15.05.2017 Soft landing strategies for electromagnetic fast-switching valves

Project focus

- Time-optimal feedforward controller design for soft landing

Description

The increasing cost pressure on mechatronic products in fluid power applications demands the development of cheap and reliable electromagnetic control valves. In servo control of pneumatic piston cylinders, for instance, the expensive directional control valve may be replaced by a pneumatic full bridge consisting of low-cost fast-switching valves. In other industrial applications, like for example in the food industry, fast-switching valves are utilized to perform sorting tasks with the ever increasing demand for higher cycle times and a longer lifetime. Thus in all these applications, electromagnetic valves must exhibit fast valve switching times in order to achieve a high bandwidth and a maximum throughput. At the same time, a minimum impact velocity of the valve plunger has to be guaranteed to reduce noise and wear of the mechanical components. Strategies ensuring a minimum impact velocity of the valve plunger are frequently called soft landing strategies.

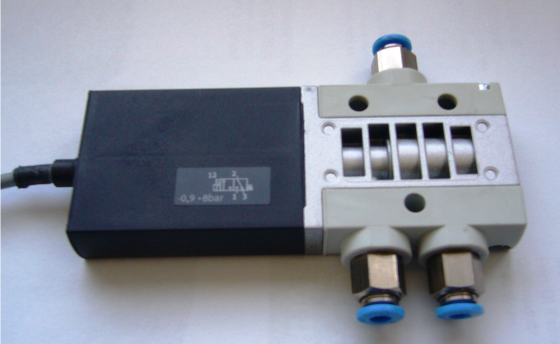

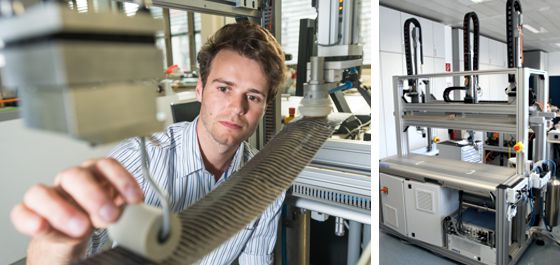

Fast-switching valve.

This project is concerned with the development of a soft landing control strategy that guarantees the time-optimal switching of electromagnetic valves with minimal impact velocity of the plunger at the limit stops.

The feedforward controller is based on the formulation of an input-constrained, time-optimal control problem for the point-to-point motion of the plunger. For this purpose, a mathematical model of a fast-switching valve is derived and the quasi-time-optimal and the time-optimal case are examined. In addition to the numerical solution of the quasi-time-optimal control problem utilizing a full-discretization, the input-constrained time-optimal control problem is reformulated by applying Pontryagin’s maximum principle providing an equivalent two-point boundary value problem. In this representation, it is evident that the input-constrained and time-optimal solution for the opening and closing of the valve is a bang-singular-bang control.

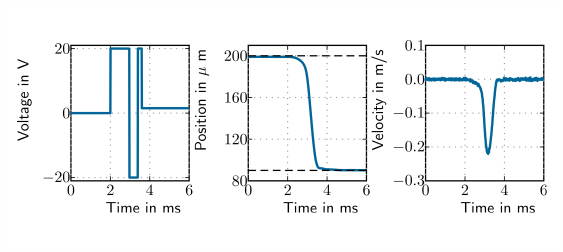

Optimal trajectory for the opening of the valve.

Measurement results at a test bench confirm the theoretical results and demonstrate the feasibility of the proposed approach. Fig. 1 shows the bang-bang input control for the opening and the resulting position and velocity of the plunger. This optimal feedforward control concept has been applied for a patent and is going to be implemented in the series production by the industrial partner.

Selected publications

- T. Glück, W. Kemmetmüller, A. Pfeffer, and A. Kugi, Pneumatic pulse-width modulated pressure control via trajectory optimized fast-switching electromagnetic valves, in Proceedings of the 13th Mechatronics Forum, Linz, Austria, 2012, p. 692 – 699.

[BibTex] [Download]@InProceedings{Gluck12, author = {T. Gl{\"u}ck and W. Kemmetm{\"u}ller and A. Pfeffer and A. Kugi}, title = {{Pneumatic pulse-width modulated pressure control via trajectory optimized fast-switching electromagnetic valves}}, booktitle = {Proceedings of the 13th Mechatronics Forum}, year = {2012}, month = {9}, pages = {692 -- 699}, address = {Linz, Austria}, } - T. Glück, W. Kemmetmüller, and A. Kugi, Trajectory optimization for soft landing of fast-switching electromagnetic valves, in Proceedings of the 18th IFAC World Congress, Milano, Italia, 2011, p. 11532–11537.

