28.06.2017 Nonlinear control and protection concepts for Smart Power ICs

Project focus

- Mathematical modeling of a Smart Power IC

- Development of model-based digital control and protection functions

- Implementation and verification on a testbench

Description

Smart Power ICs are used for switching medium and high current loads in low-voltage automotive and industrial applications. Figure 1 shows exemplarily the application range of the PROFET™ Smart Power IC Series from Infineon.

Application Range of the Infineon PROFET™. © Infineon Technologies AG.

A Smart Power IC combines a power switch together with integrated control and protection functions in a single IC. Nowadays these control and protection functions are usually implemented with analog circuit elements. These analog control and protection functions exhibit major drawbacks. For example their reuse for different power classes and switching loads is often not feasible without a major redesign of the analog circuit. Moreover, advanced model-based control and load estimation algorithms are hardly implementable in analog hardware.

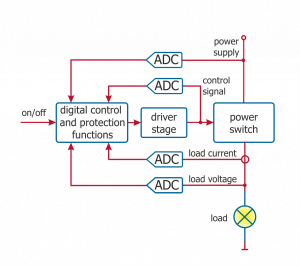

The advent of affordable System on a Chip (SoC) technology allows to overcome these drawbacks by a digital implementation of the control and protection functions. The basic concept of such a digital Smart Power IC is shown in Figure 2.

Basic concept of a digital Smart Power IC.

The characteristic quantities of the power switch (load current and voltage, power supply and the control signal) are digitized with an analog digital converter (ADC) and further processed in the microprocessor of the SoC. For the control of the power switch a digital controllable driver stage is used.

This project is concerned with the development and test bench verification of model-based digital control and protection functions for Smart Power ICs. In particular it includes the development of optimal control strategies to reduce the electromagnetic interferences in the switching process, as well as the design of new over load detection concepts and load estimation algorithms.

Selected publications

- M. Blank, T. Glück, H-P. Kreuter, and A. Kugi, Adaptive Gatestromprofile für die Schaltflankenregelung von Smart Power ICs zur EMI Reduzierung, in Tagungsband EMV-Fachtagung, Graz, Austria, 2015.

[BibTex]@InProceedings{Blank15, author = {Blank, M. and Gl\"uck, T. and Kreuter, H-P. and Kugi, A.}, title = {{A}daptive {G}atestromprofile f{\"u}r die {S}chaltflankenregelung von {S}mart {P}ower {ICs} zur {EMI} {R}eduzierung}, booktitle = {Tagungsband EMV-Fachtagung}, year = {2015}, volume = {79}, series = {OVE}, publisher = {TU Graz}, month = {4}, isbn = {978-3-85133-085-4}, address = {Graz, Austria}, } - M. Blank, T. Glück, A. Kugi, and H-P. Kreuter, Digital slew rate and S-shape control for Smart Power Switches to reduce EMI generation, IEEE Transactions on Power Electronics, vol. 30, iss. 9, p. 5170–5180, 2015.

[BibTex] [Download]@Article{Blank14b, Title = {Digital slew rate and {S-shape} control for Smart Power Switches to reduce {EMI} generation}, Author = {Blank, M. and Gl\"uck, T. and Kugi, A. and Kreuter, H-P.}, Journal = {IEEE Transactions on Power Electronics}, Pages = {5170--5180}, Volume = {30}, Year = {2015}, Number = {9}, Doi = {10.1109/TPEL.2014.2361021}, } - M. Blank, T. Glück, A. Kugi, and H-P. Kreuter, EMI Reduction for Smart Power Switches by Iterative Tracking of a Gaussian-shape Switching Transition, in Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management (PCIM), Nuremberg, Germany, 2015, p. 1361–1368.

[BibTex] [Download]@InProceedings{Blank15a, author = {Blank, M. and Gl\"uck, T. and Kugi, A. and Kreuter, H-P.}, title = {{EMI} Reduction for Smart Power Switches by Iterative Tracking of a Gaussian-shape Switching Transition}, booktitle = {Proceedings of the International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management (PCIM)}, year = {2015}, publisher = {VDE VERLAG GMBH, Berlin}, month = {5}, isbn = {978-3-8007-3924-0}, pages = {1361--1368}, url = {http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=7149176}, address = {Nuremberg, Germany}, } - M. Blank, T. Glück, A. Kugi, and H-P. Kreuter, Power Optimal Gate Current Profiles for the Slew Rate Control of Smart Power ICs, in Proceedings of the 19th IFAC World Congress, Cape Town, South Africa, 2014, p. 7190 – 7195.

[BibTex]@InProceedings{Blank14a, author = {Blank, M. and Gl\"uck, T. and Kugi, A. and Kreuter, H-P.}, title = {Power Optimal Gate Current Profiles for the Slew Rate Control of Smart Power ICs}, booktitle = {Proceedings of the 19th IFAC World Congress}, year = {2014}, month = {8}, pages = {7190 -- 7195}, doi = {10.3182/20140824-6-ZA-1003.00124}, address = {Cape Town, South Africa}, } - M. Blank, T. Glück, A. Kugi, and H. P. Kreuter, Modellierung eines Smart High-Side Power ICs, at – Automatisierungstechnik, vol. 61, iss. 12, p. 849–858, 2013.

[BibTex] [Download]@Article{Blank13, Title = {{Modellierung eines Smart High-Side Power {IC}s}}, Author = {M. Blank and T. Gl{\"u}ck and A. Kugi and H.P. Kreuter}, Journal = {at -- Automatisierungstechnik}, Pages = {849--858}, Volume = {61}, Year = {2013}, Number = {12}, Doi = {10.1515/auto.2013.1003}, } - M. Blank, T. Glück, H-P. Kreuter, and A. Kugi, Modellierung eines Smart High-Side Power ICs, in Tagungsband GMA-Fachausschuss 1.30 ”Modellbildung, Identifikation und Simulation in der Automatisierungstechnik”, Anif/Salzburg, Austria, 2012, p. 49–65.

