectory tracking controller is developed to take into account the dynamic constraints for the gantry crane and to compensate for the possible influence of model inaccuracies, disturbances, and other non-modeled effects.

Video

Selected publications

- M. N. Vu, P. Zips, A. Lobe, F. Beck, W. Kemmetmüller, and A. Kugi, Fast motion planning for a laboratory 3D gantry crane in the presence of obstacles, in Proceedings of the 21st IFAC World Congress, Berlin, Germany, 2020, p. 9508–9514.

[BibTex]@InProceedings{Vu2020, author = {Vu, M.N. and Zips, P. and Lobe, A. and Beck, F. and Kemmetmüller, W. and Kugi, A.}, booktitle = {Proceedings of the 21st IFAC World Congress}, title = {Fast motion planning for a laboratory 3D gantry crane in the presence of obstacles}, doi = {10.1016/j.ifacol.2020.12.2427}, note = {IFAC-PapersOnLine}, number = {2}, pages = {9508--9514}, volume = {53}, address = {Berlin, Germany}, issn = {2405-8963}, month = {06}, year = {2020}, }

28.10.2021 Optimal TCP and Robot Base Placement for Complex Continuous Paths

Project focus

- Computation of the optimal TCP (tool center point) for an industrial robot

- Formulation of an objective function and optimization problem

- Development of a fast underlying path planning algorithm

Description

The robot base placement of an industrial robot w.r.t. to the workpiece is crucial for the execution of a predefined robot motion. This placement is chosen once in the course of planning and constructing the robot work cell. However, in a flexible production environment, the robot trajectories change frequently, and in some cases an expensive and time-consuming repositioning of the robot becomes necessary. This project shows that with small adaptions of the robotic tool, a repositioning of the robot can be avoided.

To this end, an underlying path planning algorithm is developed. This path planner considers wide turning ranges of the robot axes and is capable to plan through kinematic singularities. Based on the path planner, an optimization problem is formulated, with which the optimal TCP for multiple end-effector paths is determined. The objective function of this optimization problem considers the total number of inverse kinematic solutions, the total number of accomplished solutions, the joint movements and the reserves to the mechanical joint limits. Further, by rephrasing the problem, the proposed optimization algorithm is also capable to derive the optimal robot base position. This work is demonstrated for a trim application in a production line, where an optimal TCP and the optimal robot base position is derived.

Video

Selected Publications

- T. Weingartshofer, C. Hartl-Nesic, and A. Kugi, Optimal TCP and Robot Base Placement for a Set of Complex Continuous Paths, in Proceedings of the International Conference on Robotics and Automation (ICRA), Xi’an, China, 2021, pp. 9659-9665.

[BibTex]@InProceedings{Weingartshofer2021, author = {Weingartshofer, T. and Hartl-Nesic, C. and Kugi, A.}, booktitle = {Proceedings of the International Conference on Robotics and Automation (ICRA)}, title = {Optimal TCP and Robot Base Placement for a Set of Complex Continuous Paths}, doi = {10.1109/ICRA48506.2021.9561900}, pages = {9659 - 9665}, address = {Xi'an, China}, issn = {2577-087X}, month = {5}, year = {2021}, }

22.10.2021 Observer-based Iterative Learning Control to Improve Path Accuracy of Industrial Robots

Project Focus

- Modeling of nonlinear effects within the drive train of robots

- Design of precise model-based state observers

- Iterative learning control to improve path accuracy at the end-effector

Description

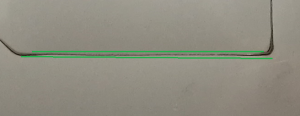

For machining tasks with robots, path accuracy is an essential performance criterion. In many applications, accuracies in the range of tenths of a millimeter and below are required. Examples include the seam sealing of car bodies with robots and laser welding. In these applications, it is not only high static accuracy that is important, but also overall accuracy, which includes tracking errors of the control system, as well as dynamic effects of the mechanical structure. Figure 1 shows the tracking error in laser marking.

A major cause for the deviation from the ideal behavior shown above lies in the drive trains. Here, the gearboxes have the most significant influence. Compared to the ideal behavior, gearboxes exhibit the following behavior:

- Non-uniform friction: due to the varying engagement of the gear teeth, the friction is position-dependent and load-dependent.

- Non-constant gear ratio: due to imperfect tooth flanks, small deviations occur in the endeffector position. For robots 1-3 meters arm length, this can give rise for TCP (Tool Center Point) errors in the range of a few tenths of a millimeter.

- Finite and variable stiffness: due to the compliance of the gearbox, vibrations are excited in interaction with friction and imperfect transmission behavior. If the frequency of the variable stiffness coincides with the resonant frequency of the robot axes, this can lead to very high dynamic errors.

The gear effects are complex, especially in their dynamic interaction. Measurement methods usually require high-priced measuring equipment. Each robot for which compensation is to be used must be measured individually.

