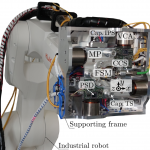

Precision robotic inline metrology for freeform surfaces

High precision in-line measurements on free form surfaces are considered a key factor for the industrial production of the future. Robot-based measurement systems provide the required flexibility but are typically lacking the required precision. The scope of this project is the development of a measurement platform designed as end effector for industrial robots, which carries a measurement or inspection tool and compensates for environmental disturbances, enabling precision 3D measurements on both arbitrarily oriented and moving samples. Weiterlesen →

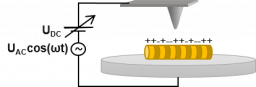

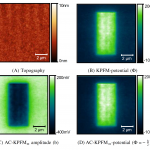

High-precision electrical AFM modes for biological applications2016 - 2018

Electrical modes of Atomic Force Microscopy (AFM) allow the high-resolution mapping of surface charges on a sample with nanometer precision. A particular measurement challenge is to perform such modes on biological samples (tissue extracts, biomolecules, biomembranes, etc). To this end, the project aims to investigate different preparation and measurement approaches and a specific goal is to determine alterations of surface charge of biological fibers caused by the reaction with sugar, which has important implications in medicine and cell biology. Weiterlesen →

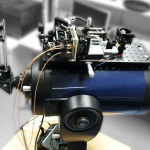

High resolution long range Lidar for autonomous driving (LiDcAR)2017 - 2020

Lidar is an acronym for light detection and ranging, in analogy to radar. Lidar has received much attention in the automotive industry as a key component for high level automated driving systems. Compared to other sensing techniques such as stereo cameras and radar, lidar can provide high resolution and highly accurate 3D measurements of the surroundings and robust detection in various weather conditions. Weiterlesen →

SatComScope2016 - 2019

This project aims to integrate adaptive optics (AO) technology into small-sized telescope systems of the industrial partner, ASA Astrosysteme, in order to enable free space optical (FSO) communication between satellites and optical ground stations. Compared to radio-frequency communication, this yields a potential increase of the data rate of more than 1 order of magnitude, while simultaneously significantly reducing the emitting power and weight on the satellite. Weiterlesen →

TracSat

The precise tracking of high velocity satellites with ground based optical telescopes is a prerequisite for a number of future applications such as optical satellite communication, observation of space debris or satellite laser ranging. To achieve this goal, good mechatronic design as well as high performance control are necessary. Together with our industrial partner, ASA Astrosysteme GmbH, this project aims on increasing the achievable precision and tracking velocity of existing ASA ground stations. Weiterlesen →

IQ AFM

Imaging, handling and manipulation of material with high resolution are important techniques for various applications of research. Atomic force microscopes (AFM) are one of the most important tools for imaging applications with spatial resolution beyond the diffraction limit of light. The project aims is to build a basic AFM-system in cooperation with Anton Paar GmbH. Weiterlesen →

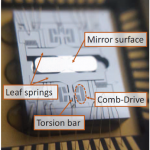

Scanning optical point- and line-sensor (SOS)

To overcome the limitation for better productivity and reliability of production in this project, a rotating or steering mirror scans the sensor’s optical point or line over a product surface, targeting triangulation, confocal, and color sensors. Weiterlesen →

Characterization of highly divergent optics (DOC)

Opto-mechatronic devices such as triangulation sensors or chromatic confocal sensors project focused light beams onto the surface of the measuring object. Assessing the properties of the focused beam is essential as they are directly related to the achievable measurement resolution and precision of the opto-mechatronic device. Weiterlesen →

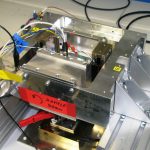

Atomic Force Microscopy capable of vibration isolation (Vibrostop AFM)

An atomic force microscope (AFM) can image and inspect a sample surface with high resolution by scanning a probe with a sharp tip over the sample. During scanning, the vertical position of the probe with respect to the sample typically needs to be regulated with nanometer resolution. For the required high resolution, AFMs are sensitive to vibrations transmitted from the floor dependent on their design. Weiterlesen →

Automated in-line metrology for nanopositioning systems (aim4np)

Robot based in-process metrology is a key enabling technology for upcoming production systems and is considered as one of the most important preconditions for future production. Measuring properties at the nanometer scale such as topography, morphology and roughness within a production line becomes increasingly important for quality control and process monitoring tasks to make high tech production more efficient. Weiterlesen →