[BibTex]@InProceedings{Blank12, author = {Blank, Mathias and Gl{\"u}ck, Tobias and Kreuter, H-P. and Kugi, Andreas}, title = {{Modellierung eines Smart High-Side Power {IC}s}}, booktitle = {Tagungsband GMA-Fachausschuss 1.30 ''Modellbildung, Identifikation und Simulation in der Automatisierungstechnik''}, year = {2012}, publisher = {Technische Universit{\"a}t Darmstadt Institut f{\"u}r Automatisierungstechnik und Mechatronik}, month = {9}, isbn = {978-3-9815012-2-3}, pages = {49--65}, address = {Anif/Salzburg, Austria}, }

Project partners and funding

26.06.2017 Backstepping-based observer design for parabolic PDEs with varying parameters

Project focus

- State estimation for scalar linear PDEs with spatially and time-varying parameters defined on a one-dimensional spatial domain and time-varying boundary conditions

- State estimation to systems governed by parabolic PDEs defined on a higher-dimensional spatial domain

- State estimation for quasi-linear parabolic PDEs with locally Lipschitz nonlinearities

- Efficient numerical implementation in view of real-time applications

Description

Model-based control and advanced process monitoring usually require full state information. This is in particular evident if control strategies are utilized by means of state feedback or if algorithms based on full state knowledge are applied to improve the insight into the system behavior, e.g., for diagnostic or error detection purposes. In general, the complete state information cannot be directly measured. This is especially true for distributed-parameter systems, i.e., systems governed by partial differential equations (PDEs). In this case, the measurement information is typically limited to a finite number of spatially discrete sensors, or for spatially higher-dimensional systems by the fact that measurements are usually available only at the boundary of the spatial domain. Therefore, an observer is required to estimate the state variables from the knowledge of measured input and output variables as well as the mathematical model of the system.

This project is concerned with the state observer design for systems governed by parabolic PDEs with boundary sensing. For this, a distributed-parameter Luenberger-type state observer is applied with observer corrections entering both the PDE and the boundary conditions. Thereby, the backstepping method is utilized and extended to determine the output injection weights to ensure the exponential decay of the resulting observer error dynamics and hence an accurate state estimation.

Selected publications

- L. Jadachowski, T. Meurer, and A. Kugi, Backstepping Observers for linear PDEs on Higher-Dimensional Spatial Domains, Automatica, vol. 51, p. 85–97, 2015.

[BibTex]@Article{Jadachowski14a, author = {Jadachowski, L. and Meurer, T. and Kugi, A.}, title = {{Backstepping Observers for linear PDEs on Higher-Dimensional Spatial Domains}}, doi = {10.1016/j.automatica.2014.10.108}, pages = {85--97}, volume = {51}, journal = {Automatica}, year = {2015}, } - L. Jadachowski, T. Meurer, and A. Kugi, Backstepping Observers for Periodic Quasi-Linear Parabolic PDEs, in Proceedings of the 19th IFAC World Congress, Cape Town, South Africa, 2014, p. 7761–7766.

[BibTex]@InProceedings{Jadachowski14, author = {Jadachowski, L. and Meurer, T. and Kugi, A.}, booktitle = {Proceedings of the 19th IFAC World Congress}, title = {Backstepping Observers for Periodic Quasi-Linear Parabolic {PDE}s}, doi = {10.3182/20140824-6-ZA-1003.01246}, pages = {7761--7766}, address = {Cape Town, South Africa}, month = {8}, year = {2014}, } - L. Jadachowski, T. Meurer, and A. Kugi, State Estimation for Parabolic PDEs with Reactive-Convective Non-Linearities, in Proceedings of European Control Conference ECC 2013, Zürich, Switzerland, 2013, p. 1603 – 1608.

[BibTex] [Download]@InProceedings{Jadachowski13, author = {L. Jadachowski and T. Meurer and A. Kugi}, title = {State Estimation for Parabolic PDEs with Reactive-Convective Non-Linearities}, booktitle = {Proceedings of European Control Conference ECC 2013}, year = {2013}, month = {7}, pages = {1603 -- 1608}, url = {http://ieeexplore.ieee.org/xpls/abs_all.jsp?arnumber=6669588}, address = {Z\"{u}rich, Switzerland}, } - L. Jadachowski, T. Meurer, and A. Kugi, An Efficient Implementation of Backstepping Observers for Time-Varying Parabolic PDEs, in Proceedings MATHMOD 2012 Vienna, Wien, Austria, 2012, p. 798–803.

[BibTex]@InProceedings{Jadachowski12, author = {L. Jadachowski and T. Meurer and A. Kugi}, title = {{An Efficient Implementation of Backstepping Observers for Time-Varying Parabolic PDEs}}, booktitle = {Proceedings MATHMOD 2012 Vienna}, year = {2012}, editor = {Troch, I. and Breitenecker, F.}, month = {2}, pages = {798--803}, doi = {10.3182/20120215-3-AT-3016.00141}, address = {Wien, Austria}, } - L. Jadachowski, T. Meurer, and A. Kugi, State Estimation for Parabolic PDEs with Varying Parameters on 3-Dimensional Spatial Domains, in Proceedings of the 18th IFAC World Congress, Milano, Italia, 2011, pp. 13338-13343.

[BibTex]@InProceedings{Jadachowski11, author = {L. Jadachowski and T. Meurer and A. Kugi}, title = {{S}tate {E}stimation for {P}arabolic {PDE}s with {V}arying {P}arameters on 3-{D}imensional {S}patial {D}omains}, booktitle = {Proceedings of the 18th IFAC World Congress}, year = {2011}, month = {8}, pages = {13338-13343}, doi = {10.3182/20110828-6-IT-1002.02964}, address = {Milano, Italia}, } - L. Jadachowski, T. Meurer, and A. Kugi, State Reconstruction in Higher Dimensional PDEs with Spatially Varying Parameters, PAMM, Proceedings in Applied Mathematics and Mechanics, vol. 11, iss. 1, p. 813–814, 2011.

[BibTex]@Article{Jadachowski11a, Title = {{State Reconstruction in Higher Dimensional PDEs with Spatially Varying Parameters}}, Author = {L. Jadachowski and T. Meurer and A. Kugi}, Journal = {PAMM, Proceedings in Applied Mathematics and Mechanics}, Pages = {813--814}, Volume = {11}, Year = {2011}, Number = {1}, Doi = {10.1002/pamm.201110395}, }

Applications

- State estimation for heating-up and cooling-down processes in steel industry

- System diagnostics and error detection in fixed-bed tubular reactors in chemical engineering

Funding

TU Wien Doktorandenkolleg PDETech

Partners

Prof. Dr.-Ing. habil. Thomas Meurer

20.06.2017 Flatness control in heavy plate rolling

Project focus

- Development of models of the visco-plastic material deformation in the roll gap

- Modeling of flatness defects occurring in heavy plate rolling

- Control design for improved flatness accuracy

Description

In heavy plate rolling, the customer demands on product thickness and flatness quality steadily increase. The quality is primarily influenced by the rolling process at reversing mill stands. Here the heavy plates are rolled out to a certain product thickness in consecutive passes. To increase the product quality, physical models serve as a basis for optimized control concepts.