The aim of the project is to develop suitable robot models and state observers that incorporate the gear effects described above. Based on this, new control strategies are to be designed with which the growing accuracy requirements can be achieved. The main goal is to combine mechatronic, physical models in an optimal way with the processing of unstructured data in order to achieve the highest possible efficiency and ease of use. Furthermore, to address the availability of highly accurate measurement systems in practice, inexpensive available sensors will be used to guarantee a broad applicability of the developed methods. The measurement data obtained in this way will be used in the course of an iterative learning control to ultimately achieve the desired accuracy, not only in positioning tasks, but also while traversing paths.

Selected Publications

- B. Bischof, T. Glück, M. Böck, and A. Kugi, Path Following Control for Elastic Joint Robots, in Proceedings of the 20th IFAC World Congress, Toulouse, France, 2017, p. 4806–4811.

[BibTex]@InProceedings{Bischof17, author = {Bischof, B. and Gl\"uck, T. and B\"ock, M. and Kugi, A.}, title = {Path Following Control for Elastic Joint Robots}, booktitle = {Proceedings of the 20th IFAC World Congress}, year = {2017}, volume = {50}, number = {1}, month = {7}, pages = {4806--4811}, doi = {10.1016/j.ifacol.2017.08.965}, address = {Toulouse, France}, issn = {2405-8963}, } - B. Bischof, Path and Surface Following Control for Industrial Robotic Applications, A. Kugi and K. Schlacher, Eds., Aachen: Shaker Verlag, 2020, vol. 47.

[BibTex]@Book{Bischof2020, author = {Bischof, Bernhard}, title = {{Path and Surface Following Control for Industrial Robotic Applications}}, year = {2020}, editor = {A. Kugi and K. Schlacher}, volume = {47}, series = {Modellierung und Regelung komplexer dynamischer Systeme}, publisher = {Shaker Verlag}, isbn = {978-3-8440-7200-6}, address = {Aachen}, organization = {Institute f{\"u}r Automatisierungs- und Regelungstechnik (TU Wien) und Regelungstechnik und Prozessautomatisierung (JKU Linz)}, }

13.10.2021 Control strategies for high-energy pulsed laser sources

Project focus

- mathematical modelling and theoretic investigation of involved laser dynamics

- development of adaptive model-based pulse shaping strategies

- suppression of dynamic and stochastic instabilities by means of feedback control

- explore the potential of systematic hardware/software codesign for pulsed laser sources

Description

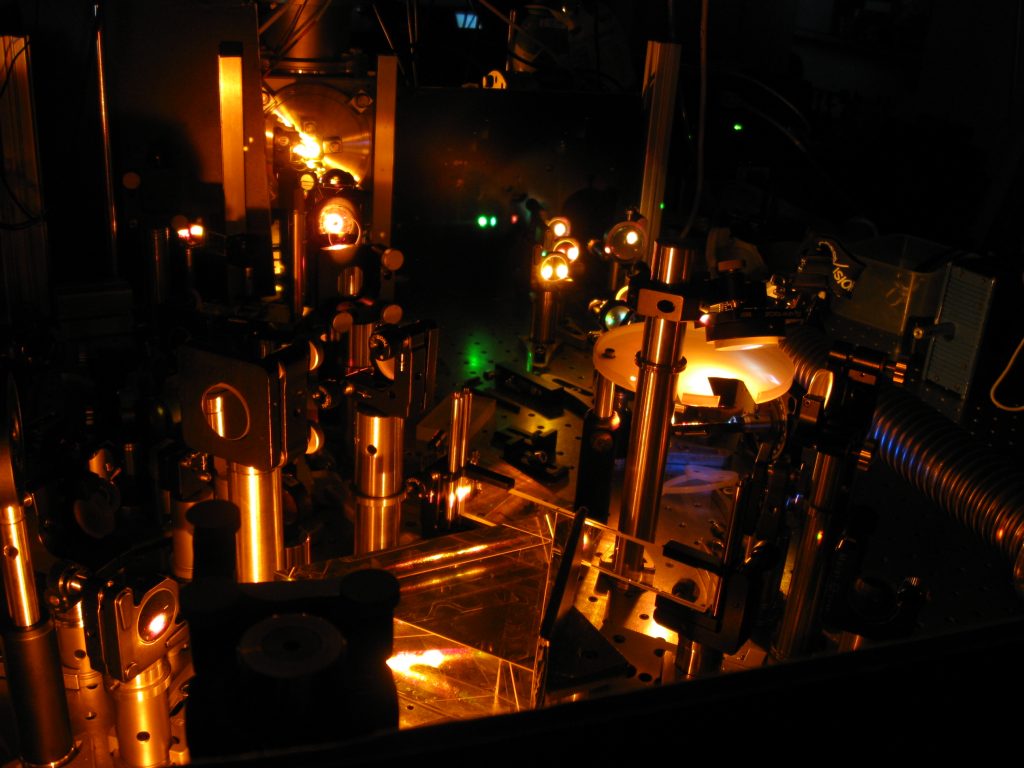

Short high-energy pulses of laser light have become a valuable and flexible tool with applications in basic research (i.e., in strong field physics, for pumping of optical parametric amplifiers and free electron lasers, or for coherent stimulation of atomic of molecular processes) as well as applications such as ablation-based material processing and laser-based eye surgery. The generation of particularly short pulses can be achieved by injecting seed pulses from a pulse source such as a mode-locked laser into resonator cavity with a pumped gain medium inside – a socalled master oscillator power amplifier (MOPA) concept. A more economic approach in case the required pulse durations allow it is to self-seed the cavity from spontaneous emission – a traditional Q-switched laser.

