24.08.2017 Modellierung und Regelung hydraulischer Antriebssysteme

Projektschwerpunkte

- Mathematische Modellierung von hydraulischen Systemen, insbesondere Axialkolbenmaschinen

- Adaptive, nichtlineare Regelung von Axialkolbenmaschinen

- Optimale, modell-prädiktive Regelungsstrategien für Axialkolbenmaschinen

- Anwendung für einen hydraulischen Hybridantrieb

Beschreibung

Hydraulische Antriebe weisen eine große Verbreitung in vielen industriellen Anwendungen auf. Dies liegt an der hohen Leistungsdichte bei geringem Bauraum und Gewicht. Die Regelung von hydraulischen Antrieben erfolgt dabei meist mit Hilfe von Ventilen, womit eine sehr hohe Dynamik erreichbar ist. Der wesentliche Nachteil bei einer Ventilsteuerung besteht jedoch in den relativ großen energetischen Verlusten.

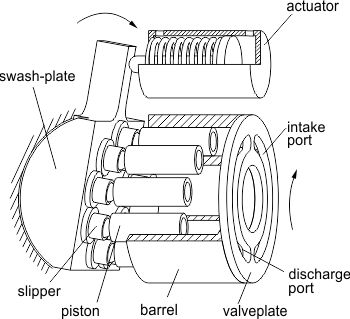

Um die energetische Effizienz zu erhöhen werden in diesem Forschungsprojekt verstellbare Pumpen bzw. Motoren betrachtet. Insbesondere werden Axialkolbenmaschinen in Schrägscheibenbauweise betrachtet, die eine kontinuierliche und relativ schnelle Veränderung des geförderten Volumenstroms durch Verdrehung der Schwenkscheibe (swash-plate) erlauben, siehe Abb. 1. In dieser Forschungskooperation mit der Firma Robert Bosch GmbH werden optimale Regelungsstrategien für den Schwenkwinkel entwickelt, die die Basis für eine Regelung des Volumenstroms, des Drucks und des mechanischen Moments der Maschine bilden.

Prinzipbild einer Axialkolbenmaschine in Schrägscheibenbauweise

Die Herausforderung bei der Entwicklung einer Regelungsstrategie sind dabei die ausgeprägten Nichtlinearitäten und die Beschränkungen des Systems, sowie schnell veränderliche externe Lasten. Für Anwendungen mit schnell veränderlichen Lasten wurde eine nichtlineare adaptive Regelungsstrategie mit zugehöriger Schätzung der Last entwickelt. Um eine systematische Berücksichtigung der Nichtlinearitäten und Beschränkungen des Systems zu ermöglichen, werden nichtlineare, modellprädiktive Regelungsstrategien entwickelt. Die dazu notwendigen internen, nicht messbaren Zustände des Systems werden durch geeignete nichtlineare Beobachterkonzepte ermittelt. Es konnte in diesem Forschungsprojekt bereits gezeigt werden, dass eine echtzeitfähige Implementierung eines solchen Regelungskonzeptes auf einer industriellen Echtzeithardware mit einer Abtastzeit von 1 ms möglich ist.

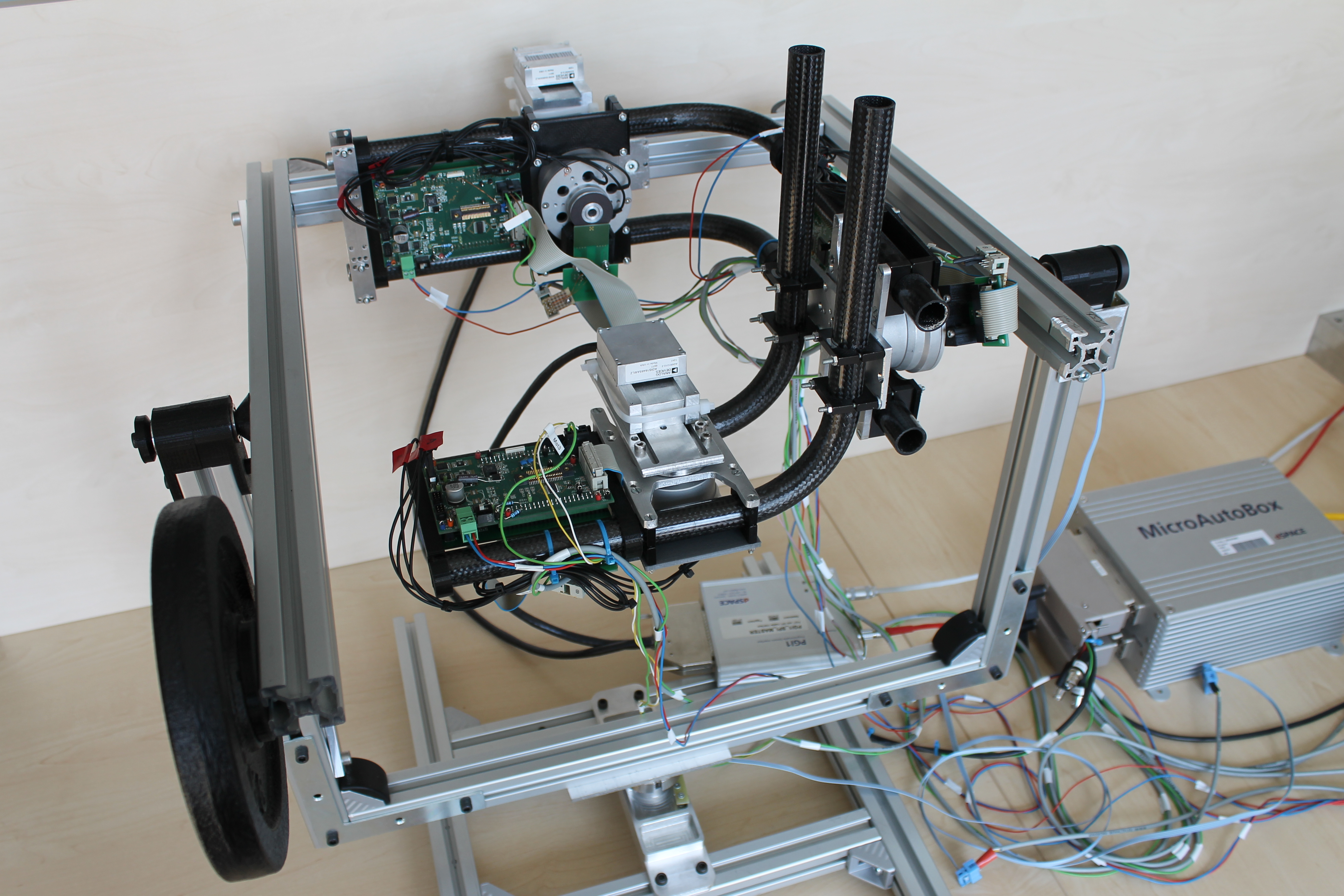

Prüfstand zum Test der adaptiven nichtlinearen Regelungsstrategie

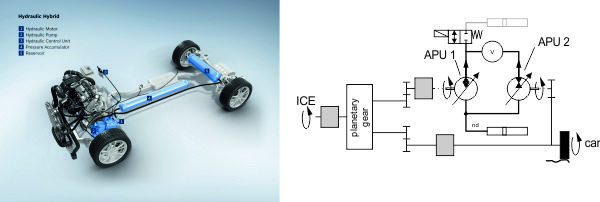

Basierend auf der optimalen Schwenkwinkelregelung werden erweiterte Regelungsstrategien z.B. für die Regelung der Drehzahl der Axialkolbenmaschine entwickelt. Eine mögliche Anwendung, die im Rahmen des gemeinsamen Forschungsprojektes mit der Firma Robert Bosch GmbH betrachtet wurde, ist ein hydraulisches Hybridsystem, siehe Abb. 3. Dieses System besteht im Wesentlichen aus einem Verbrennungskraftmotor (ICE), sowie einem hydraulischen Antriebsstrang, der zwei Axialkolbenmaschinen (APU) aufweist. Um die beim Bremsen des Fahrzeugs anfallende Energie zu speichern, wird Öl in einen Kolbenspeicher gefördert. Für dieses System wurden im Rahmen der Forschungsarbeiten mathematische Modelle des Systems entwickelt und Schätzstrategien für den Ladezustand des Kolbenspeichers erforscht. Weiterhin wurde für gewisse Betriebsfälle eine optimale (modell-prädiktive) Regelungsstrategie entwickelt, die ein bestmögliches Folgen des Fahrerwunsches bei gleichzeitiger Minimierung der Verluste des Systems ermöglicht.

Prinzipbild eines hydraulische Hybridantriebs (c) Robert Bosch GmbH

Ausgewählte Publikationen

- P. Zeman, W. Kemmetmüller, and A. Kugi, Nonlinear Model Predictive Control of Axial Piston Pumps, Journal of Dynamic Systems, Measurement, and Control, vol. 139, iss. 8, p. 081008-1–081008-11, 2017.