[BibTex] [Download]@InProceedings{Glueck11b, author = {T. Gl\"uck and W. Kemmetm\"uller and A. Kugi}, title = {{T}rajectory optimization for soft landing of fast-switching electromagnetic valves}, booktitle = {Proceedings of the 18th IFAC World Congress}, year = {2011}, month = {8}, pages = {11532--11537}, doi = {10.3182/20110828-6-IT-1002.01822}, address = {Milano, Italia}, }

Applications

- Pneumatic drives

- Food industry

15.05.2017 Thermal model and optimal time scheduling of hot rolling

Project focus

- Modeling of the temperature evolution of plates during hot rolling

- Observer design based on pyrometer measurements

- Optimization of processing times

Description

In the production of heavy plates, it is important to know the current temperature of the product and to adjust it by adaptation of process times. The temperature evolution is decisive for the production process because many mechanical properties of the product are temperature-dependent, e.g., the yield stress. Furthermore, the temperature evolution also influences the microstructure and thus other important material properties of the final product.

Heavy plate rolling mill, Copyright: Dillinger Hüttenwerke AG.

The production steps of hot rolling influence the plate temperature in different ways: On the one hand, the plate temperature decreases due to air cooling or the contact with water and the work rolls. On the other hand, the deformation in the roll passes leads to a rise of the plate temperature. The thermal model has to capture these different aspects.

Scaled slab on the roller table, © Dillinger Hüttenwerke AG.

By means of the thermal model, the waiting periods that are necessary for the plates to reach their desired rolling temperatures in each pass can be calculated with higher accuracy. Consequently, not only a higher quality of the final product can be achieved, but the production process can also be organized more efficiently because the waiting times can be planned more precisely.

To cope with model inaccuracies or unexpected disturbances, a model-based observer corrects the model predictions. The observer uses measurements of the product surface temperature. As contact measurements are infeasible due to the moving surfaces and the difficult measurement conditions, the surface temperature has to be measured by pyrometers. However, these pyrometer measurements are only feasible at discrete points outside the mill stands. The scarcity of measurements is an additional challenge for the observer design.

Selected Publications

- F. Schausberger, K. Speicher, A. Steinboeck, M. Jochum, and A. Kugi, Two Illustrative Examples to Show the Potential of Thermography for Process Monitoring and Control in Hot Rolling, in Proceedings of the 4th IFAC Workshop on Mining, Mineral and Metal Processing (MMM), Oulu, Finland, 2015, p. 48–53.

[BibTex] [Download]@InProceedings{Schausberger15c, author = {Schausberger, F. and Speicher, K. and Steinboeck, A. and Jochum, M. and Kugi, A.}, title = {Two Illustrative Examples to Show the Potential of Thermography for Process Monitoring and Control in Hot Rolling}, booktitle = {Proceedings of the 4th IFAC Workshop on Mining, Mineral and Metal Processing (MMM)}, year = {2015}, volume = {48}, number = {17}, month = {8}, pages = {48--53}, doi = {10.1016/j.ifacol.2015.10.076}, address = {Oulu, Finland}, issn = {2405-8963}, } - K. Speicher, A. Steinboeck, A. Kugi, D. Wild, and T. Kiefer, A plate temperature model used for planning and online adaptation of the roll pass schedule in hot rolling, in Proceedings of METEC and 2nd European Steel Technology and Application Days (ESTAD), Düsseldorf, Germany, 2015.

[BibTex]@InProceedings{Speicher15, author = {Speicher, Katrin and Steinboeck, Andreas and Kugi, Andreas and Wild, D. and Kiefer, T.}, title = {A plate temperature model used for planning and online adaptation of the roll pass schedule in hot rolling}, booktitle = {Proceedings of METEC and 2nd European Steel Technology and Application Days (ESTAD)}, year = {2015}, month = {6}, address = {D{\"u}sseldorf, Germany}, } - K. Speicher, A. Steinboeck, A. Kugi, D. Wild, and T. Kiefer, Analysis and design of an Extended Kalman Filter for the plate temperature in heavy plate rolling, Journal of Process Control, vol. 24, iss. 9, p. 1371–1381, 2014.

[BibTex] [Download]@Article{Speicher14a, Title = {Analysis and design of an Extended Kalman Filter for the plate temperature in heavy plate rolling}, Author = {Speicher, K. and Steinboeck, A. and Kugi, A. and Wild, D. and Kiefer, T.}, Journal = {Journal of Process Control}, Pages = {1371--1381}, Volume = {24}, Year = {2014}, Number = {9}, Doi = {10.1016/j.jprocont.2014.06.004}, } - K. Speicher, A. Steinboeck, D. Wild, T. Kiefer, and A. Kugi, An integrated thermal model of hot rolling, Mathematical and Computer Modelling of Dynamical Systems, vol. 20, iss. 1, p. 66–86, 2014.

