Modellierung, Beobachterentwurf, Regelung und Optimierung von Bandglühöfen

Projektschwerpunkte

- Mathematische Modellbildung für Bandglühöfen

- Beobachterentwurf zur Schätzung nicht messbarer Prozessgrößen

- Entwicklung einer modernen Regelungsstrategie für die Erwärmung des Bandes

Beschreibung

In der Stahlindustrie werden Durchlaufglühöfen zur Wärmebehandlung von Bandprodukten verwendet. Um einen kontinuierlichen Betrieb solcher Glühöfen zu gewährleisten, werden die Stahlbänder aneinandergeschweißt und als Endlosband durch den Ofen befördert. Die Wärmebehandlung verbraucht große Mengen an Energie, ist kostenintensiv und hat direkte Auswirkungen auf die Produktqualität.

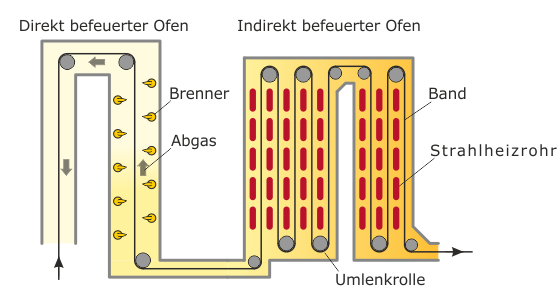

Kombiniert direkt und indirekt befeuerter Bandglühofen.

Um die hohen Anforderungen an die Qualität des Endprodukts zu erfüllen, muss jedes Band im Glühofen auf eine definierte Zieltemperatur erwärmt werden. Da es sich bei einem Glühofen um ein komplexes thermodynamisches Mehrgrößensystem mit vielfältigen Abhängigkeiten handelt, ist die Regelung der Bandtemperatur eine anspruchsvolle Aufgabe. Diese Aufgabe wird durch eine geringe Anzahl verfügbarer Messungen, Beschränkungen der Eingangs- und Prozessgrößen, einer zunehmenden Diversifikation des Produktportfolios sowie steigenden Anforderungen hinsichtlich Produktqualität und Durchsatz erschwert.