[BibTex]@Article{Zeman17, Title = {Nonlinear Model Predictive Control of Axial Piston Pumps}, Author = {Zeman, P. and Kemmetm\"uller, W. and Kugi, A.}, Journal = {Journal of Dynamic Systems, Measurement, and Control}, Pages = {081008-1--081008-11}, Volume = {139}, Year = {2017}, Number = {8}, Doi = {10.1115/1.4035608}, ISSN = {0022-0434}, } - P. Zeman, W. Kemmetmüller, and A. Kugi, Energy-efficient Constrained Control of a Hydrostatic Power Split Drive, in Proceedings of the 20th IFAC World Congress, Toulouse, France, 2017, p. 4775–4780.

[BibTex]@InProceedings{Zeman17a, author = {Zeman, P. and Kemmetm\"uller, W. and Kugi, A.}, title = {Energy-efficient Constrained Control of a Hydrostatic Power Split Drive}, booktitle = {Proceedings of the 20th IFAC World Congress}, year = {2017}, volume = {50}, number = {1}, month = {7}, pages = {4775--4780}, doi = {10.1016/j.ifacol.2017.08.959}, address = {Toulouse, France}, issn = {2405-8963}, } - A. Pfeffer, T. Glück, W. Kemmetmüller, and A. Kugi, Mathematical modelling of a hydraulic accumulator for hydraulic hybrid drives, Mathematical and Computer Modelling of Dynamical Systems, vol. 22, iss. 5, p. 397–411, 2016.

[BibTex] [Download]@Article{Pfeffer16, Title = {Mathematical modelling of a hydraulic accumulator for hydraulic hybrid drives}, Author = {Pfeffer, A. and Gl\"uck, T. and Kemmetm\"uller, Wolfgang and Kugi, Andreas}, Journal = {Mathematical and Computer Modelling of Dynamical Systems}, Pages = {397--411}, Volume = {22}, Year = {2016}, Number = {5}, Doi = {10.1080/13873954.2016.1174716}, ISSN = {1387-3954}, } - P. Zeman, W. Kemmetmüller, and A. Kugi, Model Predictive Speed Control of Axial Piston Motors, in Proceedings of the 10th IFAC Symposium on Nonlinear Control Systems (NOLCOS 2016), Monterey, USA, 2016, p. 772–777.

[BibTex]@InProceedings{Zeman16, author = {Zeman, P. and Kemmetm\"uller, W. and Kugi, A.}, title = {Model Predictive Speed Control of Axial Piston Motors}, booktitle = {Proceedings of the 10th IFAC Symposium on Nonlinear Control Systems (NOLCOS 2016)}, year = {2016}, volume = {49}, number = {18}, month = {8}, pages = {772--777}, doi = {10.1016/j.ifacol.2016.10.259}, address = {Monterey, USA}, issn = {2405-8963}, } - A. Pfeffer, T. Glück, W. Kemmetmüller, and A. Kugi, State of Charge Estimator Design for a Hydro-Pneumatic Accumulator, Journal of Dynamic Systems, Measurement, and Control, vol. 137, iss. 6, p. 061014:1–061014:9, 2015.

[BibTex]@Article{Pfeffer15, Title = {State of Charge Estimator Design for a Hydro-Pneumatic Accumulator}, Author = {Pfeffer, A. and Gl\"uck, T. and Kemmetm\"uller, W. and Kugi, A.}, Journal = {Journal of Dynamic Systems, Measurement, and Control}, Pages = {061014:1--061014:9}, Volume = {137}, Year = {2015}, Number = {6}, Doi = {10.1115/1.4029407}, } - P. Zeman, W. Kemmetmüller, and A. Kugi, Mathematical Modeling and Analysis of a Hydrostatic Drive Train, in Proceedings of the 8th Vienna International Conference on Mathematical Modelling (MATHMOD), Vienna, Austria, 2015, p. 508–513.

[BibTex]@InProceedings{Zeman15, author = {Zeman, P. and Kemmetm\"uller, W. and Kugi, A.}, title = {Mathematical Modeling and Analysis of a Hydrostatic Drive Train}, booktitle = {Proceedings of the 8th Vienna International Conference on Mathematical Modelling (MATHMOD)}, year = {2015}, month = {2}, pages = {508--513}, doi = {10.1016/j.ifacol.2015.05.064}, address = {Vienna, Austria}, } - W. Kemmetmüller, F. Fuchshumer, and A. Kugi, Nonlinear pressure control of self-supplied variable displacement axial piston pumps, Control Engineering Practice, vol. 18, p. 84–93, 2010.

[BibTex] [Download]@Article{Kemmetmuller10, Title = {Nonlinear pressure control of self-supplied variable displacement axial piston pumps}, Author = {W. Kemmetm{\"u}ller and F. Fuchshumer and A. Kugi}, Journal = {Control Engineering Practice}, Pages = {84--93}, Volume = {18}, Year = {2010}, Doi = {10.1016/j.conengprac.2009.09.006}, }

Projektpartner

- Robert Bosch GmbH

- Entwicklung effizienter Modelle zur Beschreibung der Strömung in Druckrohrleitungen

- Entwicklung skalierbarer, physikalisch-basierter digitaler Zwillinge von Pumpspeicherkraftwerken

- Entwurf optimaler (modell-prädiktiver) Regelungsstrategien

- Untersuchung der Beobachtung von nicht messbaren Größen

- J. -F. Mennemann, L. Marko, J. Schmidt, W. Kemmetmüller, and A. Kugi, The spectral element method as an efficient tool for transient simulations of hydraulic systems, Applied Mathematical Modelling, vol. 54, p. 627–647, 2018.

[BibTex] [Download]@Article{Mennemann2018, author = {Mennemann, J.-F. and Marko, L. and Schmidt, J. and Kemmetm{\"u}ller, W. and Kugi, A.}, title = {{The spectral element method as an efficient tool for transient simulations of hydraulic systems}}, doi = {10.1016/j.apm.2017.10.010}, issn = {0307-904X}, pages = {627--647}, volume = {54}, journal = {Applied Mathematical Modelling}, year = {2018}, } - J. Schmidt, W. Kemmetmüller, and A. Kugi, Modeling and static optimization of a variable speed pumped storage power plant, Renewable Energy, vol. 111, p. 38–51, 2017.

[BibTex] [Download]@Article{Schmidt17, Title = {Modeling and static optimization of a variable speed pumped storage power plant}, Author = {Schmidt, J. and Kemmetm\"uller, W. and Kugi, A.}, Journal = {Renewable Energy}, Pages = {38--51}, Volume = {111}, Year = {2017}, Doi = {10.1016/j.renene.2017.03.055}, ISSN = {0960-1481}, } - J. -F. Mennemann, J. Schmidt, W. Kemmetmüller, and A. Kugi, Simulation von Welleneffekten in Pumpspeicherkraftwerken mit Hilfe der Spektral-Element-Methode, at – Automatisierungstechnik, vol. 64, iss. 8, p. 681–695, 2016.

[BibTex]@Article{Mennemann16, Title = {{Simulation von Welleneffekten in Pumpspeicherkraftwerken mit Hilfe der Spektral-Element-Methode}}, Author = {Mennemann, J.-F. and Schmidt, J. and Kemmetm{\"u}ller, W. and Kugi, A.}, Journal = {at -- Automatisierungstechnik}, Pages = {681--695}, Volume = {64}, Year = {2016}, Number = {8}, Doi = {10.1515/auto-2016-0061}, ISSN = {0178-2312}, } - J. Mennemann, J. Schmidt, W. Kemmetmüller, and A. Kugi, Anwendung der Spectral-Penalty-Methode zur effizienten Diskretisierung der Massen- und Impulsbilanzgleichungen in Rohrleitungssystemen von Pumpspeicherkraftwerken, in Tagungsband GMA-Fachausschuss 1.30 „Modellbildung, Identifikation und Simulation in der Automatisierungstechnik“, Anif/Salzburg, Austria, 2015, p. 56–95.

[BibTex]@InProceedings{Mennemann15, author = {Mennemann, Jan-Frederik and Schmidt, J. and Kemmetm\"uller, W. and Kugi, A.}, title = {{Anwendung der Spectral-Penalty-Methode zur effizienten Diskretisierung der Massen- und Impulsbilanzgleichungen in Rohrleitungssystemen von Pumpspeicherkraftwerken}}, booktitle = {Tagungsband GMA-Fachausschuss 1.30 "Modellbildung, Identifikation und Simulation in der Automatisierungstechnik"}, year = {2015}, month = {9}, isbn = {978-3-9815012-9-2}, pages = {56--95}, address = {Anif/Salzburg, Austria}, } - J. Schmidt, W. Kemmetmüller, and A. Kugi, Modellierung und Analyse eines Pumpspeicherkraftwerks mit drehzahlvariablem Generator, in Tagungsband GMA-Fachausschuss 1.30 „Modellbildung, Identifikation und Simulation in der Automatisierungstechnik“, Anif/Salzburg, Austria, 2014, p. 38–68.

[BibTex]@InProceedings{Schmidt14, author = {Schmidt, J. and Kemmetm\"uller, W. and Kugi, A.}, title = {Modellierung und {A}nalyse eines {P}umpspeicherkraftwerks mit drehzahlvariablem {G}enerator}, booktitle = {Tagungsband GMA-Fachausschuss 1.30 "Modellbildung, Identifikation und Simulation in der Automatisierungstechnik"}, year = {2014}, month = {9}, pages = {38--68}, address = {Anif/Salzburg, Austria}, } - L. Marko, J. -F. Mennemann, L. Jadachowski, W. Kemmetmüller, and A. Kugi, Early- and late-lumping observer designs for long hydraulic pipelines: Application to pumped-storage power plants, Int. Journal of Robust and Nonlinear Control, vol. 28, iss. 7, p. 2759–2779, 2018.