[BibTex] [Download]@Article{Speicher14, Title = {{An integrated thermal model of hot rolling}}, Author = {K. Speicher and A. Steinboeck and D. Wild and T. Kiefer and A. Kugi}, Journal = {Mathematical and Computer Modelling of Dynamical Systems}, Pages = {66--86}, Volume = {20}, Year = {2014}, Number = {1}, Doi = {10.1080/13873954.2013.809364}, } - K. Speicher, A. Steinboeck, and A. Kugi, Measurement Errors of Radiation Pyrometers, in Proceedings of Rolling 2013, Venezia, Italy, 2013, p. 1–12.

[BibTex]@InProceedings{Speicher13a, author = {K. Speicher and A. Steinboeck and A. Kugi}, title = {{{M}easurement {E}rrors of {R}adiation {P}yrometers}}, booktitle = {Proceedings of Rolling 2013}, year = {2013}, month = {6}, pages = {1--12}, address = {Venezia, Italy}, } - K. Speicher, A. Steinboeck, D. Wild, T. Kiefer, and A. Kugi, Estimation of plate temperatures in hot rolling based on an extended Kalman filter, in Proceedings of 15th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral & Metal Processing, San Diego, USA, 2013, p. 409 – 414.

[BibTex]@InProceedings{Speicher13, author = {K. Speicher and A. Steinboeck and D. Wild and T. Kiefer and A. Kugi}, title = {{Estimation of plate temperatures in hot rolling based on an extended Kalman filter}}, booktitle = {Proceedings of 15th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral \& Metal Processing}, year = {2013}, month = {8}, pages = {409 -- 414}, doi = {10.3182/20130825-4-US-2038.00006}, address = {San Diego, USA}, } - K. Speicher, A. Steinboeck, T. Kiefer, and A. Kugi, Modeling Thermal Shocks and Air Cooling Using the Finite Difference Method, in Proceedings MATHMOD 2012 Vienna, Wien, Austria, 2012, p. 364–368.

[BibTex]@InProceedings{Speicher12, author = {K. Speicher and A. Steinboeck and T. Kiefer and A. Kugi}, title = {{{M}odeling {T}hermal {S}hocks and {A}ir {C}ooling {U}sing the {F}inite {D}ifference {M}ethod}}, booktitle = {Proceedings MATHMOD 2012 Vienna}, year = {2012}, editor = {Troch, I. and Breitenecker, F.}, month = {2}, pages = {364--368}, doi = {10.3182/20120215-3-AT-3016.00064}, address = {Wien, Austria}, }

Applications

- Automation of rolling mills

- Scheduling of cooling processes

08.05.2017 Optimization of process times and product sequences in a hot-rolling mill with batch-type reheating furnaces

Project focus

Focus of TU Wien – ACIN within the SemI40 project:

- Mathematical modeling of batch-type reheating furnaces

- Time-optimal control of batch-type reheating furnaces

- Optimal timetabling of reheating, rolling, and handling tasks

- Optimization of the product sequence for a finite production horizon

Description

In semiconductor manufacturing, sputtering processes require pure metals or special alloys for sputtering targets. These targets must fulfill rigorous quality requirements in terms of shape, chemical purity, and microstructure to guarantee high-end semicondutor production. Sputtering targets with high melting points (e.g., molybdenum) are usually produced by sintering and subsequent hot-forming. Metal powders are pressed and sintered in the shape of blocks. Subsequently, these blocks are reheated in furnaces and rolled into plates (targets) by a hot-rolling mill.

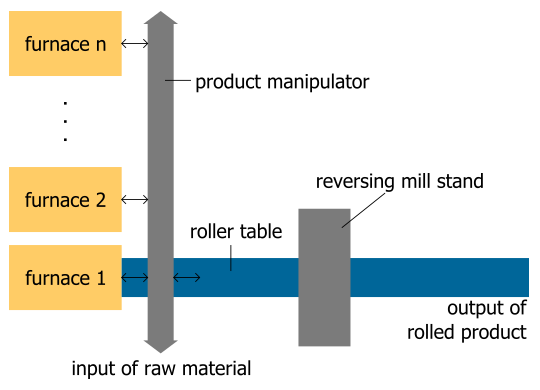

Outline of the production plant.

Figure 1 shows an outline of the considered plant. It consists of several furnaces which may be operated at different temperatures, a roller table with a reversing mill stand, and a product manipulator. The manipulator is used for all product transportation tasks between the furnaces and the roller table. The reheating process of the products in the furnaces is much more time consuming than the rolling passes at the reversing mill stand. Moreover, intermediate reheating steps are necessary between some rolling passes. Due to the fact that hot products cannot be stored, the availability of the required machines at the respective times has to be guaranteed. Hence, the productivity of the plant depends strongly on the required reheating times and the temporal shuffling of the process tasks. The goals of this project are to minimize the reheating times and to optimize the product sequence and the starting times of the process tasks to achieve the maximum product throughput.