Many current and future applications of pulsed laser light require increasingly extreme operating parameters that entail specific issues depending on the chosen concept. For example, high repetition rates typically favoured in scanning or spectroscopic applications operate pumped resonator cavities close or within their dynamically unstable regime. This is particularly relevant if multiple amplification stages are economically or spatially unfeasible for the intended application. Additionally, the intrinsic stochastic fluctuations in self-seeded cavities often results in large energy fluctuations within the obtained pulse sequences that are highly detrimental for sensing applications. Another problem arises from the broad spectral bandwidth required for ultra-short pulsed operation, which leads to severely distorted and temporally broadened pulse shapes.

The timing requirements of modern pulse sources already largely relies on computerized control methods and the availability of programmable optical actuators such as acousto-optic modulators (AOMs) or spatial light modulators (SLMs). As a result, the application of advanced automatic control schemes can be used to mitigate or eliminate current limitations. Specifically, including the possibility of algorithmic solutions expands the range of strategies during the laser engineering process which in turn leads to more effective, more economic, and more flexible laser systems.

Selected publications

- L. Tarra, A. Deutschmann-Olek, and A. Kugi, Nonlinear feedback stabilisation and stochastic disturbance suppression of actively Q-switched lasers, in Proceedings of the 22nd IFAC World Congress, Yokohama, Japan, 2023 2023, pp. 77-82.

[BibTex]@InProceedings{Tarra2023, author = {Tarra, L. and Deutschmann-Olek, A. and Kugi, A.}, booktitle = {Proceedings of the 22nd IFAC World Congress}, date = {2023}, title = {Nonlinear feedback stabilisation and stochastic disturbance suppression of actively Q-switched lasers}, doi = {10.1016/j.ifacol.2023.10.1550}, number = {2}, pages = {77-82}, volume = {56}, address = {Yokohama, Japan}, issue = {2}, journaltitle = {IFAC-PapersOnLine}, month = {7}, year = {2023}, } - L. Tarra, A. Deutschmann-Olek, V. Stummer, T. Flöry, A. Baltuska, and A. Kugi, Stochastic nonlinear model of the dynamics of actively Q-switched lasers, Optics Express, vol. 30, iss. 18, p. 32411–32427, 2022.

[BibTex]@Article{Tarra2022, author = {Lukas Tarra and Andreas Deutschmann-Olek and Vinzenz Stummer and Tobias Fl\"{o}ry and Anrius Baltuska and Andreas Kugi}, title = {Stochastic nonlinear model of the dynamics of actively Q-switched lasers}, doi = {10.1364/OE.464508}, number = {18}, pages = {32411--32427}, url = {http://opg.optica.org/oe/abstract.cfm?URI=oe-30-18-32411}, volume = {30}, journal = {Optics Express}, keywords = {Amplified spontaneous emission; Fiber lasers; Q switched lasers; Random lasers; Spontaneous emission; Stimulated Brillouin scattering}, month = {Aug}, publisher = {Optica Publishing Group}, year = {2022}, } - A. Deutschmann, W. Kemmetmüller, and A. Kugi, On the global feedback stabilization of regenerative optical amplifiers, in Proceedings of the 21st IFAC World Congress, Berlin, Germany, 2020, p. 5447–5452.

[BibTex]@InProceedings{Deutschmann2020a, author = {A. Deutschmann and W. Kemmetmüller and A. Kugi}, booktitle = {Proceedings of the 21st IFAC World Congress}, title = {On the global feedback stabilization of regenerative optical amplifiers}, doi = {10.1016/j.ifacol.2020.12.1547}, note = {IFAC-PapersOnLine}, number = {2}, pages = {5447--5452}, volume = {53}, address = {Berlin, Germany}, issn = {2405-8963}, month = {06}, year = {2020}, } - A. Deutschmann, T. Flöry, K. Schrom, V. Stummer, A. Baltuška, and A. Kugi, Bifurcation suppression in regenerative amplifiers by active feedback methods, Optics Express, vol. 28, iss. 2, pp. 1722-1737, 2020.

[BibTex] [Download]@Article{Deutschmann2020, author = {Deutschmann, A. and Fl\"ory, T. and Schrom, K. and Stummer, V. and Baltu\v{s}ka, A. and Kugi, A.}, title = {Bifurcation suppression in regenerative amplifiers by active feedback methods}, journal = {Optics Express}, year = {2020}, volume = {28}, number = {2}, pages = {1722-1737}, doi = {10.1364/OE.380404}, } - A. Deutschmann, P. Malevich, A. Baltuska, and A. Kugi, Modeling and iterative pulse-shape control of optical chirped pulse amplifiers, Automatica, vol. 98, p. 150–158, 2018.