[BibTex]@Article{Marko2018, author = {Marko, L. and Mennemann, J.-F. and Jadachowski, L. and Kemmetm{\"u}ller, W. and Kugi, A.}, title = {{Early- and late-lumping observer designs for long hydraulic pipelines: Application to pumped-storage power plants}}, doi = {10.1002/rnc.4049}, issn = {1099-1239}, number = {7}, pages = {2759--2779}, volume = {28}, journal = {Int. Journal of Robust and Nonlinear Control}, year = {2018}, } - Kontinuumsmechanische Modellierung von elektrorheologischen Flüssigkeiten

- Entwicklung und Regelung von elektrorheologischen Ventilen

- Entwicklung, Modellierung und Regelung von semi-aktiven elektrorheologischen Radaufhängungssystemen

- Umsetzung und Test an Prüfstanden bzw. an Testfahrzeugen

- W. Kemmetmüller, K. Holzmann, A. Kugi, and M. Stork, Electrorheological Semiactive Shock Isolation Platform for Naval Applications, IEEE/ASME Transactions on Mechatronics, vol. 18, iss. 5, p. 1437–1447, 2013.

[BibTex] [Download]@Article{Kemmetmuller13a, Title = {{{E}lectrorheological {S}emiactive {S}hock {I}solation {P}latform for {N}aval {A}pplications}}, Author = {W. Kemmetm{\"u}ller and K. Holzmann and A. Kugi and M. Stork}, Journal = {IEEE/ASME Transactions on Mechatronics}, Pages = {1437--1447}, Volume = {18}, Year = {2013}, Number = {5}, Doi = {10.1109/TMECH.2012.2203456}, } - M. Kamelreiter, W. Kemmetmüller, and A. Kugi, Digitally controlled electrorheological valves and their application in vehicle dampers, Mechatronics, vol. 22, iss. 5, p. 629–638, 2012.

[BibTex] [Download]@Article{Kamelreiter12, Title = {{Digitally controlled electrorheological valves and their application in vehicle dampers}}, Author = {M. Kamelreiter and W. Kemmetm\"uller and A. Kugi}, Journal = {Mechatronics}, Pages = {629--638}, Volume = {22}, Year = {2012}, Number = {5}, Doi = {10.1016/j.mechatronics.2012.02.002}, } - M. Kamelreiter, W. Kemmetmüller, and A. Kugi, Digitale Ansteuerung elektrorheologischer Ventile und deren Anwendung in einem Fahrzeugdämpfer, in Tagungsband Mechatronik 2011 Dresden, Dresden, Germany, 2011, p. 37–42.

[BibTex]@InProceedings{Kamelreiter11, author = {M. Kamelreiter and W. Kemmetm\"uller and A. Kugi}, title = {{D}igitale {A}nsteuerung elektrorheologischer {V}entile und deren {A}nwendung in einem {F}ahrzeugd\"ampfer}, booktitle = {Tagungsband Mechatronik 2011 Dresden}, year = {2011}, month = {3}, pages = {37--42}, address = {Dresden, Germany}, } - M. Kamelreiter, W. Kemmetmüller, and A. Kugi, Digital Control of Electrorheological Valves, in Proceedings of the 5th IFAC Symposium on Mechatronic Systems, Boston, USA, 2010, p. 640–645.

[BibTex] [Download]@InProceedings{Kamelreiter10, author = {M. Kamelreiter and W. Kemmetm{\"u}ller and A. Kugi}, title = {Digital Control of Electrorheological Valves}, booktitle = {Proceedings of the 5th IFAC Symposium on Mechatronic Systems}, year = {2010}, month = {9}, pages = {640--645}, doi = {10.3182/20100913-3-US-2015.00075}, address = {Boston, USA}, } - K. Holzmann, W. Kemmetmüller, A. Kugi, M. Stork, H. Rosenfeldt, and S. Schneider, Modeling and control of an off-road truck using electrorheological dampers, Journal of Physics: Conference Series, vol. 149, 012011, 2009.

[BibTex] [Download]@Article{Holzmann09, Title = {Modeling and control of an off-road truck using electrorheological dampers}, Author = {K. Holzmann and W. Kemmetm{\"u}ller and A. Kugi and M. Stork and H. Rosenfeldt and S. Schneider}, Journal = {Journal of Physics: Conference Series}, Volume = {149, 012011}, Year = {2009}, Doi = {10.1088/1742-6596/149/1/012011}, } - M. Kamelreiter, W. Kemmetmüller, A. Kugi, K. Holzmann, and M. Stork, Modellierung und Regelung eines Kleintransporters mit semi-aktiver Radaufhängung basierend auf elektrorheo-logischen Dämpfern, in Mechatronik 2009, Wiesloch, Germany, 2009, p. 413–420.

[BibTex]@InProceedings{Kamelreiter09, author = {M. Kamelreiter and W. Kemmetm{\"u}ller and A. Kugi and K. Holzmann and M. Stork}, title = {Modellierung und {R}egelung eines {K}leintransporters mit semi-aktiver {R}adaufh{\"a}ngung basierend auf elektrorheo-logischen {D}{\"a}mpfern}, booktitle = {Mechatronik 2009}, year = {2009}, month = {5}, pages = {413--420}, address = {Wiesloch, Germany}, } - K. Holzmann, W. Kemmetmüller, A. Kugi, M. Stork, H. Rosenfeldt, and S. Schneider, Modeling and control of an off-road truck using electrorheological dampers, in Proceedings 11th Conference on Electrorheological Fluids and Magnetorheological Suspensions, Dresden, Germany, 2008.

[BibTex]@InProceedings{Holzmann08, author = {K. Holzmann and W. Kemmetm{\"u}ller and A. Kugi and M. Stork and H. Rosenfeldt and S. Schneider}, title = {Modeling and control of an off-road truck using electrorheological dampers}, booktitle = {Proceedings 11th Conference on Electrorheological Fluids and Magnetorheological Suspensions}, year = {2008}, month = {8}, doi = {10.1088/1742-6596/149/1/012011}, address = {Dresden, Germany}, } - Fludicon GmbH

- Optimierung des Aufbaus (Aktoren, Sensoren) der Kamerastabilisierungsplattform

- Schätzung der Kameraorientierung mittels redundanter Inertialsensorik

- Entwurf einer nichtlinearen Regelungsstrategie für die Kameraorientierung

- Prototypische Implementierung und Test

- F. Königseder, W. Kemmetmüller, and A. Kugi, Attitude Estimation Using Redundant Inertial Measurement Units for the Control of a Camera Stabilization Platform, IEEE Transactions on Control Systems Technology, vol. 24, iss. 5, p. 1837–1844, 2016.

[BibTex] [Download]@Article{Koenigseder16, Title = {Attitude Estimation Using Redundant Inertial Measurement Units for the Control of a Camera Stabilization Platform}, Author = {K{\"o}nigseder, F. and Kemmetm{\"u}ller, W. and Kugi, A.}, Journal = {IEEE Transactions on Control Systems Technology}, Pages = {1837--1844}, Volume = {24}, Year = {2016}, Number = {5}, Doi = {10.1109/TCST.2015.2510324}, ISSN = {1063-6536}, } - F. Königseder, W. Kemmetmüller, and A. Kugi, Modellierung und Regelung einer tragbaren Kamerastabilisierungsplattform, in Tagungsband Mechatronik 2013, Aachen, Germany, 2013, p. 99–104.

[BibTex]@InProceedings{Konigseder13, author = {F. K{\"o}nigseder and W. Kemmetm{\"u}ller and A. Kugi}, title = {{{M}odellierung und {R}egelung einer tragbaren {K}amerastabilisierungsplattform}}, booktitle = {Tagungsband Mechatronik 2013}, year = {2013}, month = {3}, pages = {99--104}, address = {Aachen, Germany}, } - Modellierung, Modellverifikation und Systemanalyse

- Beobachter- bzw. Schätzerentwurf zur Online- und Offline-Bestimmung der Kabelkapazität

- Entwurf eines echtzeitfähigen Regelungskonzepts

- Optimierung der Systemparameter

- Umsetzung der Regelungs- und Schätzkonzepte am Prototyp

- S. Eberharter, W. Kemmetmüller, and A. Kugi, Analysis and System Optimization of a Very Low Frequency High-Voltage Test System, in Proceedings of the 7th IFAC Symposium on Mechatronic Systems & 15th Mechatronics Forum International Conference, Loughborough, UK, 2016, p. 294–300.

[BibTex]@InProceedings{Eberharter16a, author = {Eberharter, S. and Kemmetm\"uller, W. and Kugi, A.}, title = {Analysis and System Optimization of a Very Low Frequency High-Voltage Test System}, booktitle = {Proceedings of the 7th IFAC Symposium on Mechatronic Systems \& 15th Mechatronics Forum International Conference}, year = {2016}, volume = {49}, number = {21}, month = {9}, pages = {294--300}, doi = {10.1016/j.ifacol.2016.10.570}, address = {Loughborough, UK}, issn = {2405-8963}, } - W. Kemmetmüller, S. Eberharter, and A. Kugi, Controller design and experimental validation of a very low frequency high-voltage test system, Control Engineering Practice, vol. 37, p. 32–42, 2015.