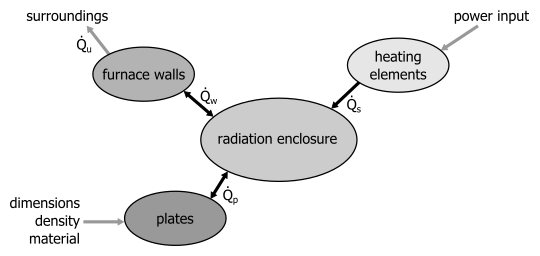

A thermal simulation model for the product and furnace temperatures is developed as a basis for the minimization of the reheating times. Figure 2 shows its general components. Based on the simulation model, minimal reheating times can be determined in advance and the temperature evolution of the products can be estimated during the reheating processes. The reheating time of a product depends strongly on its radiation emissivity, which is subject to uncertainty. A good a-priori estimate of the emissivity of a product is obtained by the developed system by analyzing the reheating results of previously reheated similar products. For this purpose, the products are clustered into groups and the mean emissivity of each group is estimated over time. The developed model can be used as a design model for a time-optimal control strategy of the reheating furnaces.

Thermal modeling of the furnaces.

Furthermore, a software tool is developed which optimizes the product sequence and the process times of all process tasks. This NP-hard combinatorial optimization problem (flexible job shop scheduling problem) is split into the determination of the process times for a known product sequence (timetabling problem) and a superordinate optimization of the product sequence. The optimal process times are determined by a tailored recursive algorithm, and the product sequence is optimized using heuristic methods. The sofware tool performs a receeding horizon planning with a finite horizon length and thus is able to react to unforeseen changes in the planned schedule.

Selected publications

- A. Aschauer, F. Roetzer, A. Steinboeck, and A. Kugi, Efficient scheduling of a stochastic no-wait job shop with controllable processing times, Expert Systems with Applications, vol. 162, p. 113879, 2020.

[BibTex] [Download]@Article{Aschauer2020, author = {Aschauer, A. and Roetzer, F. and Steinboeck, A. and Kugi, A.}, title = {Efficient scheduling of a stochastic no-wait job shop with controllable processing times}, doi = {10.1016/j.eswa.2020.113879}, pages = {113879}, volume = {162}, journal = {Expert Systems with Applications}, month = {7}, year = {2020}, }

- F. Rötzer, A. Aschauer, L. Jadachowski, A. Steinboeck, and A. Kugi, Temperature Control for Induction Heating of Thin Strips, in Proceedings of the 21st IFAC World Congress, Berlin, Germany, 2020, p. 11968–11973.

[BibTex]@InProceedings{Roetzer2020, author = {F. R\"otzer and A. Aschauer and L. Jadachowski and A. Steinboeck and A. Kugi}, booktitle = {Proceedings of the 21st IFAC World Congress}, title = {Temperature Control for Induction Heating of Thin Strips}, doi = {10.1016/j.ifacol.2020.12.722}, note = {IFAC-PapersOnLine}, number = {2}, pages = {11968--11973}, volume = {53}, address = {Berlin, Germany}, issn = {2405-8963}, month = {06}, year = {2020}, }

- A. Aschauer, F. Roetzer, A. Steinboeck, and A. Kugi, Scheduling of a Flexible Job Shop with Multiple Constraints, in Proceedings of the 16th IFAC Symposium on Information Control Problems in Manufacturing INCOM, Bergamo, Italy, 2018, pp. 1293-1298.

[BibTex]@InProceedings{Aschauer2018, author = {Aschauer, A. and Roetzer, F. and Steinboeck, A. and Kugi, A.}, title = {Scheduling of a Flexible Job Shop with Multiple Constraints}, booktitle = {Proceedings of the 16th IFAC Symposium on Information Control Problems in Manufacturing INCOM}, year = {2018}, volume = {51}, number = {11}, month = {6}, pages = {1293-1298}, doi = {10.1016/j.ifacol.2018.08.354}, address = {Bergamo, Italy}, issn = {2405-8963}, }

- F. Rötzer, A. Aschauer, A. Steinboeck, and A. Kugi, A Computationally Efficient 3D Mathematical Model of a Molybdenum Batch-Reheating Furnace, in Proceedings of the 9th Vienna International Conference on Mathematical Modelling (MATHMOD), Vienna, Austria, 2018, p. 819–824.