Heavy plate with flatness defect (ski), © Dillinger Hüttenwerke AG.

To achieve the desired plate thickness, a precise product tracking of the heavy plate is necessary. To this end, an analytical forward slip model based on visco-plastic material behavior is deduced. The resulting partial differential equations are solved by appropriate coordinate transformations to obtain closed form solutions.

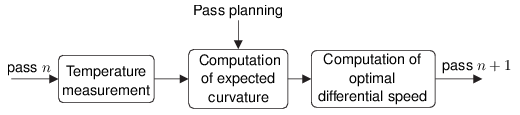

Computational scheme for reducing ski effects.

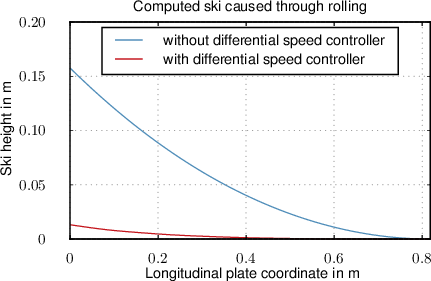

When heavy plates are rolled, an unwanted bending of the plate ends may occur. This flatness defect is called ski-effect, cf. Fig. 1. Asymmetric rolling conditions (amongst others temperature and friction) with respect to the plates mid-plane cause this phenomenon. Using the Upper Bound Method, a semi-analytical model can be obtained to describe the ski formation.

Ski simulation results for a temperature difference of 20 K between bottom and top plate side.

Based on the ski model, nonlinear control strategies are designed to improve the flatness quality. In particular, a MIMO-control concept for the main drives of the rolling mill is developed to control the circumferential speed difference between the upper and lower work roll. By means of the semi-analytical ski-model the necessary speed difference for avoiding temperature-provoked ski-ends is computed.

Selected publications

- T. Kiefer, R. Heeg, and A. Kugi, Modellbasierte Dicken- und Ebenheitsregelung in Grobblechwalzwerken, at – Automatisierungstechnik, vol. 56, iss. 8, p. 416–426, 2008.

[BibTex] [Download]@Article{Kiefer08b, Title = {Modellbasierte {D}icken- und {E}benheitsregelung in {G}robblechwalzwerken}, Author = {T. Kiefer and R. Heeg and A. Kugi}, Journal = {at -- Automatisierungstechnik}, Pages = {416--426}, Volume = {56}, Year = {2008}, Number = {8}, Doi = {10.1524/auto.2008.0720}, } - T. Kiefer and A. Kugi, Model-based control in front-end bending in hot rolling processes, in Proceedings of the 17th IFAC World Congress, Seoul, Korea, 2008, p. 1645–1650.

[BibTex]@InProceedings{Kiefer08, author = {T. Kiefer and A. Kugi}, title = {Model-based control in front-end bending in hot rolling processes}, booktitle = {Proceedings of the 17th IFAC World Congress}, year = {2008}, month = {7}, pages = {1645--1650}, doi = {10.3182/20080706-5-KR-1001.00280}, address = {Seoul, Korea}, } - T. Kiefer and A. Kugi, An Analytical Approach for Modelling Asymmetrical Hot Rolling of Heavy Plates, Mathematical and Computer Modelling of Dynamical Systems, vol. 14, iss. 3, p. 249–267, 2008.

[BibTex] [Download]@Article{Kiefer08a, Title = {An Analytical Approach for Modelling Asymmetrical Hot Rolling of Heavy Plates}, Author = {T. Kiefer and A. Kugi}, Journal = {Mathematical and Computer Modelling of Dynamical Systems}, Pages = {249--267}, Volume = {14}, Year = {2008}, Number = {3}, Doi = {10.1080/13873950701844915}, } - T. Kiefer and A. Kugi, Modelling and Control of Front End Bending in Heavy Plate Mills, in Proceedings of the 12th IFAC Symposium on Automation in Mining, Mineral and Metal Processing, Quebec City, Canada, 2007, p. 231–236.

[BibTex]@InProceedings{Kiefer07, author = {T. Kiefer and A. Kugi}, title = {Modelling and Control of Front End Bending in Heavy Plate Mills}, booktitle = {Proceedings of the 12th IFAC Symposium on Automation in Mining, Mineral and Metal Processing}, year = {2007}, month = {8}, pages = {231--236}, doi = {10.3182/20070821-3-CA-2919.00034}, address = {Quebec City, Canada}, }

Applications

- Automation of rolling mills

20.06.2017 Modeling and control of hot levelers

Project focus

- Modeling, identification and analysis of the mechanical and hydraulic components of the leveler

- Optimal, active compensation of the elastic deformation

- Design of control strategies for the dynamic positioning of the leveler

Description

Hot levelers are used in hot rollings mills for steel plates. After rolling and cooling, a leveling machine reduces remaining flatness errors and residual stresses in the plates. Between the work rolls of the hot leveler, the plates undergo plastic deformations through alternating excessive bending.

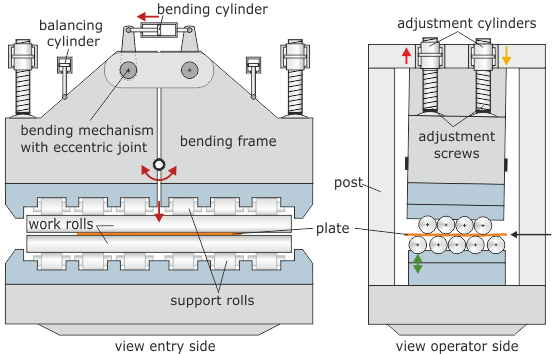

Hot leveler with bending mechanism.