[BibTex] [Download]@Article{Kemmetmueller15, Title = {Controller design and experimental validation of a very low frequency high-voltage test system}, Author = {Kemmetm\"uller, W. and Eberharter, S. and Kugi, A.}, Journal = {Control Engineering Practice}, Pages = {32--42}, Volume = {37}, Year = {2015}, Doi = {10.1016/j.conengprac.2014.12.011}, } - S. Eberharter, W. Kemmetmüller, and A. Kugi, Mathematical Modeling and Analysis of a Very Low Frequency HV Test System, IEEE Transactions on Power Electronics, vol. 29, iss. 11, p. 5784–5794, 2014.

[BibTex] [Download]@Article{Eberharter14, Title = {Mathematical Modeling and Analysis of a Very Low Frequency {HV} Test System}, Author = {Eberharter, S. and Kemmetm\"uller, W. and Kugi, A.}, Journal = {IEEE Transactions on Power Electronics}, Pages = {5784--5794}, Volume = {29}, Year = {2014}, Number = {11}, Doi = {10.1109/TPEL.2014.2299293}, } - W. Kemmetmüller, S. Eberharter, and A. Kugi, Quasi Optimal Feedforward Control of a Very Low Frequency High Voltage Test System, in Proceedings of the 19th IFAC World Congress, Cape Town, South Africa, 2014, p. 11623–11628.

[BibTex]@InProceedings{Kemmetmueller14a, author = {Kemmetm\"uller, W. and Eberharter, S. and Kugi, A.}, title = {Quasi Optimal Feedforward Control of a Very Low Frequency High Voltage Test System}, booktitle = {Proceedings of the 19th IFAC World Congress}, year = {2014}, month = {8}, pages = {11623--11628}, doi = {10.3182/20140824-6-ZA-1003.00356}, address = {Cape Town, South Africa}, } - W. Kemmetmüller and A. Kugi, Mathematische Modellierung und Analyse eines DRT-VLF-Hochspannungsprüfgenerators, e & i Elektrotechnik und Informationstechnik, vol. 129, iss. 1, p. 18–27, 2012.

[BibTex] [Download]@Article{Kemmetmuller12, Title = {{Mathematische Modellierung und Analyse eines DRT-VLF-Hochspannungspr\"ufgenerators}}, Author = {W. Kemmetm\"uller and A. Kugi}, Journal = {e {\&} i Elektrotechnik und Informationstechnik}, Pages = {18--27}, Volume = {129}, Year = {2012}, Number = {1}, Doi = {10.1007/s00502-012-0073-5}, } - Echtzeitfähige Implementierung von optimierungsbasierten Regelungsmethoden

- Modellprädiktive Regelung mit Berücksichtigung von Systembeschränkungen

- Pfadplanung

- Pfadfolgeregelung

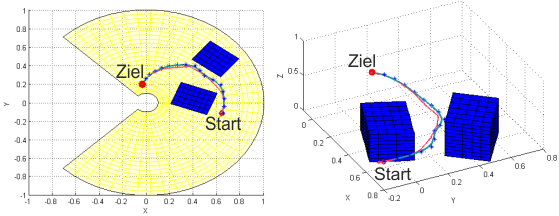

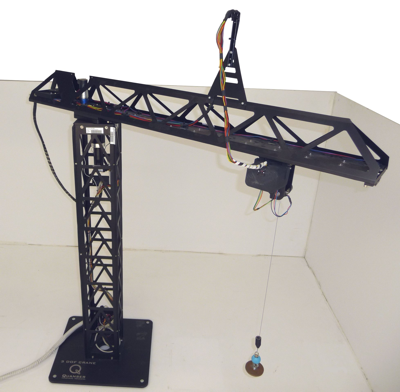

- Trajektorienfolgeregelung: Dabei wird die zeitliche Evolution entlang des geometrischen Pfades von vornherein festgelegt. Der Regler hat die Aufgabe, die Hakenposition dieser zeitlich parametrierten Trajektorie nachzuführen. Dies wurde im Rahmen des CLIC-Projektes (Closed-Loop Integration of Cognition, Communication and Control, 2009-2010) umgesetzt. Ein weiteres Ziel dieses Projektes war es, basierend auf Informationen eines verteilten Bildverarbeitungssystems in Echtzeit einen geeigneten kollisionsfreien Pfad zu ermitteln. Die Vernetzung aller Komponenten erfolgt dabei über eine echtzeitfähige Kommunikationsstruktur. Damit kann auch auf bewegte Hindernisse reagiert werden.

Verfolgung einer Trajektorie zur Vermeidung von Kollisionen mit Hindernissen, Darstellung von Ist- (rot) und Solltrajektorie (grün) des Kranhakens.

Neben dem ACIN waren am CLIC-Projekt auch das Institut für Technische Informatik (Technische Universität Wien), das Institut für Vernetzte und Eingebettete Systeme (Alpen-Adria-Universität Klagenfurt) und die TTTech Computertechnik AG beteiligt.

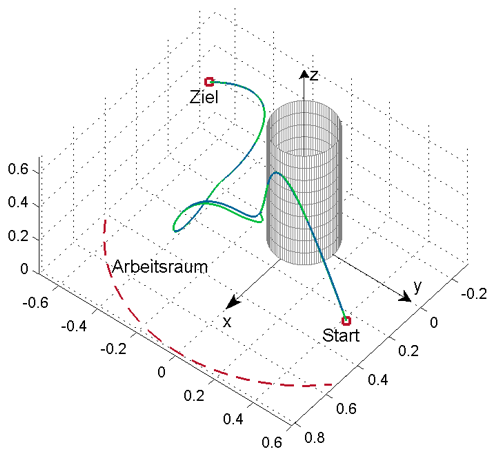

- Pfadfolgeregelung: Bei dieser wird auch die zeitliche Evolution entlang des geometrischen Pfades vom Regler bestimmt. Dadurch kann die örtliche Verfolgung des Pfades gegenüber der Zeitdauer der Pfadverfolgung priorisiert werden. Beim Auftreten von Störeinwirkungen ist es damit möglich, erst nach dem Ausregeln der aufgetretenen Abweichungen die Verfolgung des Pfades in Richtung des Zielpunktes wieder aufzunehmen.

Pfadfolgeregelung mit Störung in Form einer externen Krafteinwirkung auf den Kranhaken, Darstellung von Ist- (grün) und Sollpfad (blau) des Kranhakens.

- M. Böck and A. Kugi, Real-time Nonlinear Model Predictive Path-Following Control of a Laboratory Tower Crane, IEEE Transactions on Control Systems Technology, vol. 22, iss. 4, p. 1461–1473, 2014.

[BibTex] [Download]@Article{Boeck14, Title = {Real-time Nonlinear Model Predictive Path-Following Control of a Laboratory Tower Crane}, Author = {B{\"o}ck, Martin and Kugi, Andreas}, Journal = {IEEE Transactions on Control Systems Technology}, Pages = {1461--1473}, Volume = {22}, Year = {2014}, Number = {4}, Doi = {10.1109/TCST.2013.2280464}, } - M. Böck and A. Kugi, Manifold Stabilization and Path-Following Control for Flat Systems with Application to a Laboratory Tower Crane, in Proceedings of the 53rd IEEE Conference on Decision and Control (CDC), Los Angeles, USA, 2014, p. 4529–4535.

[BibTex] [Download]@InProceedings{Boeck14b, author = {Martin B{\"o}ck and Andreas Kugi}, title = {Manifold Stabilization and Path-Following Control for Flat Systems with Application to a Laboratory Tower Crane}, booktitle = {Proceedings of the 53rd IEEE Conference on Decision and Control (CDC)}, year = {2014}, month = {12}, pages = {4529--4535}, doi = {10.1109/CDC.2014.7040096}, address = {Los Angeles, USA}, } - M. Egretzberger, K. Graichen, and A. Kugi, Flatness-Based MPC and Global Path Planning Towards Cognition-Supported Pick-and-Place Tasks of Tower Cranes, in Advanced Dynamics and Model-Based of Control Structures and Machines, H. Irschik, M. Krommer, and A. Belyaev, Eds., Wien: Springer, 2011, p. 63–72.

[BibTex]@Incollection{Egretzberger11e, Title = {Flatness-Based MPC and Global Path Planning Towards Cognition-Supported Pick-and-Place Tasks of Tower Cranes}, Author = {M. Egretzberger and K. Graichen and A. Kugi}, Booktitle = {Advanced Dynamics and Model-Based of Control Structures and Machines}, Publisher = {Springer}, Year = {2011}, Address = {Wien}, Editor = {H. Irschik and M. Krommer and A. Belyaev}, Pages = {63--72}, Doi = {10.1007/978-3-7091-0797-3_8}, } - K. Graichen, M. Egretzberger, and A. Kugi, Suboptimal model predictive control of a laboratory crane, in 8th IFAC Symposium on Nonlinear Control Systems (NOLCOS), Bologna, Italy, 2010, p. 397–402.