[BibTex]@InProceedings{Roetzer2018, author = {R\"otzer, F. and Aschauer, A. and Steinboeck, A. and Kugi, A.}, title = {A Computationally Efficient 3D Mathematical Model of a Molybdenum Batch-Reheating Furnace}, booktitle = {Proceedings of the 9th Vienna International Conference on Mathematical Modelling (MATHMOD)}, year = {2018}, month = {2}, pages = {819--824}, doi = {10.1016/j.ifacol.2018.04.015}, address = {Vienna, Austria}, }

- A. Aschauer, F. Roetzer, A. Steinboeck, and A. Kugi, An Efficient Algorithm for Scheduling a Flexible Job Shop with Blocking and No-Wait Constraints, in Proceedings of the 20th IFAC World Congress, Toulouse, France, 2017, pp. 12490-12495.

[BibTex]@InProceedings{Aschauer17, author = {Aschauer, A. and Roetzer, F. and Steinboeck, A. and Kugi, A.}, title = {An Efficient Algorithm for Scheduling a Flexible Job Shop with Blocking and No-Wait Constraints}, booktitle = {Proceedings of the 20th IFAC World Congress}, year = {2017}, volume = {50}, number = {1}, month = {7}, pages = {12490-12495}, doi = {10.1016/j.ifacol.2017.08.2056}, address = {Toulouse, France}, issn = {2405-8963}, }

Applications

- Automation of hot-rolling mills

- Industrial furnaces

- Time- and sequence optimization of production processes

Funding organisations

This research work is part of the EU project SemI40, which is funded by the programme ECSEL Joint Undertaking (Grant Agreement No. 692466) and the programme “IKT der Zukunft” (project number: 853343) of the Austrian Ministry for Transport, Innovation and Technology (bmvit) between May 2016 and April 2019. More information on IKT der Zukunft can be found at https://iktderzukunft.at/en/.

|

|

24.02.2017 Automated Handling of Highly Deformable Materials

Project focus

- Design and implementation of a prototypical device for the automated handling of limp materials

- Investigation and evaluation of various gripping technologies

- Mathematical modeling of tensile and bending behaviour of dry fibrous materials

- Active control of fibre tension during the handling process

Description

Since the 1980s fibre-reinforced composites (FRPs) were exclusively reserved for “high-end” applications in aerospace and sports industry. Driven by the possibility of stress optimized production and the enormous light-weight potential, there is an increasing interest in the use of fibre fabrics in other industries, such as automotive, machinery and plant manufacturing, etc. A widespread application across all industries, however, requires the reduction of the substantial additional manufacturing costs of composites compared to traditional materials while ensuring the required process reliability. As today’s FRPs are mainly produced in manual and semi-automated processes, future developments will move forward to a flexible, continuous industrialization of existing production processes. In this context, particularly, the (contour) flexible pick-up of dry or preimpregnated fibrous materials from the cutter table or storing and the subsequent controlled lay-up in a forming tool (mold) still represent a challenge for automated handling systems.

Although a number of mathematical models were developed since the 1930s for the prediction of structural changes of dry fibrous materials, these are, due to the model complexity, hardly used in the automated handling. Hence existing handling systems (mostly) operate in open-loop control (keyword: teach-in), i.e. forgoing any model-knowledge and feedback from a suitable sensor.

Experimental setup for the automated handling of limp materials.

Im Rahmen dieses Projekts wird prototypisch ein Handhabungssystem aufgebaut und das Potential der modernen modellbasierten Regelungstechnik für die Handhabung biegeschlaffer Materialien, wie sie die Halbzeuge darstellen, untersucht.

In this project, a prototype of a handling system is set up and the potential of modern model-based control to handle limp materials is examined.

The handling objects under investigation are non-crimp and woven fabric strips of varying structure, thickness and area density. Various gripping technologies are considered and evaluated regarding their suitability for particular fibrous materials. Basic tests are developed to identify the model parameters of the different fabrics in order to simulate the deformation behavior of these materials. The focus on the mathematical model is placed on the subsequent implementation of a model based control system, which is why a real-time prediction of the deformation behavior of a large class of materials has to be developed. Based on these models appropriate strategies for position and force control are designed. The active control of fibre tension during the handling ensures reliable pick-up, maintaining of the geometric definiteness during the handling process (no fiber displacement) and a wrinkle-free, material-friendly lay-up in or on complex shapes.

The subject is not only limited to the handling of carbon-fibre fabrics. The concepts are applicable to many other issues, such as the automated lamination of large vinyl sheets, textile handling, etc.

Videos

Selected publications

- S. Flixeder, Force-Based Cooperative Manipulation of Highly Deformable Materials, A. Kugi and K. Schlacher, Eds., Aachen: Shaker Verlag, 2017, vol. 36.

