Modeling, observer design, and control of continuous slab reheating furnaces

Project focus

- Modeling and parameter identification of continuous reheating furnaces

- Observer design for non-measurable system quantities

- Model-based control and optimization of nonlinear dynamical systems

- Nonlinear model predictive control of product temperatures

Description

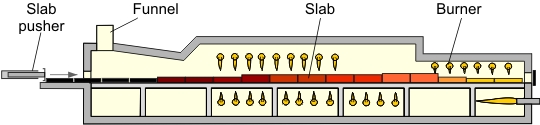

Continuous reheating furnaces are used in the steel industry to reheat slabs (steel blocks weighing up to 40 tons) before they are rolled out in the subsequent rolling process. During the energy- and cost-intensive reheating process, the slabs are lined up and continuously moved through the gas- or oil-fired furnace. The energy consumption of a medium-sized slab reheating furnace is approximately equal to that of a town with 25000 inhabitants. The desired product temperature for the rolling process is between 1050 and 1200 degrees Celsius. It is vital for the product quality that this temperature is accurately reached.

Continuous slab reheating furnace.

The total thermal energy supply of the system is computed by means of a stoichiometric analysis of the combustion process. Convection and especially thermal radiation transfer the heat to the slabs. Based on a geometric discretization of the furnace volume, mass, energy, and radiation balances are considered in the mathematical model. The nonlinear dynamical system has a switched structure because the slabs are discontinuously moved forward.

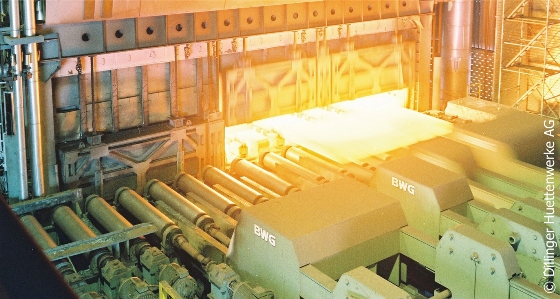

A hot slab is discharged from the furnace, Copyright: Dillinger Hüttenwerke AG.

The temperature field inside the slabs cannot be measured. It is therefore estimated by state observers (e.g., extended or unscented Kalman filters) using mathematical models that can be evaluated in real-time. A nonlinear model predictive multi-input multi-output controller regulates the local furnace temperatures by means of the fuel supply to the burners. The controller minimizes the energy consumption and ensures that the slabs accurately reach their desired temperatures. Input and state constraints and the diverse product range (different product geometries and desired temperatures) are a challenge for the controller. Another problem is that the sequence of the slabs and their processing times are prescribed by upstream or downstream process steps. Nonlinear model predictive control is used for the high-level multi-input multi-output control task.

The developed control system has been installed on several industrial slab reheating furnaces. Measurements made with an instrumented test slab demonstrate that the slabs are accurately reheated. Compared to conventional furnace control concepts, the system saves a considerable amount of energy, curbs CO2 emissions and thus makes the process more ecologically desirable.

Selected publications

- A. Steinboeck and A. Kugi, Optimized pacing of continuous reheating furnaces, in Proceedings of European Control Conference ECC 2013, Zürich, Switzerland, 2013, p. 4454 – 4459.

[BibTex]@InProceedings{Steinboeck13b, author = {A. Steinboeck and A. Kugi}, title = {{Optimized pacing of continuous reheating furnaces}}, booktitle = {Proceedings of European Control Conference ECC 2013}, year = {2013}, month = {7}, pages = {4454 -- 4459}, url = {http://ieeexplore.ieee.org/xpl/articleDetails.jsp?tp=&arnumber=6669132}, address = {Z\"{u}rich, Switzerland}, } - A. Steinboeck, D. Wild, and A. Kugi, Energy-Efficient Control of Continuous Reheating Furnaces, in Proceedings of 15th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral & Metal Processing, San Diego, USA, 2013, p. 359 – 364.

[BibTex]@InProceedings{Steinbock13, author = {A. Steinboeck and D. Wild and A. Kugi}, title = {{Energy-Efficient Control of Continuous Reheating Furnaces}}, booktitle = {Proceedings of 15th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral \& Metal Processing}, year = {2013}, month = {8}, pages = {359 -- 364}, doi = {10.3182/20130825-4-US-2038.00007}, address = {San Diego, USA}, } - A. Steinboeck, D. Wild, and A. Kugi, Nonlinear model predictive control of a continuous slab reheating furnace, Control Engineering Practice, vol. 21, iss. 4, p. 495–508, 2013.