[BibTex] [Download]@Article{Deutschmann2018a, author = {Deutschmann, A. and Malevich, P. and Baltuska, A. and Kugi, A.}, title = {Modeling and iterative pulse-shape control of optical chirped pulse amplifiers}, journal = {Automatica}, year = {2018}, volume = {98}, pages = {150--158}, issn = {0005-1098}, doi = {10.1016/j.automatica.2018.09.002}, }

Partners

Ultrafast Laser Group, Photonics Institute at TU Wien

29.06.2021 Time-optimal fold-out of a mobile concrete pump

Project description

Mobile concrete pumps are used on construction sites to transport concrete from the cement mixer to the formwork. Such machines typically comprise a pump and a boom equipped with concrete convey pipes, see Fig. 1. To enable a large operating range (up to approx. 60m) while being able to transport the boom on a standard truck, the boom of these mobile concrete pumps is constructed in a lightweight design. Due to the complex kinematics with up to 6 individual joints and the large working areas, an optimal manual operation by a human operator is cognitively not possible.

A mobile concrete pump during operation.

In the current state of the art the actuator velocities of such manipulators are heavily limited to ensure safe operation. The complex motion of folding out the boom is performed sequentially by simultaneously movement of maximum 2-3 joints. Furthermore well experienced operating staff is required. The trend in the off-highway sector shows a significant increase in more complex assistance systems in the last years, helping the operating staff actively concerning user comfort and increased safety during autonomous operation.

Project focus

In this research project, a system is developed to obtain time-optimal, collision-free motions of the boom of a mobile concrete pump. The resulting trajectories for the joint angles consider the technical limitations of the joint angles and joint angular velocities as well as legal restrictions concerning Cartesian velocities. Furthermore, if the support feet of the machine are not fully extended (e.g. due to limited space on site), the working area of the manipulator is systematically limited. The developed concept is tested and validated on a real machine with 5 individual rotational joints.

Selected publications

- J. Henikl, W. Kemmetmüller, and A. Kugi, Estimation and control of the tool center point of a mobile concrete pump, Automation in Construction, vol. 61, p. 112–123, 2016.

[BibTex] [Download]@Article{Henikl16, Title = {Estimation and control of the tool center point of a mobile concrete pump}, Author = {Henikl, J. and Kemmetm\"uller, W. and Kugi, A.}, Journal = {Automation in Construction}, Pages = {112--123}, Volume = {61}, Year = {2016}, Doi = {10.1016/j.autcon.2015.10.005}, ISSN = {0926-5805}, } - J. Henikl, W. Kemmetmüller, T. Meurer, and A. Kugi, Infinite-dimensional decentralized damping control of large-scale manipulators with hydraulic actuation, Automatica, vol. 63, p. 101–115, 2016.

[BibTex] [Download]@Article{Henikl16a, Title = {Infinite-dimensional decentralized damping control of large-scale manipulators with hydraulic actuation}, Author = {Henikl, J. and Kemmetm\"uller, W. and Meurer, T. and Kugi, A.}, Journal = {Automatica}, Pages = {101--115}, Volume = {63}, Year = {2016}, Doi = {10.1016/j.automatica.2015.10.024}, ISSN = {0005-1098}, } - J. Henikl, W. Kemmetmüller, M. Bader, and A. Kugi, Modeling, Simulation and Identification of a Mobile Concrete Pump, Mathematical and Computer Modelling of Dynamical Systems, vol. 21, iss. 2, p. 180–201, 2015.

[BibTex] [Download]@Article{Henikl14, Title = {Modeling, Simulation and Identification of a Mobile Concrete Pump}, Author = {Henikl, J. and Kemmetm\"uller, W. and Bader, M. and Kugi, A.}, Journal = {Mathematical and Computer Modelling of Dynamical Systems}, Pages = {180--201}, Volume = {21}, Year = {2015}, Number = {2}, Doi = {10.1080/13873954.2014.926277}, } - M. Meiringer, A. Kugi, and K. W., Time-optimal fold out of large-scale manipulators with obstacle avoidance, in Proceedings of the 11th IFAC Symposium on Nonlinear Control Systems NOLCOS 2019, Vienna, Austria, 2019, pp. 114-119.

[BibTex]@InProceedings{Meiringer2019, author = {Meiringer, M. and Kugi, A. and Kemmetm\"uller W.}, title = {Time-optimal fold out of large-scale manipulators with obstacle avoidance}, booktitle = {Proceedings of the 11th IFAC Symposium on Nonlinear Control Systems NOLCOS 2019}, year = {2019}, volume = {52}, number = {16}, month = {9}, pages = {114-119}, doi = {10.1016/j.ifacol.2019.11.765}, address = {Vienna, Austria}, issn = {2405-8963}, } - W. Kemmetmüller, M. Meiringer, V. Platzgummer, and A. Kugi, Optimale Abstützung eines mobilen Großraummanipulators, at – Automatisierungstechnik, vol. 69, iss. 9, p. 782–794, 2021.