[BibTex]@Book{Flixeder17a, Title = {Force-Based Cooperative Manipulation of Highly Deformable Materials}, Author = {Flixeder, S.}, Editor = {A. Kugi and K. Schlacher}, Publisher = {Shaker Verlag}, Year = {2017}, Address = {Aachen}, Series = {Modellierung und Regelung komplexer dynamischer Systeme}, Volume = {36}, ISBN = {978-3-8440-5401-9}, Organization = {Institute f{\"u}r Automatisierungs- und Regelungstechnik (TU Wien) und Regelungstechnik und Prozessautomatisierung (JKU Linz)}, } - S. Flixeder, T. Glück, M. Böck, and A. Kugi, Model-Based Signal Processing for the Force Control of Biaxial Gantry Robots, in Proceedings of the 20th IFAC World Congress, Toulouse, France, 2017, p. 3208–3214.

[BibTex]@InProceedings{Flixeder17, author = {Flixeder, S. and Gl\"uck, T. and B\"ock, M. and Kugi, A.}, title = {Model-Based Signal Processing for the Force Control of Biaxial Gantry Robots}, booktitle = {Proceedings of the 20th IFAC World Congress}, year = {2017}, volume = {50}, number = {1}, month = {7}, pages = {3208--3214}, doi = {10.1016/j.ifacol.2017.08.439}, address = {Toulouse, France}, issn = {2405-8963}, } - S. Flixeder, T. Glück, and A. Kugi, Force-based cooperative handling and lay-up of deformable materials: Mechatronic design, modeling, and control of a demonstrator, Mechatronics, vol. 47, p. 246–261, 2017.

[BibTex]@Article{Flixeder16a, Title = {Force-based cooperative handling and lay-up of deformable materials: Mechatronic design, modeling, and control of a demonstrator}, Author = {Flixeder, S. and Gl\"uck, T. and Kugi, A.}, Journal = {Mechatronics}, Pages = {246--261}, Volume = {47}, Year = {2017}, Doi = {10.1016/j.mechatronics.2016.10.003}, ISSN = {0957-4158}, } - S. Flixeder, T. Glück, and A. Kugi, Modeling and Force Control for the Collaborative Manipulation of Deformable Strip-Like Materials, in Proceedings of the 7th IFAC Symposium on Mechatronic Systems & 15th Mechatronics Forum International Conference, Loughborough, UK, 2016, p. 95–102.

[BibTex] [Download]@InProceedings{Flixeder16, author = {Flixeder, S. and Gl\"uck, T. and Kugi, A.}, title = {Modeling and Force Control for the Collaborative Manipulation of Deformable Strip-Like Materials}, booktitle = {Proceedings of the 7th IFAC Symposium on Mechatronic Systems \& 15th Mechatronics Forum International Conference}, year = {2016}, volume = {49}, number = {21}, month = {9}, pages = {95--102}, doi = {10.1016/j.ifacol.2016.10.518}, address = {Loughborough, UK}, issn = {2405-8963}, } - S. Flixeder, T. Glück, M. Böck, R. Neumann, and A. Kugi, Kombinierte Pfad- und Nachgiebigkeitsregelung für ein Portalsystem mit experimenteller Validierung, in Tagungsband Mechatronik, Dortmund, Germany, 2015, p. 37–42.

[BibTex] [Download]@InProceedings{Flixeder15, author = {Flixeder, S. and Gl\"uck, T. and B\"ock, M. and Neumann, R. and Kugi, A.}, title = {{K}ombinierte {P}fad- und {N}achgiebigkeitsregelung f{\"u}r ein {P}ortalsystem mit experimenteller {V}alidierung}, booktitle = {Tagungsband Mechatronik}, year = {2015}, month = {3}, pages = {37--42}, address = {Dortmund, Germany}, } - S. Flixeder, T. Glück, M. Böck, and A. Kugi, Combined Path Following and Compliance Control with Application to a Biaxial Gantry Robot, in Proceedings of the IEEE Conference on Control Applications (CCA), Antibes, France, 2014, p. 796–801.

[BibTex] [Download]@InProceedings{Flixeder14, author = {Flixeder, Stefan and Gl\"uck, Tobias and B\"ock, Martin and Kugi, Andreas}, title = {Combined Path Following and Compliance Control with Application to a Biaxial Gantry Robot}, booktitle = {Proceedings of the IEEE Conference on Control Applications (CCA)}, year = {2014}, month = {10}, pages = {796--801}, doi = {10.1109/CCA.2014.6981438}, address = {Antibes, France}, } - S. Flixeder, T. Glück, M. Böck, and A. Kugi, Kombinierte Pfad- und Impedanzregelung für ein Portalsystem, in Tagungsband GMA-Fachausschuss 1.40 “Theoretische Verfahren der Regelungstechnik”, Anif/Salzburg, Austria, 2014, p. 128–154.