[BibTex] [Download]@Article{Steinboeck13, Title = {{Nonlinear model predictive control of a continuous slab reheating furnace}}, Author = {A. Steinboeck and D. Wild and A. Kugi}, Journal = {Control Engineering Practice}, Pages = {495--508}, Volume = {21}, Year = {2013}, Number = {4}, Doi = {10.1016/j.conengprac.2012.11.012}, } - A. Steinboeck, D. Wild, and A. Kugi, Optimal Trajectory Planning and Control of a Continuous Slab Reheating Furnace, in Proceedings of the IFAC Workshop on Automation in the Mining, Mineral and Metal Industries, Gifu, Japan, 2012, p. 169 – 174.

[BibTex]@InProceedings{Steinbock12, author = {A. Steinboeck and D. Wild and A. Kugi}, title = {{O}ptimal {T}rajectory {P}lanning and {C}ontrol of a {C}ontinuous {S}lab {R}eheating {F}urnace}, booktitle = {Proceedings of the IFAC Workshop on Automation in the Mining, Mineral and Metal Industries}, year = {2012}, month = {9}, pages = {169 -- 174}, address = {Gifu, Japan}, } - A. Steinboeck, K. Graichen, and A. Kugi, Dynamic Optimization of a Slab Reheating Furnace with consistent Approximation of Control Variables, IEEE Transactions on Control Systems Technology, vol. 19, p. 1444–1456, 2011.

[BibTex] [Download]@Article{Steinboeck11a, Title = {{Dynamic Optimization of a Slab Reheating Furnace with consistent Approximation of Control Variables}}, Author = {A. Steinboeck and K. Graichen and A. Kugi}, Journal = {IEEE Transactions on Control Systems Technology}, Pages = {1444--1456}, Volume = {19}, Year = {2011}, Doi = {10.1109/TCST.2010.2087379}, } - A. Steinboeck, K. Graichen, D. Wild, T. Kiefer, and A. Kugi, Model-based trajectory planning, optimization, and open-loop control of a continuous slab reheating furnace, Journal of Process Control, vol. 21, iss. 2, p. 279–292, 2011.

[BibTex] [Download]@Article{Steinbock11a, Title = {Model-based trajectory planning, optimization, and open-loop control of a continuous slab reheating furnace}, Author = {A. Steinboeck and K. Graichen and D. Wild and T. Kiefer and A. Kugi}, Journal = {Journal of Process Control}, Pages = {279--292}, Volume = {21}, Year = {2011}, Number = {2}, Doi = {10.1016/j.jprocont.2010.08.004}, } - A. Steinboeck, D. Wild, and A. Kugi, Feedback Tracking Control of Continuous Reheating Furnances, in Proceedings of the 18th IFAC World Congress, Milano, Italia, 2011, p. 11744–11749.

[BibTex]@InProceedings{Steinbock11, author = {A. Steinboeck and D. Wild and A. Kugi}, title = {{F}eedback {T}racking {C}ontrol of {C}ontinuous {R}eheating {F}urnances}, booktitle = {Proceedings of the 18th IFAC World Congress}, year = {2011}, month = {8}, pages = {11744--11749}, doi = {10.3182/20110828-6-IT-1002.01639}, address = {Milano, Italia}, } - A. Steinboeck, D. Wild, T. Kiefer, and A. Kugi, A mathematical model of a slab reheating furnace with radiative heat transfer and non-participating gaseous media, International Journal of Heat and Mass Transfer, vol. 53, pp. 5933-5946, 2010.

[BibTex] [Download]@Article{Steinbock10, Title = {A mathematical model of a slab reheating furnace with radiative heat transfer and non-participating gaseous media}, Author = {A. Steinboeck and D. Wild and T. Kiefer and A. Kugi}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {5933-5946}, Volume = {53}, Year = {2010}, Doi = {10.1016/j.ijheatmasstransfer.2010.07.029}, } - D. Wild, T. Meurer, and A. Kugi, Modelling and Experimental Model Validation for a Pusher-type Reheating Furnace, Mathematical and Computer Modelling of Dynamical Systems, vol. 15, iss. 3, p. 209–232, 2009.

[BibTex] [Download]@Article{Wild09, Title = {Modelling and Experimental Model Validation for a Pusher-type Reheating Furnace}, Author = {D. Wild and T. Meurer and A. Kugi}, Journal = {Mathematical and Computer Modelling of Dynamical Systems}, Pages = {209--232}, Volume = {15}, Year = {2009}, Number = {3}, Doi = {10.1080/13873950902927683}, }

Applications

- Automation of rolling mills

- Industrial furnaces

- Continuous production processes