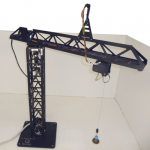

Optimization-based control methods applied to a laboratory-scale tower crane

Tower cranes are widely-used and constitute an interesting field of application for modern control theory. An important task is to control the position of the hook by suppressing the oscillating motion of the cable at the same time. Another possible goal is the rejection of disturbances such as different load masses or external forces induced by wind. Different control concepts are developed to cope with these and further goals. The resulting controllers are tested on a laboratory tower crane. The focus lies on optimization-based control methods, in particular model predictive control (MPC). Read more →

Hol-I-Wood PR

The correction of natural wood defects, such as resin galls or loose dead knots, interrupts the automatized production flow in timber industry. The human workforce is key for detection and classification of wood defects as well as for their correction. The project Hol-I-Wood PR aims at automatizing this monotone and laborious work. The resulting innovative "wood patching"-plant is going to be integrated into the shutter board production line of our partner company. Read more →

Modeling, observer design, and control of continuous strip processing lines

In continuous strip processing line, steel strips are thermally and mechanically processed as well as surface coated (e.g. galvanized). In this project, observer and control concepts for continuous galvanizing lines are developed. Additionally, controllers for laboratory facilities to develop new process technologies (e.g. laboratory furnaces) are designed. Read more →

Modeling, observer and control design of a tandem hot strip rolling mill

Rough-rolled steel plates are rolled in a tandem hot rolling mill to strip with a final thickness. This thickness should accurately and uniformly correspond with the desired value. To satisfy this requirements and to ensure a stable strip travel, model-based control concepts are developed in this project. Read more →

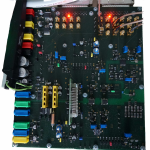

Nonlinear control and protection concepts for Smart Power ICs

Smart Power ICs are Power Switches with integrated control and protection functions for the switching of middle and high current loads in industrial and automotive applications. Due to customer specifications and electromagnetic compatibility requirements it is often desired to limit the current and voltage slew rate at the output terminal of Smart power ICs by minimizing the switching losses at the same time. Read more →

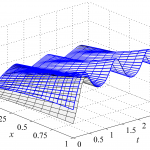

Backstepping-based observer design for parabolic PDEs with varying parameters

Model-based control and advanced process monitoring usually require full state information. This is in particular evident if control strategies are utilized by means of state feedback or if algorithms based on full state knowledge are applied to improve the insight into the system behavior, e.g., for diagnostic or error detection purposes. In general, the complete state information cannot be directly measured. This is especially true for distributed-parameter systems, i.e., systems governed by partial differential equations (PDEs).Therefore, an observer is required to estimate the state variables from the knowledge of measured input and output variables as well as the mathematical model of the system. Read more →

Flatness control in heavy plate rolling

In heavy plate rolling, the heated plates are plastically deformed between two work rolls. Here, asymmetries in the roll gap may cause up- or downward bending of the ends of the plates. This so-called ski effect affects the flatness of the plates and may entail problems in subsequent processing steps. A model-based control concept and an improved speed controller for the roll drives can avoid such ski-ends and thus increase the quality of the plates. Read more →

Modeling and control of hot levelers

Levelers are used in the production of steel plates in rollings mills to improve the flatness of the products. After rolling and cooling, a leveling machine reduces remaining flatness errors and residual stresses in the plates. This happens by alternate plastic bending of the plate material between the work rolls of the leveler. Read more →

Modeling, observer design, control, and optimization of strip annealing furnaces

In the steel industry, continuous strip annealing furnaces are used for the heat treatment of strip products. To meet the high demands on the quality of the final product, the strip has to be heated to a predefined target temperature while it moves through the furnace. This is a challenging control task because an annealing furnace is a complex, nonlinear, thermodynamical multi-input-multi-output system and many process variables cannot be measured. Read more →

Modeling and control of a four-high heavy plate rolling mill

In heavy plate rolling, the heated plate is plastically deformed between two work rolls. Various measures avoid or minimize the deflection of the work rolls and thus the lateral non-uniformity of the product thickness profile. A mathematical deflection model yields the plate exit thickness, which cannot be directly measured. A model-based feedforward strategy compensates the disturbances observed in the previous rolling pass. Read more →