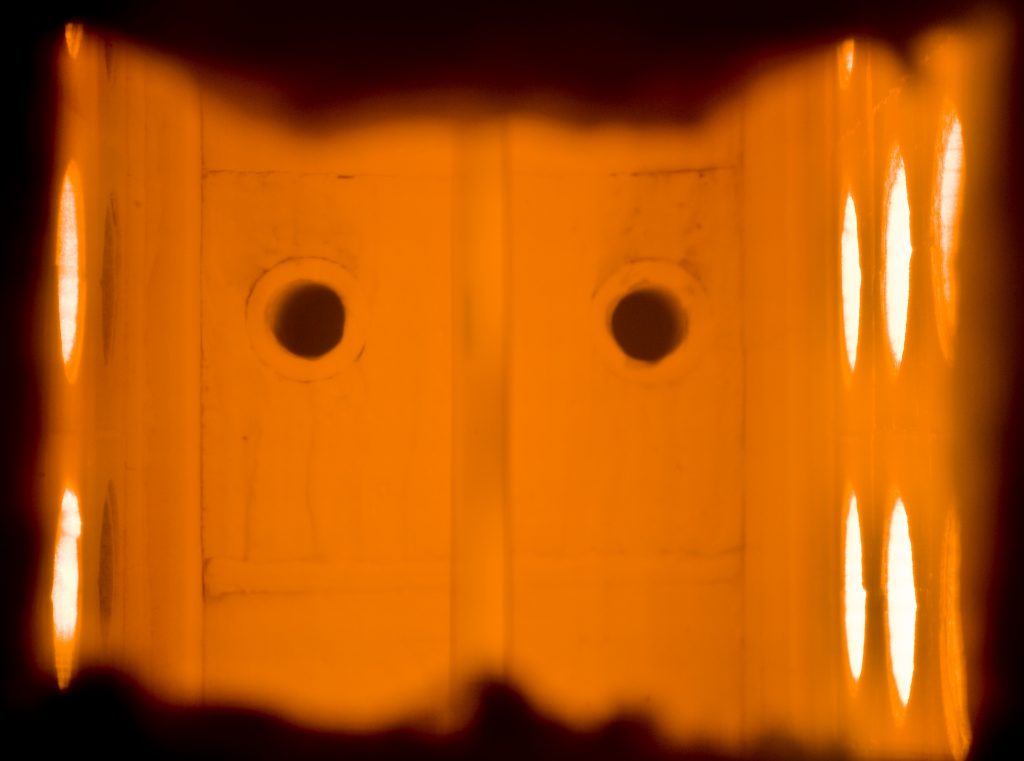

Brenner und Band im direkt befeuerten Bandglühofen, © voestalpine AG.

In diesem Projekt wurde ein optimierungsbasiertes Regelungskonzept für die Bandtemperatur in einem kombiniert direkt- und indirekt-befeuerten Glühofen entwickelt und an einer Pilotanlage der voestapline Stahl GmbH am Standort Linz umgesetzt. Der nichtlineare modellprädiktive Regler bestimmt optimale Trajektorien für die Brennstoffzufuhr und die Bandgeschwindigkeit so, dass die Bandtemperatur ihrem Sollsignal folgt. Darüber hinaus maximiert der Regler den Produktdurchsatz und minimiert den Energieverbrauch.

Kontinuierlicher Bandglühofen, © voestalpine AG.

Die Grundlage dieses Regelungskonzepts ist ein mathematisches Modell für die Bandtemperatur. Für die Formulierung dieses Modells wurden Mol-, Massen- und Enthalpiebilanzen, Konstitutivgleichungen und numerische Diskretisierungsverfahren verwendet. Zur Schätzung nicht messbarer Prozessgrößen sowie unbekannter Materialparameter, wie z.B. der Bandemissivität, wird ein ad-hoc Zustandsbeobachter verwendet.

Ausgewählte Veröffentlichungen

- S. Strommer, C. Froehlich, M. Niederer, A. Steinboeck, and A. Kugi, Modeling and Control of the Oxygen Concentration in a Post Combustion Chamber of a Gas-Fired Furnace, in Proceedings of the 20th IFAC World Congress, Toulouse, France, 2017, p. 13766–13771.

[BibTex]@InProceedings{Strommer17a, author = {Strommer, S. and Froehlich, C. and Niederer, M. and Steinboeck, A. and Kugi, A.}, title = {Modeling and Control of the Oxygen Concentration in a Post Combustion Chamber of a Gas-Fired Furnace}, booktitle = {Proceedings of the 20th IFAC World Congress}, year = {2017}, volume = {50}, number = {1}, month = {7}, pages = {13766--13771}, doi = {10.1016/j.ifacol.2017.08.1651}, address = {Toulouse, France}, issn = {2405-8963}, } - C. Fröhlich, S. Strommer, A. Steinboeck, M. Niederer, and A. Kugi, Modeling of the Media-Supply of Gas Burners of an Industrial Furnace, IEEE Transactions on Industry Applications, vol. 52, iss. 3, pp. 2664-2672, 2016.

[BibTex] [Download]@Article{Froehlich16, Title = {Modeling of the Media-Supply of Gas Burners of an Industrial Furnace}, Author = {Fr{\"o}hlich, Christoph and Strommer, S. and Steinboeck, A. and Niederer, M. and Kugi, A.}, Journal = {IEEE Transactions on Industry Applications}, Pages = {2664-2672}, Volume = {52}, Year = {2016}, Number = {3}, Doi = {10.1109/TIA.2016.2521738}, ISSN = {0093-9994}, Publisher = {IEEE}, } - F. Maislinger, M. Niederer, A. Steinboeck, S. Strommer, and A. Kugi, A Mathematical Model of a Horizontal Direct-Fired Strip Annealing Furnace, in Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM), Vienna, Austria, 2016, p. 202–207.