The leveling forces can reach several meganewtons and lead to deformations of the leveler in the range of several millimeters. For quality reasons, these deformations have to be compensated, e.g., by means of actuators or a bending mechanism. At the same time, overloading the leveler must be avoided.

The modeling and analysis of the mechanical and hydraulic configuration of the leveler are of interest. Essential parts of the mathematical model are the elastic deflection of the machine as well as friction forces which occur in the hydraulic actuators and the joints of the bending mechanism.

The work rolls are modeled as Euler-Bernoulli beams. They are elastically supported by the support rolls, the sub-frames, and the posts, where the deflection models of these components are represented by compliance matrices. The deflection model was validated by measurements with instrumented plates. A reduced finite-dimensional model is used to determine an optimal deflection compensation. By means of an optimization algorithm the adjustment of the actuators is calculated such that the desired plate curvature is optimally reached. With the optimization approach the mechanical load is directly constrained and thus overloading the leveler is avoided. For the calculation of the leveling load a nonlinear leveling model is used.

The precise adjustment of the rolls by means of the bending mechanism is crucial for an effective deflection compensation. Based on a validated mathematical dynamical model of the mechanism, a control law was developed, which reliably adjusts the rolls even under friction and operating loads.

The developed solution has been successfully implemented at an industrial hot leveler for heavy plates.

Selected publications

- R. Brauneis, M. Baumgart, A. Steinboeck, and A. Kugi, Deflection Model Of A Multi-Actuator Gap Leveler, in Proceedings of the 20th IFAC World Congress, Toulouse, France, 2017, pp. 11295-11300.

[BibTex] [Download]@InProceedings{Brauneis17, author = {Brauneis, R. and Baumgart, M. and Steinboeck, A. and Kugi, A.}, title = {Deflection Model Of A Multi-Actuator Gap Leveler}, booktitle = {Proceedings of the 20th IFAC World Congress}, year = {2017}, volume = {50}, number = {1}, month = {7}, pages = {11295-11300}, doi = {10.1016/j.ifacol.2017.08.1647}, address = {Toulouse, France}, issn = {2405-8963}, } - M. Baumgart, A. Steinboeck, T. Kiefer, and A. Kugi, Modelling and experimental validation of the deflection of a leveller for hot heavy plates, Mathematical and Computer Modelling of Dynamical Systems, vol. 21, iss. 3, p. 202–227, 2015.

[BibTex] [Download]@Article{Baumgart15a, Title = {Modelling and experimental validation of the deflection of a leveller for hot heavy plates}, Author = {Baumgart, M. and Steinboeck, A. and Kiefer, T. and Kugi, A.}, Journal = {Mathematical and Computer Modelling of Dynamical Systems}, Pages = {202--227}, Volume = {21}, Year = {2015}, Number = {3}, Doi = {10.1080/13873954.2014.941881}, } - M. Baumgart, A. Steinboeck, A. Kugi, G. Raffin-Peyloz, L. Irastroza, and T. Kiefer, Optimal Active Deflection Compensation of a Hot Leveler, in Proceedings of the IFAC Workshop on Automation in the Mining, Mineral and Metal Industries, Gifu, Japan, 2012, p. 30 – 35.

[BibTex]@InProceedings{Baumgart12, author = {M. Baumgart and A. Steinboeck and A. Kugi and G. Raffin-Peyloz and L. Irastroza and T. Kiefer}, title = {{O}ptimal {A}ctive {D}eflection {C}ompensation of a {H}ot {L}eveler}, booktitle = {Proceedings of the IFAC Workshop on Automation in the Mining, Mineral and Metal Industries}, year = {2012}, month = {9}, pages = {30 -- 35}, doi = {10.3182/20120910-3-JP-4023.00009}, address = {Gifu, Japan}, } - M. Baumgart, A. Steinboeck, A. Kugi, B. Douanne, G. Raffin-Peyloz, L. Irastroza, and T. Kiefer, Modeling and Active Compensation of the Compliance of a Hot Leveler, steel research international, vol. Special Edition ICTP2011, p. 337–342, 2011.

[BibTex]@Article{Baumgart11a, Title = {{Modeling and Active Compensation of the Compliance of a Hot Leveler}}, Author = {M. Baumgart and A. Steinboeck and A. Kugi and B. Douanne and G. Raffin-Peyloz and L. Irastroza and T. Kiefer}, Journal = {steel research international}, Pages = {337--342}, Volume = {Special Edition ICTP2011}, Year = {2011}, } - M. Baumgart, A. Steinboeck, A. Kugi, G. Raffin-Peyloz, B. Douanne, L. Irastorza, and T. Kiefer, Active compliance compensation of a hot leveler, in Proceedings of the 4th International Conference on Modelling and Simulation of Metallurgical Processes in Steelmaking, STEELSIM, METEC InSteelCon 2011, Düsseldorf, Germany, 2011.

[BibTex]@InProceedings{Baumgart11, author = {M. Baumgart and A. Steinboeck and A. Kugi and G. Raffin-Peyloz and B. Douanne and L. Irastorza and T. Kiefer}, title = {Active compliance compensation of a hot leveler}, booktitle = {Proceedings of the 4th International Conference on Modelling and Simulation of Metallurgical Processes in Steelmaking, STEELSIM, METEC InSteelCon 2011}, year = {2011}, month = {6}, address = {D\"usseldorf, Germany}, }

Applications

- Rolling mill automation

- Press equipment/forming machinery

19.06.2017 Modeling, observer design, control, and optimization of strip annealing furnaces

Project focus

- Mathematical modeling of a strip annealing furnace

- Observer design for unknown process variables

- Development of a control strategy for accurate heating of the strip

Description

In the steel industry, continuous strip annealing furnaces are used for the heat treatment of strip products. To ensure a continuous operation of the furnace, the strips are welded together to form an endless strip. The heat treatment requires a large amount of energy, is cost-intensive, and has a direct impact on the product quality.

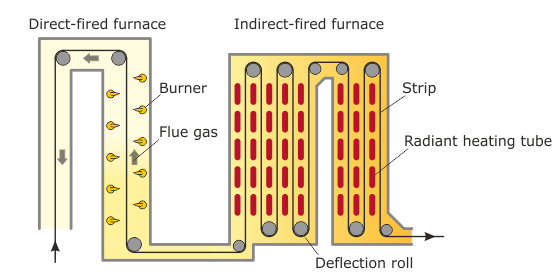

Combined direct- and indirect-fired furnace.