[BibTex]@Article{Kemmetmueller2021, author = {Wolfgang Kemmetmüller and Martin Meiringer and Valentin Platzgummer and Andreas Kugi}, title = {Optimale Abstützung eines mobilen Großraummanipulators}, doi = {doi:10.1515/auto-2021-0052}, number = {9}, pages = {782--794}, url = {https://doi.org/10.1515/auto-2021-0052}, volume = {69}, journal = {at -- Automatisierungstechnik}, year = {2021}, } - M. Meiringer, A. Kugi, and W. Kemmetmüller, Modelling and calibration of a five link elastic boom of a mobile concrete pump, Mathematical and Computer Modelling of Dynamical Systems, vol. 29, iss. 1, p. 41–68, 2023.

[BibTex] [Download]@Article{Meiringer2023, author = {M. Meiringer and A. Kugi and W. Kemmetm\"uller}, title = {Modelling and calibration of a five link elastic boom of a mobile concrete pump}, doi = {10.1080/13873954.2023.2177311}, number = {1}, pages = {41--68}, volume = {29}, journal = {Mathematical and Computer Modelling of Dynamical Systems}, year = {2023}, } - M. Meiringer, A. Kugi, and W. Kemmetmüller, Semi-autonomous operation of a mobile concrete pump, Automation in Construction, vol. 156, p. 105079, 2023.

[BibTex]@Article{Meiringer2023a, author = {Meiringer, M. and Kugi, A. and Kemmetm\"uller, W.}, title = {Semi-autonomous operation of a mobile concrete pump}, doi = {10.1016/j.autcon.2023.105079}, pages = {105079}, volume = {156}, journal = {Automation in Construction}, year = {2023}, }

08.03.2021 Digital Literacy in Robotics & Informatics – for underprivileged people

Robotics and computer science are not imaginable without digital competence. Both are a possible entry into the digital world and promote the development of digital competence. However, the question also needs to be asked as to which barriers arise in the digital world and how these can be overcome. To this end, a working group with interdisciplinary members from different partner universities will be constituted to make common barriers visible and propose improvements for gender-appropriate didactic concepts.

Partners:

TU Wien ACIN Institut für Automatisierungs- und Regelungstechnik

TU Wien Department of Geodesy Geoinformation

FH Technikum Wien Digital Manufacturing & Robotics

FH Technikum Wien Informatik

Universität Wien, Institut für Bildungswissenschaften

Funding:

The Projectnumber is GEV376020CTS.

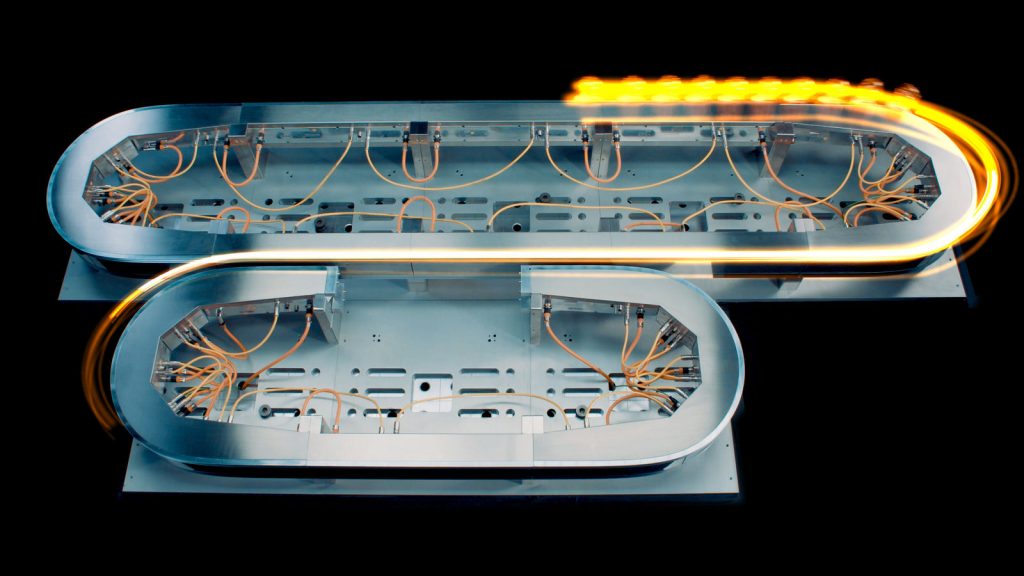

08.10.2020 Modelling and optimal control of a linear motor

Project focus

- Modeling of the linear motor

- Optimal currents for different use cases

- Development of a control concept for position control of one or more transport units

Description

The usage of long stator linear motors provides higher flexibility in a transport system for production plants compared to common conveyor belt systems. The usage of multiple transport units offers the advantage that the distances between the transport units, and thus the run-time of the transport process itself, can be freely chosen. In order to guarantee a high-dynamic operation it is necessary to obtain an accurate model of the motor and an optimal control strategy.