[BibTex]@InProceedings{Graichen10, author = {K. Graichen and M. Egretzberger and A. Kugi}, title = {Suboptimal model predictive control of a laboratory crane}, booktitle = {8th IFAC Symposium on Nonlinear Control Systems (NOLCOS)}, year = {2010}, pages = {397--402}, doi = {10.3182/20100901-3-IT-2016.00140}, address = {Bologna, Italy}, } - K. Graichen, M. Egretzberger, and A. Kugi, Ein suboptimaler Ansatz zur schnellen modellprädiktiven Regelung nichtlinearer Systeme, at – Automatisierungstechnik, vol. 58, p. 447–456, 2010.

[BibTex]@Article{Graichen10c, Title = {Ein suboptimaler {A}nsatz zur schnellen modellpr{\"a}diktiven {R}egelung nichtlinearer {S}ysteme}, Author = {K. Graichen and M. Egretzberger and A. Kugi}, Journal = {at -- Automatisierungstechnik}, Pages = {447--456}, Volume = {58}, Year = {2010}, Doi = {10.1524/auto.2010.0860}, } - Institut für Technische Informatik (Technische Universität Wien)

- Institut für Vernetzte und Eingebettete Systeme (Alpen-Adria-Universität Klagenfurt)

- TTTech Computertechnik AG

- Zeitoptimale Prozessabläufe

- Visuelle Positionsregelung

- Flexible Produktionssysteme

- M. W. Hofmair, M. Melik-Merkumians, M. Böck, M. Merdan, G. Schitter, and A. Kugi, Patching process optimization in an agent-controlled timber mill, Journal of Intelligent Manufacturing, vol. 28, iss. 1, p. 69–84, 2017.

[BibTex] [Download]@Article{Hofmair14, Title = {Patching process optimization in an agent-controlled timber mill}, Author = {Hofmair, Matthias Wolfgang and Melik-Merkumians, Martin and B\"ock, M. and Merdan, M. and Schitter, G. and Kugi, A.}, Journal = {Journal of Intelligent Manufacturing}, Pages = {69--84}, Volume = {28}, Year = {2017}, Number = {1}, Doi = {10.1007/s10845-014-0962-z}, ISSN = {1572-8145}, } - M. W. Hofmair, Process Optimization and Control of a Patching Plant for Shuttering Panels, A. Kugi and K. Schlacher, Eds., Aachen: Shaker Verlag, 2016, vol. 32.

[BibTex]@Book{Hofmair16, Title = {Process Optimization and Control of a Patching Plant for Shuttering Panels}, Author = {Hofmair, M. W.}, Editor = {A. Kugi and K. Schlacher}, Publisher = {Shaker Verlag}, Year = {2016}, Address = {Aachen}, Series = {Modellierung und Regelung komplexer dynamischer Systeme}, Volume = {32}, ISBN = {978-3-8440-4745-5}, Organization = {Institute f{\"u}r Automatisierungs- und Regelungstechnik (TU Wien) und Regelungstechnik und Prozessautomatisierung (JKU Linz)}, } - M. W. Hofmair, M. Böck, and A. Kugi, Time-Optimal Trajectory Generation, Path Planning and Control for a Wood Patching Robot, in Proceedings of the 2015 IEEE Conference on Control Applications (CCA), Sydney, Australia, 2015, p. 459–465.

[BibTex]@InProceedings{Hofmair15, author = {Hofmair, Matthias Wolfgang and B\"ock, Martin and Kugi, Andreas}, title = {Time-Optimal Trajectory Generation, Path Planning and Control for a Wood Patching Robot}, booktitle = {Proceedings of the 2015 IEEE Conference on Control Applications (CCA)}, year = {2015}, publisher = {IEEE}, month = {9}, pages = {459--465}, doi = {10.1109/CCA.2015.7320672}, address = {Sydney, Australia}, } - Lip Opazne Plosce Bohinj Doo (Slovenien)

- Lulea Tekniska Universitet (Schweden)

- MiCROTEC (Italien)

- Springer (Österreich)

- Technische Universität München (Deutschland)

- TTTech (Österreich)

- Projektakronym: Hol-I-Wood PR

- Projekttitel: Holonic Integration of Cognition, Communication and Control for a Wood Patching Robot

- Projektnummer: 284573

- Optimalsteuerungen für nichtlineare Mehrgrößensysteme

- Energieeffizienz

- Experimentelle Verifikation

- Produktionsanlagen

- Handlingsysteme

- A. Pfeffer, T. Glück, and A. Kugi, Soft Landing and Disturbance Rejection for Pneumatic Drives with Partial Position Information, in Proceedings of the 7th IFAC Symposium on Mechatronic Systems & 15th Mechatronics Forum International Conference, Loughborough, UK, 2016, p. 559–566.

[BibTex] [Download]@InProceedings{Pfeffer16a, author = {Pfeffer, A. and Gl\"uck, T. and Kugi, A.}, title = {Soft Landing and Disturbance Rejection for Pneumatic Drives with Partial Position Information}, booktitle = {Proceedings of the 7th IFAC Symposium on Mechatronic Systems \& 15th Mechatronics Forum International Conference}, year = {2016}, volume = {49}, number = {21}, month = {9}, pages = {559--566}, doi = {10.1016/j.ifacol.2016.10.661}, address = {Loughborough, UK}, issn = {2405-8963}, }

23.08.2017 Regelung von Pumpspeicherkraftwerken

Projektschwerpunkte

Beschreibung

Durch den vermehrten Ausbau von erneuerbaren Energieerzeugungssystemen (Windkraft, Sonnenkraft) ist der Anteil an Kraftwerken mit stark fluktuierender Leistung in den europäischen Energieverteilungsnetzwerken wesentlich angestiegen. Um die Stabilität der Netzwerke zu garantieren sind daher entsprechende Speicher notwendig. Die am weitesten verbreitete Möglichkeit zur Speicherung von elektrischer Energie sind Pumpspeicherkraftwerke, die im Wesentlichen aus zwei Wasserbecken auf unterschiedlicher Meereshöhe bestehen, welche über Rohrleitungen und Turbinen miteinander verbunden sind, siehe Abb. 1. Wenn nun überschüssige Leistung im Netz vorhanden ist, so wird Wasser vom unteren ins obere Becken gepumpt. Umgekehrt wird Leistung ins Netz abgegeben indem Wasser vom oberen Becken über die Turbine ins untere Becken gefördert wird.

Typischer Aufbau eines Pumpspeicherkraftwerkes

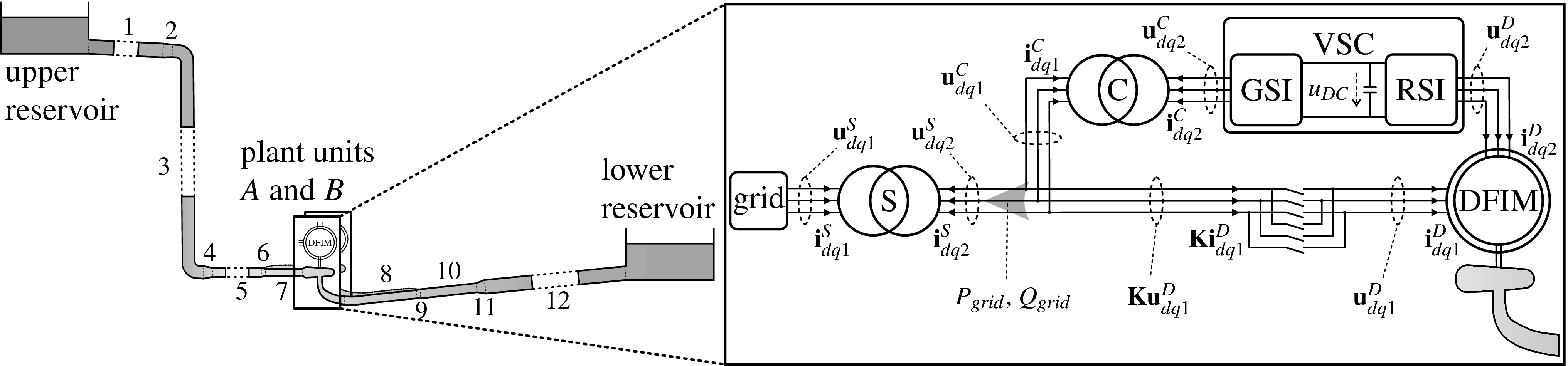

In diesem Forschungsprojekt werden in Kooperation mit der Firma Andritz Hydro Regelungsstrategien für den optimalen dynamischen Betrieb von Pumpspeicherkraftwerken entwickelt. Es werden Anlagen mit konstanter Drehzahl (Synchronmaschine) und drehzahlvariable Anlagen (doppelt-gespeiste Asynchronmaschine oder Synchronmaschine mit Vollumrichter)betrachtet. Ein typischer Aufbau eines Pumpspeicherkraftwerks mit doppelt-gespeisten Asynchronmaschinen (DFIM) ist in Abb. 2 dargestellt.