To meet the high demands on the quality of the final product, the strip has to be heated to a predefined target temperature while it moves through the furnace. Since an annealing furnace is a complex thermodynamic system with multiple inputs, multiple outputs and diverse interdependencies, strip temperature control is a challenging task. This task is further complicated by a small number of available measurements, restrictions on the inputs and the process quantities, an increasing diversification of the product portfolio as well as increasing demands in terms of product quality and throughput.

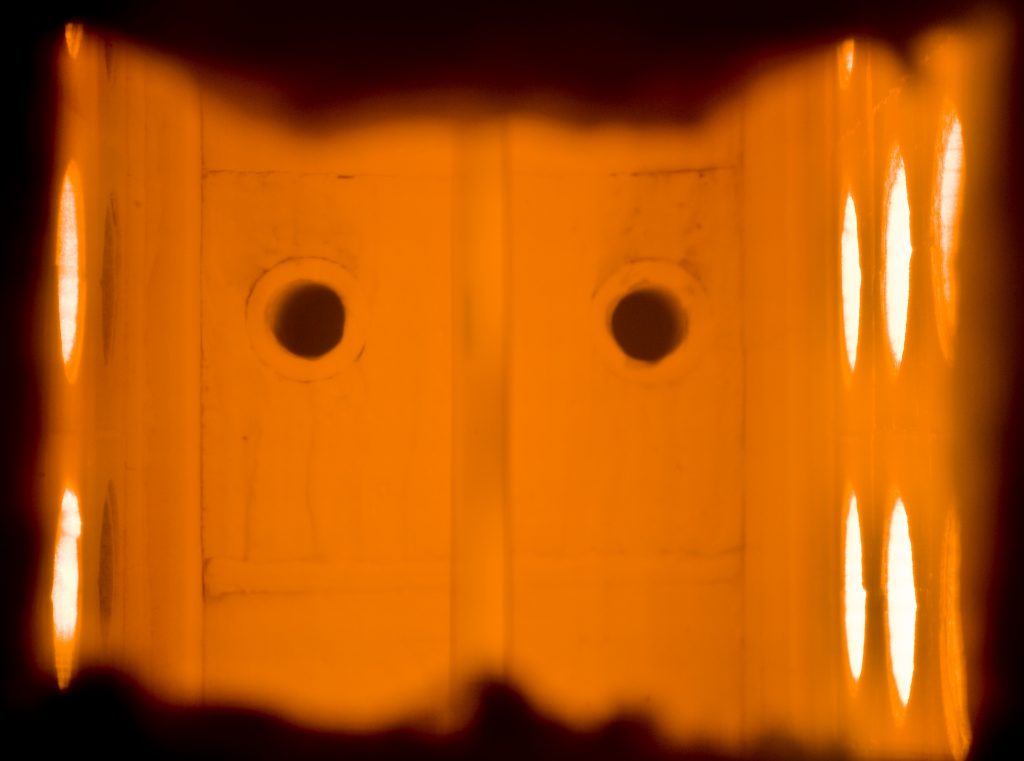

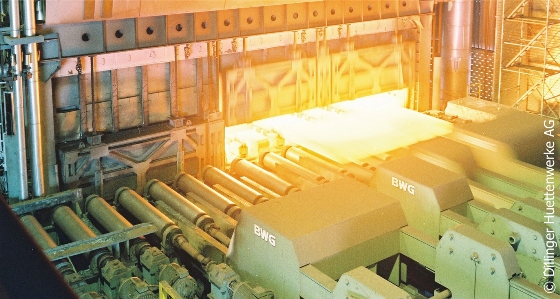

Burners and strip in the direct-fired strip annealing furnace, © voestalpine AG.

In this project, an optimization-based control concept for the strip temperature of a combined direct- and indirect-fired annealing furnace was developed and implemented at a pilot plant of voestalpine Stahl Gmbh in Linz, Austria. The nonlinear model predictive controller selects optimal values for both the fuel supply and the strip velocity so that the strip temperature follows its desired trajectory. In addition, the controller maximizes the product throughput and minimizes the energy consumption.

Continuous strip annealing furnace, © voestalpine AG.

The basis of the controller for the strip temperature is a mathematical model of the considered annealing furnace. Mol, mass, and enthalpy balances, constitutive equations, and numerical discretization methods were used to formulate this model. An ad-hoc state estimator is used to estimate process quantities and material parameters, e.g., the strip emissivity, which cannot be directly measured.

Selected publications

- S. Strommer, C. Froehlich, M. Niederer, A. Steinboeck, and A. Kugi, Modeling and Control of the Oxygen Concentration in a Post Combustion Chamber of a Gas-Fired Furnace, in Proceedings of the 20th IFAC World Congress, Toulouse, France, 2017, p. 13766–13771.

[BibTex]@InProceedings{Strommer17a, author = {Strommer, S. and Froehlich, C. and Niederer, M. and Steinboeck, A. and Kugi, A.}, title = {Modeling and Control of the Oxygen Concentration in a Post Combustion Chamber of a Gas-Fired Furnace}, booktitle = {Proceedings of the 20th IFAC World Congress}, year = {2017}, volume = {50}, number = {1}, month = {7}, pages = {13766--13771}, doi = {10.1016/j.ifacol.2017.08.1651}, address = {Toulouse, France}, issn = {2405-8963}, } - C. Fröhlich, S. Strommer, A. Steinboeck, M. Niederer, and A. Kugi, Modeling of the Media-Supply of Gas Burners of an Industrial Furnace, IEEE Transactions on Industry Applications, vol. 52, iss. 3, pp. 2664-2672, 2016.

[BibTex] [Download]@Article{Froehlich16, Title = {Modeling of the Media-Supply of Gas Burners of an Industrial Furnace}, Author = {Fr{\"o}hlich, Christoph and Strommer, S. and Steinboeck, A. and Niederer, M. and Kugi, A.}, Journal = {IEEE Transactions on Industry Applications}, Pages = {2664-2672}, Volume = {52}, Year = {2016}, Number = {3}, Doi = {10.1109/TIA.2016.2521738}, ISSN = {0093-9994}, Publisher = {IEEE}, } - F. Maislinger, M. Niederer, A. Steinboeck, S. Strommer, and A. Kugi, A Mathematical Model of a Horizontal Direct-Fired Strip Annealing Furnace, in Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM), Vienna, Austria, 2016, p. 202–207.