[BibTex]@InProceedings{Maislinger16, author = {Maislinger, F. and Niederer, M. and Steinboeck, A. and Strommer, S. and Kugi, A.}, title = {A Mathematical Model of a Horizontal Direct-Fired Strip Annealing Furnace}, booktitle = {Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM)}, year = {2016}, volume = {49}, number = {20}, month = {8}, pages = {202--207}, doi = {10.1016/j.ifacol.2016.10.121}, address = {Vienna, Austria}, issn = {2405-8963}, } - M. Niederer, S. Strommer, A. Steinboeck, and A. Kugi, Nonlinear model predictive control of the strip temperature in an annealing furnace, Journal of Process Control, vol. 48, p. 1–13, 2016.

[BibTex] [Download]@Article{Niederer16, Title = {Nonlinear model predictive control of the strip temperature in an annealing furnace}, Author = {Niederer, M. and Strommer, S. and Steinboeck, A. and Kugi, A.}, Journal = {Journal of Process Control}, Pages = {1--13}, Volume = {48}, Year = {2016}, Doi = {10.1016/j.jprocont.2016.09.012}, ISSN = {0959-1524}, } - S. Strommer, M. Niederer, A. Steinboeck, L. Jadachowski, and A. Kugi, Nonlinear observer for temperatures and emissivities in a strip annealing furnace, in Proceedings of the IEEE Industry Applications Society Annual Meeting, Portland, USA, 2016, p. 1–8.

[BibTex]@InProceedings{Strommer16a, author = {Strommer, S. and Niederer, M. and Steinboeck, A. and Jadachowski, L. and Kugi, A.}, booktitle = {Proceedings of the IEEE Industry Applications Society Annual Meeting}, title = {Nonlinear observer for temperatures and emissivities in a strip annealing furnace}, doi = {10.1109/IAS.2016.7731914}, isbn = {978-1-4799-8397-1}, pages = {1--8}, address = {Portland, USA}, month = {10}, year = {2016}, } - S. Strommer, M. Niederer, A. Steinboeck, and A. Kugi, Combustion Processes Inside a Direct-Fired Continuous Strip Annealing Furnace, in Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM), Vienna, Austria, 2016, p. 208–213.

[BibTex]@InProceedings{Strommer16, author = {Strommer, S. and Niederer, M. and Steinboeck, A. and Kugi, A.}, title = {Combustion Processes Inside a Direct-Fired Continuous Strip Annealing Furnace}, booktitle = {Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM)}, year = {2016}, volume = {49}, number = {20}, month = {8}, pages = {208--213}, doi = {10.1016/j.ifacol.2016.10.122}, address = {Vienna, Austria}, issn = {2405-8963}, } - M. Niederer, S. Strommer, A. Steinboeck, and A. Kugi, A simple control-oriented model of an indirect-fired strip annealing furnace, International Journal of Heat and Mass Transfer, vol. 78, p. 557–570, 2014.

[BibTex] [Download]@Article{Niederer14, Title = {A simple control-oriented model of an indirect-fired strip annealing furnace}, Author = {Niederer, M. and Strommer, S. and Steinboeck, A. and Kugi, A.}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {557--570}, Volume = {78}, Year = {2014}, Doi = {10.1016/j.ijheatmasstransfer.2014.06.080}, } - S. Strommer, M. Niederer, A. Steinboeck, and A. Kugi, A mathematical model of a direct-fired continuous strip annealing furnace, International Journal of Heat and Mass Transfer, vol. 69, p. 375–389, 2014.

[BibTex] [Download]@Article{Strommer14, Title = {{A mathematical model of a direct-fired continuous strip annealing furnace}}, Author = {S. Strommer and M. Niederer and A. Steinboeck and A. Kugi}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {375--389}, Volume = {69}, Year = {2014}, Doi = {10.1016/j.ijheatmasstransfer.2013.10.001}, }

Anwendungsbereiche

- Industrieöfen

- Kontinuierliche Produktionssysteme

Ansprechpartner

Univ.-Prof. Dr.techn. Andreas KugiUniv.Prof. Dr.techn. Andreas Steinböck

Status

abgeschlossenVerwandte Projekte

- Modellierung, Beobachterentwurf und Regelung von kontinuierlichen Bandbehandlungsanlagen

- Modellierung, Beobachterentwurf und Regelung von kontinuierlichen Brammenwärmöfen

- Thermisches Modell und optimale Zeitplanung des Warmwalzens

Weiterführende Links

Fördergeber

Projektpartner