Komponenten eines drehzahlvariablen Pumpspeicherkraftwerks

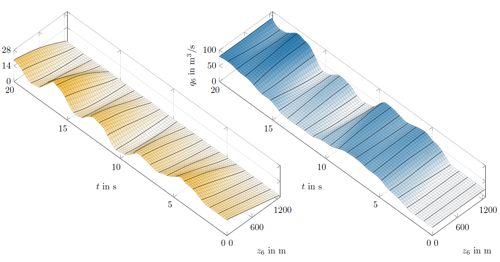

Eine wesentliche Schwierigkeit bei der dynamischen Regelung von Pumpspeicherkraftwerken sind die häufig sehr langen Rohrleitungen (im Bereich von bis zu einigen Kilometern), die die Turbinen mit den Becken verbinden. Bei schnellen Verstellungen der Turbine werden dabei Druckwellen angeregt, die sich in den Leitungen ausbreiten (Druckstoß) und zu einer hohen Belastung bis zum Defekt der Rohrleitungen führen können. Die Abb. 3 zeigt einen typischen Verlauf des Drucks und des Volumenstroms entlang einer Druckrohrleitung bei einem schnellen Schließen der Turbine.

Örtlicher und zeitlicher Verlauf des Drucks und Volumenstroms einer Rohrleitung

Um diese Effekte zu beschreiben werden in diesem Projekt Approximationen der infinit-dimensionalen Gleichungen hergeleitet, wobei ein besonderer Schwerpunkt auf eine möglichst hohe numerische Effizienz gelegt wird. Dies ist vor allem für den Einsatz der Modelle in modellbasierten Regelungsstrategien von besonderer Bedeutung. Auf Basis dieser Modelle werden optimale Regelungsstrategien, insbesondere modellprädiktive Ansätze, untersucht. Auf Basis dieser Modelle und den Modellen des elektrischen Systems wird ein skalierbarer physikalisch-basierter digitaler Zwilling (einschließlich Sensoren und Aktoren) entwickelt. Der physikalisch-basierte digitale Zwilling ermöglicht eine einfache Anpassung an verschiedene Topologien von Pumpspeicherkraftwerken (Anzahl der Rohrleitungen, Turbinen- und Generatortypen, verschiedene Elemente im elektrischen System) unter Verwendung von Konstruktionsparametern der Anlagen. Der digitale Zwilling dient auch zur Untersuchung optimaler Regelstrategien (modellprädiktive Regelung). Das Ziel ist dabei eine wesentliche Erhöhung der Regeldynamik (und damit des Potenzials für eine Stabilisierung von Schwankungen im Verteilnetz) bei Beibehaltung bzw. Erhöhung des Wirkungsgrads. Die optimale Steuerung hochdynamischer Transienter (z. B. Lastabwurf) wird ebenfalls untersucht.

Ein weiterer Schwerpunkt des Projekts liegt im optimalen Anlagebetrieb. Ein Aspekt ist die optimale wirtschaftliche Kraftwerksauslastung mittels Day-Ahead-Optimierungen und der Regelung kurzfristiger Überlastungen, um im Intraday-Handel zur Verfügung stehende Reserven zu vermarkten. Ein weiterer Aspekt ist der Kraftwerksbetrieb bei minimalem Verschleiß, um die Lebensdauer des Kraftwerks zu verlängern.

Ausgewählte Publikationen

Projektpartner und Förderung

22.08.2017 Elektrorheologische Flüssigkeiten

Projektschwerpunkte

Beschreibung

In der klassischen Hydraulik werden Ventile verwendet um den Volumenstrom in einem hydraulischen System zu steuern. Das Grundprinzip beruht auf der Veränderung des Strömungsquerschnitts durch die Bewegung eines mechanischen Bauteils, z.B. des Ventilschiebers. Im Vergleich dazu erlauben elektrorheologische Flüssigkeiten eine direkte Änderung der rheologischen Eigenschaften der Flüssigkeit (im Wesentlichen der scheinbaren Viskosität) durch Anlegen eines hinreichend großen elektrischen Feldes. Dies ermöglicht die Beeinflussung des Volumenstroms in einem hydraulischen System ohne mechanische Bewegungen. Da dieser elektrorheologische (ER) Effekt sehr schnell ist (im Bereich weniger Millisekunden) erlaubt die Verwendung von ER-Flüssigkeiten (ERF) den Aufbau von sehr schnellen hydraulischen Aktoren. Weiterhin bietet die direkte Beeinflussung der Viskosität von ERF die Möglichkeit des Aufbaus von Ventilen ohne bewegliche Bauteile und somit sehr einfache Konstruktionen.

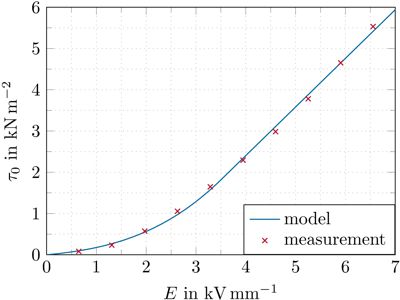

Im Rahmen der Forschungsarbeiten am Gebiet der ERF wurden mehrere mögliche Anwendungen im Bereich der Ventiltechnik, in elektrorheologischen Linearaktoren bzw. in Fahrzeugdämpfern bis hin zu Schockabsorbern für den maritimen Bereich untersucht. Die Basis lag dabei auf einer kontinuumsmechanischen Beschreibung der Eigenschaften der ERF (Spannung) als Funktion des angelegten elektrischen Feldes und der Scherrate. Ein typischer Verlauf der Schubspannung als Funktion der elektrischen Feldstärke einer ERF ist in Abb. 1 dargestellt.

Schubspannung einer ERF als Funktion der elektrischen Feldstärke

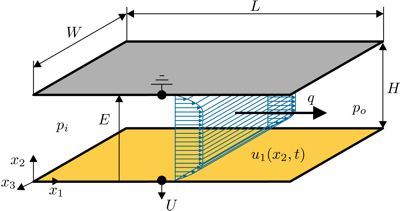

Die zentrale elektrorheologische Komponente ist ein ER-Ventil, welches im Wesentlichen aus zwei (parallelen) Elektroden besteht zwischen denen die ERF fließt, siehe Abb. 2. Durch Anlegen einer Spannung an die Elektroden kann der Fließwiderstand erhöht werden. Bei hinreichend hoher elektrischer Spannung kann das Ventil sogar vollständig gesperrt werden.

Grundaufbau eines ER-Ventils

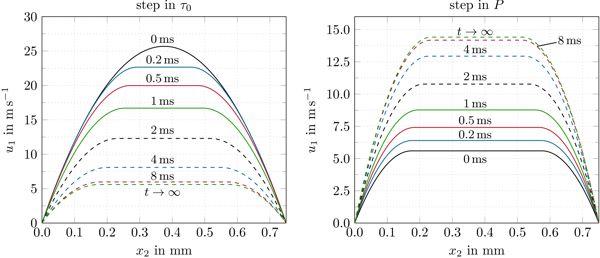

Diese Beeinflussung der Strömung erfolgt, wie bereits erwähnt, sehr schnell. In Abb. 3 ist der typische Verlauf der Fließgeschwindigkeit \(u_1\) der ERF in einem Ventil nach Abb. 2 für eine sprungförmige Änderung der Spannung bzw. des Drucks am Ventil dargestellt.

Änderung der Strömungsgeschwindigkeit in einem ER-Ventil für sprungförmige Änderung der Spannung bzw. des Drucks

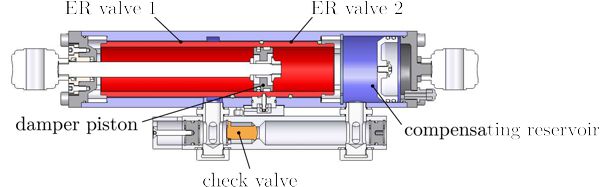

Ein mögliches Anwendungsgebiet von ERF und ER-Ventilen sind Fahrzeugdämpfer. In semi-aktiven Radaufhängungssystemen werden verstellbare Dämpfer verwendet um einen bestmöglichen Kompromiss zwischen Fahrkomfort und Fahrsicherheit zu erreichen. Dies wird durch eine Anpassung der Dämpfung an die Fahrsituation bzw. die Fahrbahnbeschaffenheit erreicht. Die Abb. 4 zeigt einen in Kooperation mit der Firma Fludicon entwickelten semi-aktiven Fahrzeugdämpfer, der für den Einsatz in Nutzfahrzeugen gedacht ist. Im Rahmen einer Forschungskooperation mit der Firma Fludicon erfolgte die Entwicklung von mathematischen Modellen sowie von Regelungsstrategien für Fahrzeuge, die mit diesen ER-Dämpfern ausgestattet sind. Anhand von Fahrversuchen mit einem Testfahrzeug konnte eine wesentliche Verbesserung des Verhaltens des Fahrzeuges im Vgl. zu einem passiven Fahrwerk gezeigt werden.