[BibTex]@InProceedings{Maislinger16, author = {Maislinger, F. and Niederer, M. and Steinboeck, A. and Strommer, S. and Kugi, A.}, title = {A Mathematical Model of a Horizontal Direct-Fired Strip Annealing Furnace}, booktitle = {Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM)}, year = {2016}, volume = {49}, number = {20}, month = {8}, pages = {202--207}, doi = {10.1016/j.ifacol.2016.10.121}, address = {Vienna, Austria}, issn = {2405-8963}, } - M. Niederer, S. Strommer, A. Steinboeck, and A. Kugi, Nonlinear model predictive control of the strip temperature in an annealing furnace, Journal of Process Control, vol. 48, p. 1–13, 2016.

[BibTex] [Download]@Article{Niederer16, Title = {Nonlinear model predictive control of the strip temperature in an annealing furnace}, Author = {Niederer, M. and Strommer, S. and Steinboeck, A. and Kugi, A.}, Journal = {Journal of Process Control}, Pages = {1--13}, Volume = {48}, Year = {2016}, Doi = {10.1016/j.jprocont.2016.09.012}, ISSN = {0959-1524}, } - S. Strommer, M. Niederer, A. Steinboeck, L. Jadachowski, and A. Kugi, Nonlinear observer for temperatures and emissivities in a strip annealing furnace, in Proceedings of the IEEE Industry Applications Society Annual Meeting, Portland, USA, 2016, p. 1–8.

[BibTex]@InProceedings{Strommer16a, author = {Strommer, S. and Niederer, M. and Steinboeck, A. and Jadachowski, L. and Kugi, A.}, booktitle = {Proceedings of the IEEE Industry Applications Society Annual Meeting}, title = {Nonlinear observer for temperatures and emissivities in a strip annealing furnace}, doi = {10.1109/IAS.2016.7731914}, isbn = {978-1-4799-8397-1}, pages = {1--8}, address = {Portland, USA}, month = {10}, year = {2016}, } - S. Strommer, M. Niederer, A. Steinboeck, and A. Kugi, Combustion Processes Inside a Direct-Fired Continuous Strip Annealing Furnace, in Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM), Vienna, Austria, 2016, p. 208–213.

[BibTex]@InProceedings{Strommer16, author = {Strommer, S. and Niederer, M. and Steinboeck, A. and Kugi, A.}, title = {Combustion Processes Inside a Direct-Fired Continuous Strip Annealing Furnace}, booktitle = {Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM)}, year = {2016}, volume = {49}, number = {20}, month = {8}, pages = {208--213}, doi = {10.1016/j.ifacol.2016.10.122}, address = {Vienna, Austria}, issn = {2405-8963}, } - M. Niederer, S. Strommer, A. Steinboeck, and A. Kugi, A simple control-oriented model of an indirect-fired strip annealing furnace, International Journal of Heat and Mass Transfer, vol. 78, p. 557–570, 2014.

[BibTex] [Download]@Article{Niederer14, Title = {A simple control-oriented model of an indirect-fired strip annealing furnace}, Author = {Niederer, M. and Strommer, S. and Steinboeck, A. and Kugi, A.}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {557--570}, Volume = {78}, Year = {2014}, Doi = {10.1016/j.ijheatmasstransfer.2014.06.080}, } - S. Strommer, M. Niederer, A. Steinboeck, and A. Kugi, A mathematical model of a direct-fired continuous strip annealing furnace, International Journal of Heat and Mass Transfer, vol. 69, p. 375–389, 2014.

[BibTex] [Download]@Article{Strommer14, Title = {{A mathematical model of a direct-fired continuous strip annealing furnace}}, Author = {S. Strommer and M. Niederer and A. Steinboeck and A. Kugi}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {375--389}, Volume = {69}, Year = {2014}, Doi = {10.1016/j.ijheatmasstransfer.2013.10.001}, }

Applications

- Industrial furnaces

- Continuous production systems

16.06.2017 Modeling and control of a four-high heavy plate rolling mill

Project focus

- Modeling, identification, and analysis of mechanical and hydraulic components of a finishing mill

- Control of heavy plate mills (feedforward thickness control)

- Online-Adaptation of model parameters for model based control

Description

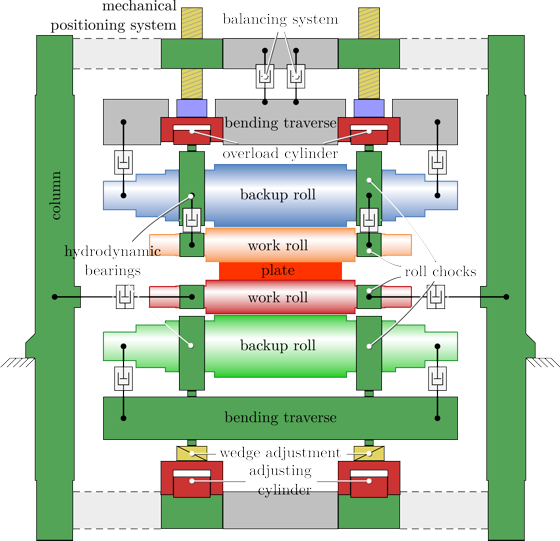

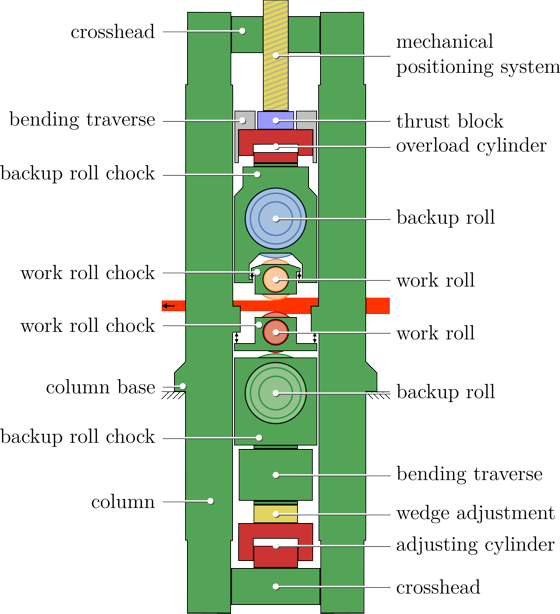

In heavy plate rolling, the heated plates are plastically deformed by rolling mills. For this task, reversing four-high mill stands consisting of two work-rolls and two backup-rolls are often used. The plate is deformed between the two work-rolls in several rolling passes. The high rolling forces during the deformation cause the work-rolls to bend which in turn yields a nonuniform thickness profile of the plate. The two backup-rolls reduce the bending deflection of the work-rolls. Additionally, the mills are equipped with devices for bending compensation like hydraulic bending systems and/or specifically shaped rolls (CVC-rolls). These measures shall ensure a plain roll gap and thus a uniform lateral thickness profile of the final product.