[BibTex]@InProceedings{Flixeder14a, author = {Flixeder, S. and Gl\"uck, T. and B\"ock, M. and Kugi, A.}, title = {Kombinierte {P}fad- und {I}mpedanzregelung f\"ur ein {P}ortalsystem}, booktitle = {Tagungsband GMA-Fachausschuss 1.40 "Theoretische Verfahren der Regelungstechnik"}, year = {2014}, month = {9}, pages = {128--154}, address = {Anif/Salzburg, Austria}, }

Applications

- Aerospace

- Automotive

- Machinery and plant manufacturing

Project partners and funding

08.06.2016 RALLI

Robotic Action-Language Learning through Interaction

Future social robots will need the ability to acquire new tasks and behaviors on the job both through observation and through natural language instruction, for robot designers cannot build in all environmental and task contingencies in typical application domains such as health care settings or people’s homes. In this project, we tackle the critical subproblem of learning new actions and their corresponding words by the artificial system observing how those actions are performed and expressed by humans. As a result, robots will not only understand action concepts, but will also be able to learn and execute actions, and talk about them. We propose to develop psychologically plausible observation and experimentation-based algorithms for action verb learning that are deeply integrated with natural language understanding and generation. The algorithms will allow the robot to observe and interpret human actions, and distill from them constitutive aspects such as the motion trajectories and involved objects. At the same time, the robot will also be able to parse a concomitant utterance describing the action and thus relate syntactic elements of the verbal description to semantic elements in the action representation. By aligning syntactic roles and semantic types, the robot then can build an association between verb phrase structure and action argument types. The outcome of the project will thus contribute an important, currently missing part for future social robots.

Partner

Funding

08.06.2016 ACROSSING

Advanced TeChnologies and PlatfoRm fOr Smarter ASsisted LivING

ACROSSING is an innovative research training network funded by the EU H2020 Marie Sklodowska-Curie Actions programme which aims to change the way millions of the older people in Europe live and maintain wellbeing. The project aims to make a critical contribution towards an open smart home technology infrastructure by interlinking disciplines from sensing technologies, context inferences and interaction and considering key principles of social impact, ethics, security and privacy.

Scientific target:

Develop technologies for smart-home based assisted living, including 4 specialised technology infrastructures, a shared experiment data repository and guidelines for smart home development based on best-practice demonstrators.

Training target:

Educate 15 ESRs in multi-disciplinary, transferable skills to become future research leaders in assisted living and create networks for future collaborations among partners.

Social target:

Increase European innovation capacity and competitiveness in smart home technology through the collaboration of industry and academia by integrating 4 ICT-driven application demonstrators as best-practice examples for the envisioned open SH technology infrastructure.

Partners

De Monfort University Leicester

Universität Passau

Austrian Institute of Technology

Noldus Information Technology

Philips

Ingeniería y Soluciones Informáticas (ISOIN)

CERTH – Centre for Research & Technology Hellas

Ulster University

Universidad Politécnica de Madrid (UPM)

Funding

Marie Sklodowska-Curie EU Framework for Research and Innovation Horizon 2020

08.06.2016 RoboFit

Im Projekt RoboFit besuchen uns Klassen (von Vorschulalter bis Oberstufe), um einen Vortrag über Robotik zu hören, bei einem kurzen Workshop sich an Roboternavigation zu versuchen, und um eine Demo unserer Roboter Romeo oder Pepper zu sehen. Außerdem stellen wir unser Wissen und unsere Erfahrung mit dem von uns entwickelten Schräge Roboter Konzept sowie mit der Durchführung von Benutzerstudien im Bereich Mensch-Roboter Interaktion dem Projekt zur Verfügung und betreuen vorwissenschaftliche Arbeiten im Bereich Robotik.

Projektteam

Prof. Markus Vincze ist der Öffentlichkeit als Robotikforscher bekannt. Zuletzt sorgten er und sein Team für Schlagzeilen mit HOBBIT, einem Roboter, der älteren Menschen ermöglichen soll, länger in ihrer eigenen Wohnung zu bleiben. Öffentlichkeitsprojekte wie z.B. die „Lange Nacht der Roboter“ oder die Mitarbeit bei der Roboterausstellung im Technischen Museum Wien sind wichtig, um der von Science-Fiction inspirierten breiten Masse zu zeigen, wie die Robotik in real aussieht und mit welchen Arbeiten sich derzeitige Roboterexperten wirklich beschäftigen.

Dr. techn. Lara Lammer ist eine kritische Denkerin, die verschiedene Ideen generiert, um die Probleme des 21. Jahrhunderts zu adressieren, um dann Lösungen mit anderen kreativen Köpfen zu konzipieren. Sie ist Projekleiterin, Kommunikatorin und Wissenschaftlerin in den Bereichen Robotik und Bildungsrobotik an der Technischen Universität Wien. Ihre wissenschaftliche Arbeit fokussiert sich auf holistische Konzepte und systemisches Denken. Sie hat das Konzept Schräge Roboter entwickelt und in verschiedenen Workshops (von Kindergarten bis Universität) angewandt, um junge Menschen in die Robotik aus der Perspektive der Produktentwicklung einzuführen.