Schnittbild eines ER-Dämpfers

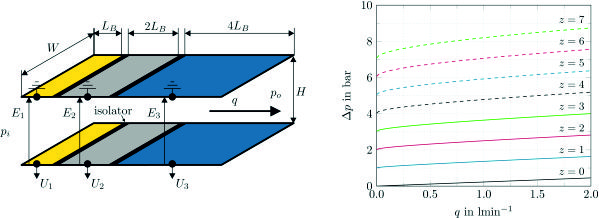

Die direkte Änderung der Eigenschaften der ERF durch ein elektrisches Feld erlaubt die gezielte Beeinflussung der Strömung durch geeignete Gestaltung der Elektrodengeometrie. Z.B. wurden im Rahmen eines weiteren Forschungsprojektes in Kooperation mit der Firma Fludicon digitale ER-Ventile entwickelt. Die Grundidee besteht dabei darin, den Strömungswiderstand durch geeignetes geschaltetes Ansteuern von mehreren seriell geschalteten ER-Ventilen stufenförmig zu verstellen. Dies erlaubt den Einsatz von günstigeren Hochspannungsquellen mit konstanter Spannung. Durch die Anpassung der Elektrodengeometrie, z.B. entsprechend einer binären Kodierung, können sehr geringe Stufenhöhen bereits mit einer geringen Anzahl von Einzelventilen erreicht werden, siehe Abb. 5. Mögliche Einsatzgebiete sind wiederum semi-aktive Dämpfungssysteme im Fahrzeugbereich.

Serielles digitales ER-Ventil mit zugehöriger Charakteristik

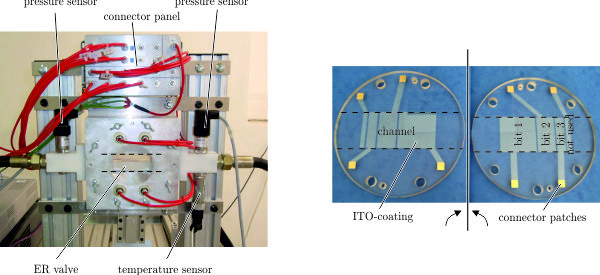

Zur Überprüfung der Eigenschaften der ERF und der entwickelten ER-Ventile wurde ein Prüfstand aufgebaut. Durch den Einsatz von transparenten Elektroden erlaubt dieser Prüfstand eine direkte Beobachtung der Strömung im Ventil und damit Rückschlüsse auf die Strömungsformen, siehe Abb. 6.

ER-Prüfstand und Elektroden eines digitalen ER-Ventils

In den nachfolgenden Videos sind drei Messungen dieses Prüfstands dargestellt. Das erste Video zeigt das in Abb. 6 dargestellte digitale ER-Ventil und die Änderung der Strömung bei abwechselnder Aktivierung der einzelnen Teilventile. Die Videos 2 und 3 zeigen eine Möglichkeit zur Führung einer Strömung von ERF entsprechend eines gewünschten Pfades (sinusförmig). Insbesondere wird gezeigt, wie Gebiete abseits des Pfades durch Anlegen einer Spannung gesperrt werden können ohne einen mechanischen Eingriff durchzuführen. Die Ergebnisse dieser Experimente können die Basis z.B. für Ventile in Matrixbauweise darstellen, die eine frei konfigurierbare Verbindung von mehreren Zu- und Abflüssen ohne mechanische Komponenten erlauben.

Ausgewählte Publikationen

Projektpartner

16.08.2017 Aktive Kamerastabilisierungsplattform

Projektschwerpunkte

Beschreibung

In vielen Filmszenen oder Video-Clips wird die Kamera dynamisch bewegt um die Perspektive zu wechseln oder um spannendere Filme zu erzeugen. Typischerweise kommen Kamerakräne, Steady-Cam Systeme, Kabelkameras oder Helikopterkameras zum Einsatz wenn solche Szenen produziert werden. Um unerwünschte Änderungen der Ausrichtung der Kamera zufolge der Bewegung des beweglichen Benutzers zu unterdrücken muss die Kamera stabilisiert werden. Dazu werden meist inertial stabilisierte Plattformen (ISP) mit kardanischer Aufhängung verwendet.

In diesem Projekt wurde eine neuartige aktive Kamerastabilisierungsplattform betrachtet, die vom Projektpartner qinematiq entwickelt wurde. Sie besitzt eine kardanische Aufhängung mit drei Freiheitsgraden, welche über in den Gelenken eingebaute Motoren aktuiert werden. Zur Messung der Orientierung der Kamera bzw. des Handgriffes der Plattform werden Inertialsensoren (IMUs) verwendet, siehe Abb. 1.

Experimenteller Aufbau der Kamerastabilisierungsplattform

Die wesentliche Regelungsaufgabe besteht in der Regelung der Orientierung der Kamera entsprechend dem Wunsch des Kameramanns. Für diese Aufgabe wurde eine flachheitsbasierte Regelungsstrategie entwickelt, welche auf Schätzung der Orientierung der Kamera und des Handgriffes der Plattform beruht. Diese Schätzwerte wurden mit Hilfe eines multiplikativen Extended Kalmanfilters ermittelt, welches die Messwerte aller Sensoren der Plattform fusioniert. Ein wesentlicher Schritt zum Erreichen der gewünschten Genauigkeit der Plattform war der Entwurf bzw. die Auswahl und Platzierung der Aktoren und Sensoren. Die praktische Verwendbarkeit der gesamten Regelungs- und Schätzstrategie wurde anhand von Experimenten an einem Prototypen der Plattform nachgewiesen.

Ausgewählte Publikationen

Projektpartner und Förderung

16.08.2017 Mobiler DRT-VLF Prüfgenerator

Projektschwerpunkte

Beschreibung

In den letzten Jahren ist ein forcierter Ausbau der Energieerzeugung mittels regenerativer Systeme, wie z.B. Windkraftanlagen (On- und Off-Shore), Photovoltaik sowie Biomasse, zu verzeichnen. Die Anbindung dieser dezentralen Anlagen an das bestehende Stromverteilungsnetz erfolgt in der Regel mit Hilfe von Hoch- und Höchstspannungskabeln (HV, UHV) mit Spannungen bis zu 500 kV, welche in der Erde oder im Meer verlegt werden. Zum Testen der geforderten Funktionalität sowie zur Erkennung von Defekten bereits verlegter Kabel werden geeignete Prüfmethoden und -geräte benötigt.

Da die verbauten Hoch- bzw. Höchstspannungskabel sehr große Kabelkapazitäten besitzen, würde ein Test mit Netzfrequenz zu sehr hohen Blindleistungen führen, was sich direkt in der Baugröße und dem Gewicht niederschlägt. Für eine Reduktion der Blindleistung und damit der Größe des Prüfgenerators erfolgt daher vermehrt die Prüfung mit Testspannungen sehr niedriger Frequenz (VLF, ca. 0,01 Hz – 10 Hz).

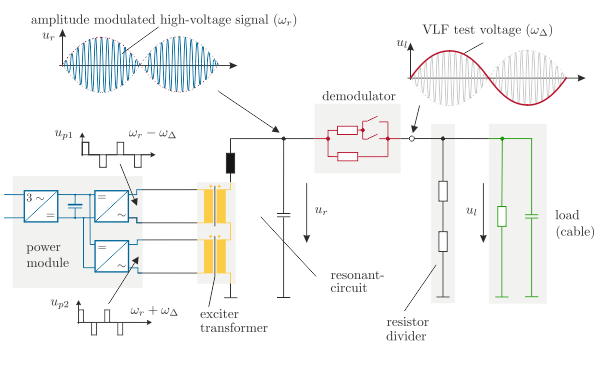

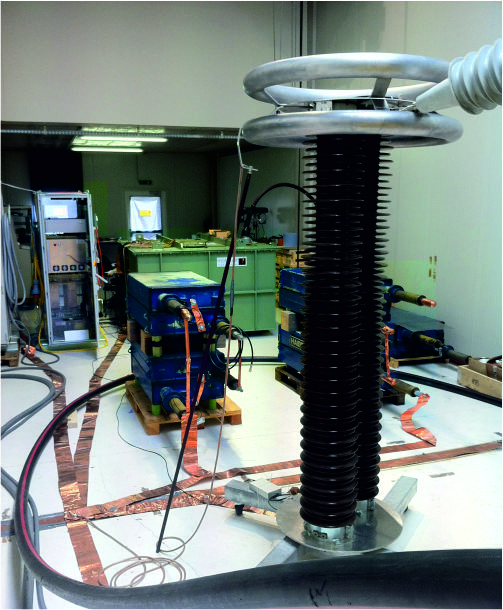

Prototyp des VLF Prüfgenerators der Firma mohaupt high voltage

Im Zuge dieses Projekts wurde der in Abb. 1 dargestellte Prototyp eines von der Firma mohaupt high voltage entwickelten VLF Prüfgenerators betrachtet. Abbildung 2 zeigt den prinzipiellen Aufbau des Hochspannungsprüfgenerators. Dieser besteht aus einem Leistungsmodul mit anschließendem Resonanzkreis, welche zur Erzeugung einer amplitudenmodulierten Hochspannung verwendet werden. Mit Hilfe der Demodulatoreinheit wird schließlich die gewünschte niederfrequente Prüfspannung im Frequenzbereich von 0,01 bis 10 Hz am Hochspannungskabel erzeugt.