Four-high rolling mill, © Dillinger Hüttenwerke AG.

During the rolling process, the mill is loaded with forces up to 90 MN, which cause elastic deformations of the mill up to 13 mm. The total deflection consists of the elastic deformation of the mill, the bending deflection of the rolls, and the compression of the rolls. As thickness tolerances of 0.1 mm have to be met, it is necessary to compensate the deflection. Furthermore, the mill has to be set up in such a way that the roll gap between the two work-rolls is as flat as possible to ensure a uniform exit thickness of the plate in lateral direction. However, the exit thickness of the plate cannot be reliably measured close to the roll gap due to the hostile environment (heat, steam). The thickness measurement, which is located some meters away from the mill stand, is not useful for real-time thickness control due to the time lag. Thus, the exit thickness has to be calculated with a mathematical model. The model has to include the compliance of the hydraulic and the mechanical components of the mill stand and – especially for the calculation of the thickness profile in lateral direction – the bending and the compression of the rolls. The model results may then be used for real-time control.

Setup of a four-high finishing mill – front view.

Due to the dimensions of the rolls, a deflection model based on the Timoshenko beam theory is used. To fully describe the problem, the loads of the rolls and the boundary conditions have to be determined.

The rolling force is the force between the two work-rolls required for the plastic deformation of the plate. This force depends on the material of the plate, the rolling velocity, the temperature distribution as well as the entry and exit thickness profile of the plate. As the exit thickness depends on the bending of the two work-rolls, a nonlinear coupling of the differential equations of the work-rolls is obtained.

Similar considerations may be made about the contact of the work- and backup-rolls. Generally, there is a nonlinear relation between the contact force and the bending of the work- and backup-rolls.

To determine the boundary conditions, the distance between the backup-roll journals has to be identified. Apart from a calibration of the model, this requires the calculation of the deflection of the mill stand which depends on the rolling force. Moreover, friction forces between the roll chocks and the columns have to be taken into account. Furthermore, the position of the backup-roll journals in the hydrodynamic bearings, which depends nonlinearly on the rolling force and the rolling velocity, has to be determined.

A 2-point boundary value problem consisting of 16 coupled nonlinear differential equations has to be solved. As the model is to be used for real-time control, its calculation time must not exceed the sampling period of the system.

The developed solution has been successfully verified with measurement data from an industrial finishing mill.

Setup of a four-high finishing mill – side view.

If such a model is used in a conventional feedback controller, it is difficult to compensate for fast variations of the entry thickness and the yield strength of the plate due to the limited response characteristic of the positioning system and the closed-loop control. Thus, strategies to estimate the entry thickness and yield strength profile during a pass here developed. By applying these profiles in the sense of a feedforward control to the next pass, it is possible to partially compensate the thickness deviations in the entry profiles.

The developed solutions were tested in computer simulations before they were applied to an industrial finishing mill stand where they are further developed successfully.

Selected publications

- T. König, Entwicklung, Parametrierung und Online-Adaption eines mathematischen Modells eines Walzgerüstes beim Warmwalzen, A. Kugi and K. Schlacher, Eds., Aachen: Shaker Verlag, 2014, vol. 22.

[BibTex]@Book{Koenig14, Title = {Entwicklung, {P}arametrierung und {O}nline-{A}daption eines mathematischen {M}odells eines {W}alzger{\"u}stes beim {W}armwalzen}, Author = {K{\"o}nig, T.}, Editor = {A. Kugi and K. Schlacher}, Publisher = {Shaker Verlag}, Year = {2014}, Address = {Aachen}, Series = {Modellierung und Regelung komplexer dynamischer Systeme}, Volume = {22}, ISBN = {978-3-8440-3224-6}, Organization = {Institute f{\"u}r Automatisierungs- und Regelungstechnik (TU Wien) und Regelungstechnik und Prozessautomatisierung (JKU Linz)}, } - T. König, A. Steinboeck, and A. Kugi, Online Calibration of a Mathematical Model for the Deflection of a Rolling Mill, in Proceedings of Rolling 2013, Venezia, Italy, 2013, p. 1–12.

[BibTex]@InProceedings{Konig13, author = {T. K{\"o}nig and A. Steinboeck and A. Kugi}, title = {{{O}nline {C}alibration of a {M}athematical {M}odel for the {D}eflection of a {R}olling {M}ill}}, booktitle = {Proceedings of Rolling 2013}, year = {2013}, month = {6}, pages = {1--12}, address = {Venezia, Italy}, } - T. König, A. Steinboeck, A. Kugi, R. Heeg, and T. Kiefer, Deflection and bending model of a four-high mill stand for heavy plate rolling, in Proceedings of the 4th International Conference on Modelling and Simulation of Metallurgical Processes in Steelmaking, STEELSIM, METEC InSteelCon 2011, Düsseldorf, Germany, 2011.

[BibTex]@InProceedings{Koenig11, author = {T. K\"onig and A. Steinboeck and A. Kugi and R. Heeg and T. Kiefer}, title = {Deflection and bending model of a four-high mill stand for heavy plate rolling}, booktitle = {Proceedings of the 4th International Conference on Modelling and Simulation of Metallurgical Processes in Steelmaking, STEELSIM, METEC InSteelCon 2011}, year = {2011}, month = {6}, address = {D\"usseldorf, Germany}, } - R. Heeg, Modellierung und Dickenregelung beim Warmwalzen, A. Kugi and K. Schlacher, Eds., Aachen: Shaker Verlag, 2009, vol. 5.