B&R Industrial Automation GmbH

A main challenge when describing the behavior of electric machines are the systematic consideration of nonlinear magnetic material saturation and of nonlinear cogging forces along the transport motion. The modeling method chosen in this project uses magnetic equivalent circuits and allows a systematic derivation of a motor model, which is able to consider these phenomena. Based on the derived model, a optimal control problem is formulated, which yields optimal currents of the motor coils such that a given tractive and normal force is obtained for the transport units. Additionaly, existing efficiency constraints are taken into account for the calculated optimal currents. The positioning of one or multiple transport units is done using the calculated optimal currents. A further challenge arises from the task to guarantee positioning accuracy while moving multiple transport units within a very short distances between them.

Project partner

B&R Industrial Automation GmbH

21.02.2020 Application of Curved Tapes on 3D Objects

Project focus

- Application of pre-cut tapes on freeform 3D surface

- Draping process with a defined normal force

- Traverse a tool along a surface-based path on a freeform 3D surface

Description

Robotic handling of deformable materials like, e. g. textiles, carbon and glass fiber fabrics, foils and paper, has been a challenging task in the industry for a long time, and has received great attention in research recently. Flexible automation on a human level has not yet been fully achieved for many handling tasks like, e. g., grasping, de-stacking and draping. The main challenges for the automated handling of deformable materials are their characteristics, in particular the nonlinear material behavior, the anisotropy, the diverse outer contours, the high dimensionality of the object state, and the wide range of material properties like porosity and density. In this context, many specialized mechatronic gripper solutions were implemented for grasping and transporting. However, high-mix and low-volume tasks require more flexible solutions.

This project presents a flexible approach for impedance-controlled wrinkle-free application of (curved) pre-cut adhesive tapes on freeform 3D surfaces. For this application, a surface-based path following control concept is developed, which provides a local coordinate frame based on the surface normal and the path tangent. Furthermore, the algorithms and solutions emerging from this application also represent a solution for a more general robotic problem, i. e. traversing a tool along a curved path on a freeform 3D surface with defined kinematic constraints.

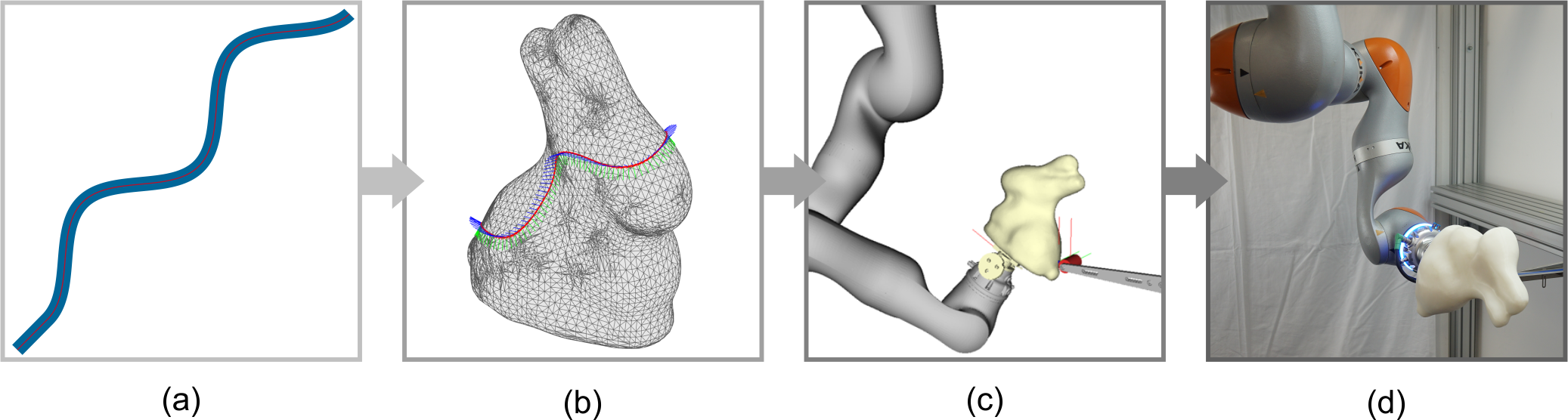

The tape application process consists of the following steps and is depicted in Fig. 1:

- (a) 2D tape application path: A planar tape application path is created on the shape of the planar tape

- (b) 3D path mapping: The geometry and curvature of the planar tape application path is mapped onto the CAD model of the 3D object, which creates a 3D tape application path.

- (c) Robot starting pose: The tape application process is simulated to determine a suitable starting joint configuration for the robot which results in a collisionfree execution and has a reasonable reserve with respect to the joint limits.

- (d) Preparation and execution: The pre-cut tape is placed in the required starting position on the feed of the application tool and the robot performs the impedance-controlled tape application process.

