Optimal Control of pneumatic linear drives

This project aims at robust but cost effective solutions for the most common industrial application of pneumatic linear drives, namely point-to-point movements. For this a suited setup for reduced investment costs is chosen. The setup consists of four leakage free fast switching valves, which are interconnected to two half bridges, three low cost pressure sensors and two small piecewise position sensors. The combination of modern control concepts and tailored trajectory planning strategies allows to move the drive even under typical variations in the working conditions. Subsequently the developed concepts are validated by means of measurements on lab test benches. Read more →

Soft landing strategies for electromagnetic fast-switching valves

This project is concerned with the development of a soft landing control strategy electromagnetic valves. The main goal is to guarantee time-optimal switching of the valves with minimal impact velocity of the plunger at the limit stops. Thus, the approach combines the benefits of fast response and low maintenance intervals. Read more →

Automated Handling of Highly Deformable Materials

In this project, a prototype of a handling system is set up and the potential of modern model-based control to handle limp materials is examined. The concepts are applicable to many other issues, such as the automated lamination of large vinyl sheets, textile handling, etc. Read more →

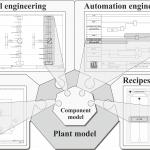

Component-based design of industrial control applications utilizing formal methods

The project scope includes the development of a library of standardized software components. Such software components enable a simplified implementation of industrial control applications by composition of such components on an abstract level. Furthermore, the library components already define integrated basic control functionality of the underlying hardware component and provide services for connecting several components in a flexible manner with each other (application integration). Read more →