Julian Angel, PhD, ist Experte in Mensch-Roboter Interaktion und entwickelt im EU Projekt ER4STEM (Educational Robotics for Science, Technology, Engineering and Mathematics) ein Framework und eine Plattform um diverse europäische Aktivitäten in der Bildungsrobotik unter einem Dach zu vereinen.

Clara Haider, Matthias Hirschmanner, Clemens Korner, Anvesh Nookala und Tobias Wolfmayr sind studentische Mitarbeiter, die das Projekt bei den Schulbesuchen, Workshops und Demos tatkräftig unterstützen.

Funding

FFG – Österreichische Forschungsförderungsgesellschaft

08.06.2015 AssistMe

AssistMe develops and evaluates during a user-centered multistage process innovative means of interaction for programming and usage of a robot-based assistive system.

Central topic is the integration of users in the concept development where the interaction paradigms are defined as well as in the evaluation stage of the developed technology. AssistMe examines the applicability of haptic (force feedback) interaction technology with means of machine vision respectively with methods from the field of spatial augmented reality. Together with two industrial companies universal applicability of the developed methodologeis will be evaluated in two entirely different application scenarios. One field of application is the assembly of automotive comustion engines while the other UseCase treats the machining (polishing) of casting modls.

Partners

Profactor (coordinator)

BMW Motoren GmbH

GPN GmbH

Funding

FFG – 7. Ausschreibung Produktion der Zukunft nat. Projekte

08.06.2015 ALOOF

Autonomous Learning of the Meaning of Objects

ALOOF will enable robots to tap into the ever-growing amount of knowledge available on the Web, by learning from there about the meaning of previously unseen objects, expressed in a form that makes them applicable when acting in situated environments. By searching the Web, robots will be able to learn about new objects, their specific properties, where they might be stored and so forth. To achieve this, robots need a mechanism for translating between the representations used in their real-world experience and those on the Web.

The goal of ALOOF is to significantly advance the ability of today’s autonomous systems to adapt to ever changing, dynamic real world environments by enabling them to learn about the meaning of objects from resources accessible through the Web.

In ALOOF we will explicitly focus on objects and the knowledge gaps a service robot will encounter about them.

The fundamental contribution of ALOOF will be to enable robots to translate between the representations they use in their situated experience and those on the Web.

Partners

- University of Rome La Sapienza, Department of Computer, Control and Management Engineering “Antonio Ruberti”

- ALCOR – Vision, Perception and Learning Robotics Lab

Rome, Italy

Prof. Barbara Caputo - School of Computer Science, University of Birmingham, Birmingham, United Kingdom

Dr. Nick Hawes - INRIA Sophia Antipolis, Wimmics Team, France

Sophia Antipolis

Dr. Fabien Gandon - Technische Universität Wien

Vienna, Austria

Prof. Markus Vincze

Funding

Chist-era, FWF

08.06.2015 ER4STEM

Educational Robotics for STEM

Many children lose their natural curiosity for how things function and interrelate to each other along the way into their lives as young adults. The Educational Robotics for STEM (ER4STEM) project aims to turn curious young children into young adults passionate about science and technology with a hands-on use case: robotics. The domain of robotics represents a multidisciplinary and highly innovative field encompassing physics, maths, informatics and even industrial design as well as social sciences. Moreover, due to various application domains, teamwork, creativity and entrepreneurial skills are required for the design, programming and innovative exploitation of robots and robotic services. Children are fascinated by such autonomous machines. This fascination and the variety of fields and topics covered make robotics a powerful idea to engage with. Young girls as well as boys can easily connect robots to their personal interests and share their ideas through these tangible artefacts.

ER4STEM will refine, unify and enhance current European approaches to STEM education through robotics in one open operational and conceptual framework. The concept is founded on three important pillars of constructionism: 1. engaging with powerful ideas, 2. building on personal interests, and 3. learning through making (or presenting ideas with tangible artefacts). The ER4STEM framework will coherently offer students aged 7 to 18 as well as their educators different perspectives and approaches to find their interests and strengths in robotics to pursue STEM careers through robotics and semi-autonomous smart devices. At the same time students will learn about technology (e.g. circuits), about a domain (e.g. math) and acquire skills (e.g. collaborating, coding). Innovative approaches will be developed to achieve an integrated and consistent concept that picks children up at different ages, beginning in primary school and accompany them until graduation from secondary school.

Partners

- European Software Institute Center Eastern Europe

- Practical Robotics Institute Austria

- University of Athens Educational Technology Lab

- AcrossLimits

- Cardiff University School of Social Science

- Certicon

Funding

- EU H2020-SEAC-2014-1