Tape application process overview: (a) 2D tape application path, (b) 3D path mapping, (c) Robot starting pose, (d) Preparation and execution.

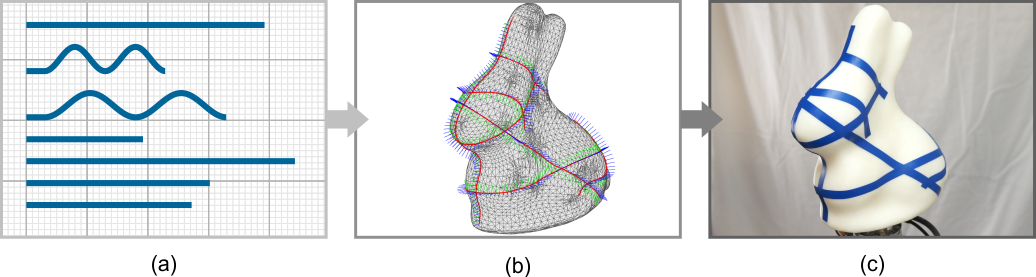

The surface-based path following control concept is demonstrated on a 3D-printed object, as shown in Fig. 2: The paths of the pre-cut tapes in (a) are mapped onto the discrete surface of the 3D object in (b). The tape application result is depicted in (c).

Experimental results of the tape application process on a 3D-printed object: (a) Pre-cut tapes (b) Projected paths on 3D object (c) Completed tape application

Videos

Selected publications

- T. Weingartshofer, M. Schwegel, C. Hartl-Nesic, T. Glück, and A. Kugi, Collaborative Synchronization of a 7-Axis Robot, in Proceedings of the 8th IFAC Symposium on Mechatronic Systems MECHATRONICS 2019, Vienna, Austria, 2019, pp. 507-512.

[BibTex]@InProceedings{Weingartshofer2019, author = {Weingartshofer, T. and Schwegel, M. and Hartl-Nesic, C. and Gl\"uck, T. and Kugi, A.}, title = {Collaborative Synchronization of a 7-Axis Robot}, booktitle = {Proceedings of the 8th IFAC Symposium on Mechatronic Systems MECHATRONICS 2019}, year = {2019}, volume = {52}, number = {15}, month = {9}, pages = {507-512}, doi = {10.1016/j.ifacol.2019.11.726}, address = {Vienna, Austria}, issn = {2405-8963}, } - C. Hartl-Nesic, B. Bischof, T. Glück, and A. Kugi, Pfadfolgeregelung mit Konzepten für den Pfadfortschritt: Ein Assemblierungsszenario, at – Automatisierungstechnik, vol. 68, iss. 1, p. 44–57, 2020.

[BibTex]@Article{Hartl-Nesic2020, author = {Hartl-Nesic, Christian and Bischof, Bernhard and Gl{\"u}ck, Tobias and Kugi, Andreas}, title = {Pfadfolgeregelung mit Konzepten für den Pfadfortschritt: Ein Assemblierungsszenario}, journal = {at -- Automatisierungstechnik}, year = {2020}, volume = {68}, number = {1}, pages = {44--57}, issn = {2196-677X}, doi = {10.1515/auto-2019-0114}, } - C. Hartl-Nesic, Surface-Based Path Following Control on Freeform 3D Objects, A. Kugi, K. Schlacher, and W. Kemmetmüller, Eds., Düren: Shaker Verlag, 2020, vol. 49.

[BibTex]@Book{HartlNesic2020, author = {Hartl-Nesic, C.}, title = {Surface-Based Path Following Control on Freeform 3D Objects}, editor = {A. Kugi and K. Schlacher and W. Kemmetm\"uller}, isbn = {978-3-8440-7637-0}, publisher = {Shaker Verlag}, series = {Modellierung und Regelung komplexer dynamischer Systeme}, volume = {49}, address = {D\"uren}, organization = {Institute f{\"u}r Automatisierungs- und Regelungstechnik (TU Wien) und Regelungstechnik und Prozessautomatisierung (JKU Linz)}, year = {2020}, } - C. Hartl-Nesic, T. Glück, and A. Kugi, Surface-Based Path Following Control: Application of Curved Tapes on 3-D Objects, IEEE Transactions on Robotics, vol. 37, iss. 2, p. 615–626, 2021.