Funktionsprinzip des DRT VLF Prüfgenerators

Für dieses System wurde im Rahmen des Projektes ein detailliertes mathematisches Modell unter Berücksichtigung der nichtlinearen Eigenschaften insbesondere des Demodulators erstellt. Basierend auf einer Analyse des Modells wurde ein reduziertes Hüllkurvenmodell ermittelt, welches die Basis für den weiteren Regler- und Beobachterentwurf darstellt. Die entworfene Regelungsstrategie basiert auf einer Minimierung der Verlustleistung des Systems in Kombination mit einer Optimierung der Güte der Ausgangsspannung (Minimierung des THD-Wertes). Zur Schätzung der unbekannten Last (das Kabel) wurde die Regelungsstrategie um eine Schätzstrategie für die Kabelkapazität erweitert. Schließlich wurde gezeigt, dass eine optimierte Wahl der Konstruktionsparameter des Systems im Sinne eines mechatronischen Systementwurfs zu einem optimierten Gesamtsystem führt. Anhand von Messungen am Prototyp konnte ein hohe Regelgüte und Robustheit der entworfenen Regelungs- und Schätzstrategie nachgewiesen werden.

Prüfaufbau zum Test der Regelungs- und Schätzstrategien

Ausgewählte Veröffentlichungen

Projektpartner und Förderung

05.07.2017 Optimierungsbasierte Regelungsmethoden an einem Turmdrehkran im Labormaßstab

Projektschwerpunkte

Beschreibung

Turmdrehkräne sind sehr weit verbreitet und stellen ein interessantes Anwendungsgebiet für die Regelungstechnik dar. Eine wichtige Aufgabenstellung ist das Positionieren des Hakens unter gleichzeitiger Minimierung von Pendelbewegungen des Seils an der Sollposition. Eine weitere mögliche Zielsetzung ist die Unterdrückung von Störungen wie zum Beispiel Windkräfte und unterschiedlich große Lastmassen.

Für die Erfüllung der obigen und weiterer Aufgabenstellungen werden geeignete Regelungskonzepte entwickelt und an einem Turmdrehkran im Labormaßstab getestet. Der Schwerpunkt liegt dabei auf optimierungsbasierten Ansätzen, im Speziellen aus dem Bereich der modellprädiktiven Regelung (MPC). Diese ermöglicht neben der Erfüllung der primären Zielsetzung auch die Berücksichtigung von Systembeschränkungen und das Erreichen eines optimalen Verhaltens des geschlossenen Regelkreises im Sinne des zugrundeliegenden Kostenfunktionals. Darunter fällt beispielsweise die Minimierung des Energieverbrauches der Antriebsmotoren.

Turmdrehkran im Labormaßstab.

Zur Vermeidung von Kollisionen mit Hindernissen ist es erforderlich, dass der Haken bzw. die Lastmasse einem vorgegebenen kollisionsfreien Pfad möglichst genau folgt. Diese Aufgabenstellung kann von zwei Blickwinkeln betrachtet werden.

Ausgewählte Veröffentlichungen

Projektpartner und Förderung

Das CLIC-Projekt wurde gefördert durch das FIT-IT Programm der Österreichischen Forschungsförderungsgesellschaft (FFG) (Projektnr. 819482). Neben dem ACIN waren beteiligt:

04.07.2017 Hol-I-Wood PR

Projektschwerpunkte

Beschreibung

Die Korrektur von natürlichen Holzdefekten, wie z.B. Harztaschen oder Astlöchern, unterbricht die automatisierten Produktionsabläufe in der Holzindustrie. Dabei ist die menschliche Arbeitskraft insbesondere für die Detektion und Klassifikation von Holzdefekten sowie für deren Reparatur erforderlich.

Diese für den Menschen monotone und mühselige Arbeit wird im Rahmen des Projekts „Holonic Integration of Cognition, Communication and Control for a Wood Patching Robot“, kurz „Hol-I-Wood PR“, automatisiert. Diese innovative so genannte „Wood Patching“-Anlage wird in die Schalungsplattenproduktion unserer Partner integriert.

Loser Ast.

Ein Multisensorsystem scannt die Schalungsplatten und ermittelt die Defektdaten, wie beispielsweise die Position und den Umriss des losen Astes aus Abb. 1. Ein so genannter Patch-Roboter korrigiert die Defekte durch Ausbohren und Einschlagen eines oder mehrerer Stopfen (engl. patches), siehe Abb. 2. Dabei bedient der Holzscanner mehrere Produktionslinien, welche über Kreuzungen miteinander verbunden sind. Bei diesem Prozess treten Optimierungsprobleme in vielfältiger Form auf, die in Echtzeit gelöst werden müssen.

Anfangs werden für jeden Defekt die minimale Anzahl an Stopfen und deren Anordnung berechnet. Dabei unterliegt die Anordnung der Stopfen starken Einschränkungen, da sichergestellt werden muss, dass sie fest mit der Platte verbunden sind.

Dann wird der zeitoptimale Roboterpfad zwischen den einzelnen Stopfen geplant. Dieses anspruchsvolle kombinatorische Optimierungsproblem, ähnlich des so genannten „Travelling Salesman Problems“, ist darüberhinaus zeitvariant, da die Schalungsplatten flexibel zu den einzelnen Produktionslinien zugeteilt werden und somit die anzufahrenden Fehlstellen dem jeweiligen Patch-Roboter zeitlich versetzt bekanntgegeben werden.

Der Patch-Roboter ruft nach erfolgter Plattenzuteilung die notwendigen Daten aus einer Datenbank ab, bewegt die Platte mithilfe zeitoptimaler Trajektorienplanung und visueller Positionsregelung entlang des gewünschten Pfades und platziert die Stopfen.

Dabei werden die Positionsdaten der Platte vom Kamera-Netzwerk mit Positionsdaten „konventioneller“ Sensoren, die jeweils mit unterschiedlichen Abtastzeiten und Genauigkeiten zur Verfügung stehen, kombiniert.

Korrigierter Defekt.

Aufgrund der Toleranzen des natürlichen Werkstoffes Holz und der rauen Produktionsumgebung in Sägewerken muss die Automation robust, fehlertolerant und flexibel ausgelegt werden. Dies erfolgt durch den Einsatz moderner Regelungs- und Beobachterkonzepte.

Darüberhinaus erreicht die Forschungsgruppe für Automatisierungs- und Steuerungssysteme des ACIN durch automatisierte flexible Zuteilung, Umleitung und gegebenenfalls auch durch Pufferspeicherung der Schalungsplatten zwischen den einzelnen Produktionslinien eine gleichmäßige, höchstmögliche Anlagenauslastung. Bei Störung einer oder mehrerer Patch-Roboter werden die Schalungsplatten sofort neu zugeteilt, ohne dass es zu unnötig hohen Produktionsausfällen kommt.

Anwendungsbereiche

Die Reparatur von Fehlstellen im Holz steigert dessen Wert unabhängig von der endgültigen Verwendung. Bei Schalungsplatten wird deren Funktion sichergestellt, bei Möbeln, Fensterrahmen o.Ä. wird das Erscheinungsbild verbessert.

Generell treten ähnliche Problemstellungen, wie z.B. optimale Pfadplanung, Positionierung von Werkstücken, welche nur durch Reibschluss (nicht durch Formschluss) bewegt werden oder maximale Anlagenauslastung, in weiten Bereichen der Prozesskettenoptimierung auf.

Ausgewählte Veröffentlichungen

Projektpartner und Förderung

Am Projekt „Hol-I-Wood PR“ arbeiteten zusammen mit dem ACIN drei weitere öffentliche Forschungseinrichtungen und vier Industriepartner aus fünf Ländern der EU:

Das Projekt wurde im 7. Rahmenprogramm der Europäischen Kommission gefördert.

29.06.2017 Modellierung, Beobachterentwurf und Regelung von kontinuierlichen Bandbehandlungsanlagen

29.06.2017 Optimalsteuerung pneumatischer Linearaktoren

Projektschwerpunkte

Beschreibung

Die Pneumatik erfeut sich in den unterschiedlichsten Industriezweigen großer Beliebtheit. Vor allem der Einsatz von pneumatischen Linearaktoren ist in der heutigen Automatisierungstechnik nicht mehr wegzudenken.

Die zukünftigen Anforderungen an pneumatische Linearaktoren zielen auf schnelle hochgenaue Punkt-zu-Punkt Positionierungen mit möglichst geringem Sensoraufwand ab. Der Verzicht auf eine kontinuierliche Positionssensorik und der Einsatz einer kostengünstigen, diskreten Wegmessung stellt für den Entwurf einer Regelung für die Punkt-zu-Punkt Positionierung eine besondere Herausforderung dar. Die fehlende kontinuierliche Positionsinformation muss durch eine intelligente Regelung des Antriebs kompensiert werden.

Horizontaler Prüfstand mit pneumatischen Linearaktor

Ventilblock mit Schnellschaltventilen.

Für die Ansteuerung der Linearaktoren werden in diesem Projekt kostengünstige Schnellschaltventile verwendet. Die optimale Ansteuerung dieser zur Durchführung einer Punkt-zu-Punkt Bewegung des pneumatischen Kolbens ist Ziel dieses Projektes. Dabei soll eine zeitoptimale und eine energieminimale Positionierung des pneumatischen Kolbens erreicht werden, welche robust gegenüber Druckversogrungsschwankungen und Laständerungen ist.