[BibTex] [Download]@Article{HartlNesic2021, author = {Hartl-Nesic, Ch. and Gl{\"u}ck, T. and Kugi, A.}, title = {Surface-Based Path Following Control: Application of Curved Tapes on 3-D Objects}, doi = {10.1109/TRO.2020.3033721}, issn = {1552-3098}, number = {2}, pages = {615--626}, volume = {37}, journal = {IEEE Transactions on Robotics}, year = {2021}, }

Applications

- Textile/garment industry

- Fiber reinforced plastics industry

- Food industry

22.01.2020 Mathematical modelling, optimization and quality monitoring for side-trimming of heavy steel plates

Project focus

- Analysis and modeling of the side-trimming process of heavy steel plates

- Optimization of the process and the machine design

- Root cause analysis and minization of common quality defects

- Development of a camera- and laser-based quality monitoring system

Description

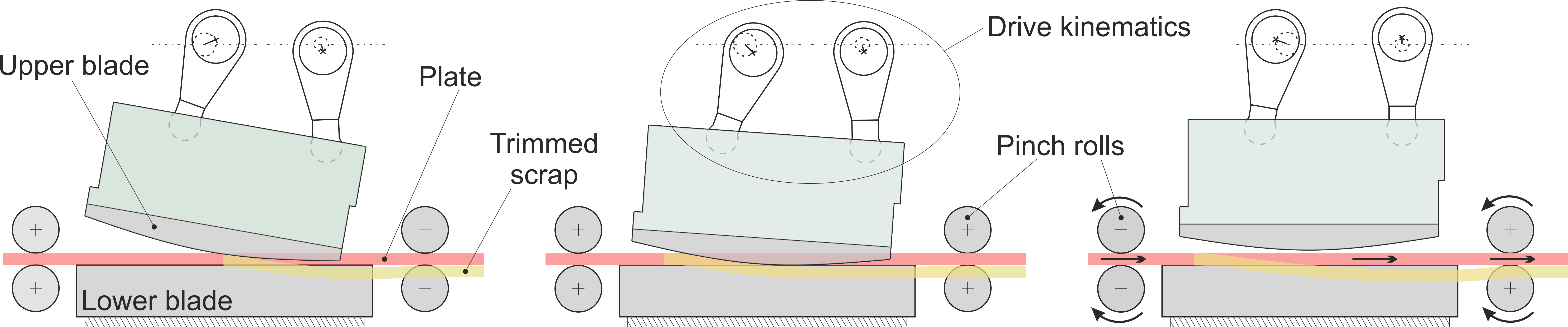

Side-trimming is an essential process step in the steel industry. The objective of this shearing process is to obtain rectangularly shaped heavy plates after the rolling process. Rolling-cut trimming shears perform this task stepwise and purely mechanically by a rolling-cuts of arc-shaped trimming blades. Due to plate thicknesses up to 45mm, the process forces can reach values of 5MN. Although rolling-cut shearing is the most common method for side-trimming of heavy steel plates, it may entail quality defects like broken edge surfaces, unevenly trimmed edges, or burr. Furthermore, the trimming process might cause a deviation of the plate contour from its ideal rectangular shape.

Principle of rolling-cut shearing for side-trimming of rolled plates.

In this research project, it was found that the lateral process forces acting on the cutting blades have a significant influence on the resulting quality of the trimmed edges. An objective of this project is therefore to obtain a constant lateral process force by optimization of the machine design and the drive kinematics. As a consequence, both quality defects of the trimmed edges and wear of the cutting blades would be reduced.

Another strand of this research project is the development of an automatic quality monitoring system. This system evalutates the quality and the geometric accuracy of each trimmed edge using machine vision and laser-sensor technology. The generated and stored data sets can be used for optimizing the adjustable process parameters and for predictive maintenance of the cutting blades.

Selected publications

- A. Zeiler, A. Steinboeck, A. Kugi, and M. Jochum, Lateral Forces in Rolling-Cut Shearing and Their Consequences on Common Edge Defects, Journal of Manufacturing Science and Engineering, vol. 141, iss. 4, p. 41001-1–41001-9, 2019.

[BibTex] [Download]@Article{Zeiler2019, author = {Zeiler, A. and Steinboeck, A. and Kugi, A. and Jochum, M.}, title = {Lateral Forces in Rolling-Cut Shearing and Their Consequences on Common Edge Defects}, journal = {Journal of Manufacturing Science and Engineering}, year = {2019}, volume = {141}, number = {4}, pages = {41001-1--41001-9}, doi = {10.1115/1.4042578}, } - A. Zeiler, A. Steinboeck, M. Vincze, M. Jochum, and A. Kugi, Vision-based inspection and segmentation of trimmed steel edges, in Proceedings of the 18th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing, Stellenbosch, South Africa, 2019, p. 165–170.

[BibTex]@InProceedings{Zeiler2019a, author = {Zeiler, A. and Steinboeck, A. and Vincze, M. and Jochum, M. and Kugi, A.}, title = {Vision-based inspection and segmentation of trimmed steel edges}, booktitle = {Proceedings of the 18th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing}, year = {2019}, month = {8}, pages = {165--170}, doi = {10.1016/j.ifacol.2019.09.182}, address = {Stellenbosch, South Africa}, }

Applications

- Shearing processes

- Automation of rolling mills

- Continuous production processes

23.10.2019 Omron

The purpose of this project is to develop a software for estimating 6D pose and grasping points of non-rigid objects in bin-picking scenarios. This software would be used with industrial robots for picking individually different shaped objects like toys, vegetables, and fruits those are randomly piled in boxes or on belt conveyors. Multiple objects of one type are in a box or on a conveyor.

FUNDING:

Company Funding