[BibTex]@Book{Heeg09, Title = {Modellierung und Dickenregelung beim Warmwalzen}, Author = {R. Heeg}, Editor = {A. Kugi and K. Schlacher}, Publisher = {Shaker Verlag}, Year = {2009}, Address = {Aachen}, Series = {Modellierung und Regelung komplexer dynamischer Systeme}, Volume = {5}, ISBN = {978-3-8322-7871-7}, } - T. König, Mathematische Modelle zur Berechnung der Auffederung eines Fertiggerüstes, 2008.

[BibTex]@Mastersthesis{koenig08, Title = {Mathematische Modelle zur Berechnung der Auffederung eines Fertigger{\"u}stes}, Author = {K{\"o}nig, T.}, School = {Vienna University of Technology}, Year = {2008}, } - R. Heeg, T. Kiefer, and A. Kugi, Control of Plate Thickness in Heavy Plate Mills: A New Perspective, in Proceedings of the 12th IFAC Symposium on Automation in Mining, Mineral and Metal Processing, Quebec City, Canada, 2007, p. 107–112.

[BibTex]@InProceedings{Heeg07, author = {R. Heeg and T. Kiefer and A. Kugi}, title = {Control of Plate Thickness in Heavy Plate Mills: A New Perspective}, booktitle = {Proceedings of the 12th IFAC Symposium on Automation in Mining, Mineral and Metal Processing}, year = {2007}, month = {8}, pages = {107--112}, doi = {10.3182/20070821-3-CA-2919.00016}, address = {Quebec City, Canada}, }

Applications

- Rolling mill automation

- Plastic deformation process

- Hot plate rolling

14.06.2017 Lateral guiding and shape control in heavy plate rolling

Project focus

- Modelling of shape evolution and off-centering of heavy plates

- Development of a realtime plate contour measurement system

- Design of control strategies for reduction of shape errors

Description

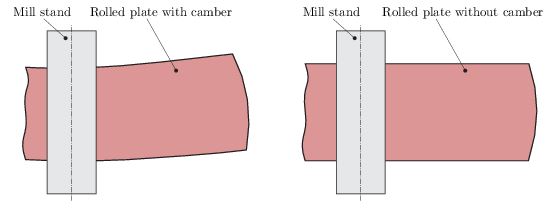

In steel mills, slabs are rolled out to heavy plates with a certain plate thickness using reversing mills. During this process, unwanted geometrical deviations with respect to the vertical axis of the plate (camber) can occur. Furthermore, the plate movement through the rolling gap can differ from the desired straight movement. Steadily increasing demands on the product quality require to minimize these imperfections.

Heavy plate rolling with and without camber (top view).

To simulate the occurrence of camber during the rolling process, tailored mathematical models are used. A formulation based on continuum mechanics predicts the residual stresses and the evolution of the plate contour using the plastical deformation caused in the rolling gap. By means of these models, the impact of several factors on the formation of camber can be analyzed and potentials for optimizing the mill stand can be identified.

Quarto reversing mill, © Dillinger Hüttenwerke AG.

For the detection and characterization of camber, a vision based system is used. In addition to the shape of the plate, its movement during the rolling pass is determined in realtime. The implemented measurement methods have to withstand unfavourable environmental conditions. Furthermore, ensuring a realtime capable measurement is another challenge.

Based on the camber model, control and optimization algorithms for the reduction of an existing camber are designed. To this end, several control inputs of the mill stand can be used to ensure that additional product requirements (e.g. plate thickness) are satisfied and that off-centering is avoided.

The developed solutions have been successfully implemented on a heavy plate rolling mill and are now permanently used.

Selected publications

- F. Schausberger, A. Steinboeck, and Kugi, Optimization-based reduction of contour errors of heavy plates in hot rolling, Journal of Process Control, vol. 47, p. 150–160, 2016.

[BibTex] [Download]@Article{Schausberger16a, Title = {Optimization-based reduction of contour errors of heavy plates in hot rolling}, Author = {Schausberger, F. and Steinboeck, A. and Kugi}, Journal = {Journal of Process Control}, Pages = {150--160}, Volume = {47}, Year = {2016}, Doi = {10.1016/j.jprocont.2016.09.010}, ISSN = {0959-1524}, } - F. Schausberger, A. Steinboeck, A. Kugi, M. Jochum, D. Wild, and T. Kiefer, Vision-Based Material Tracking in Heavy-Plate Rolling, in Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM), Vienna, Austria, 2016, p. 108–113.

[BibTex] [Download]@InProceedings{Schausberger16, author = {Schausberger, F. and Steinboeck, A. and Kugi, A. and Jochum, M. and Wild, D. and Kiefer, T.}, title = {Vision-Based Material Tracking in Heavy-Plate Rolling}, booktitle = {Proceedings of the 17th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral and Metal Processing (MMM)}, year = {2016}, volume = {49}, number = {20}, month = {8}, pages = {108--113}, doi = {10.1016/j.ifacol.2016.10.105}, address = {Vienna, Austria}, issn = {2405-8963}, } - F. Schausberger, K. Speicher, A. Steinboeck, M. Jochum, and A. Kugi, Two Illustrative Examples to Show the Potential of Thermography for Process Monitoring and Control in Hot Rolling, in Proceedings of the 4th IFAC Workshop on Mining, Mineral and Metal Processing (MMM), Oulu, Finland, 2015, p. 48–53.

[BibTex] [Download]@InProceedings{Schausberger15c, author = {Schausberger, F. and Speicher, K. and Steinboeck, A. and Jochum, M. and Kugi, A.}, title = {Two Illustrative Examples to Show the Potential of Thermography for Process Monitoring and Control in Hot Rolling}, booktitle = {Proceedings of the 4th IFAC Workshop on Mining, Mineral and Metal Processing (MMM)}, year = {2015}, volume = {48}, number = {17}, month = {8}, pages = {48--53}, doi = {10.1016/j.ifacol.2015.10.076}, address = {Oulu, Finland}, issn = {2405-8963}, } - F. Schausberger, A. Steinboeck, and A. Kugi, Mathematical modeling of the contour evolution of heavy plates in hot rolling, Applied Mathematical Modelling, vol. 39, p. 4534–4547, 2015.

[BibTex] [Download]@Article{Schausberger15, Title = {Mathematical modeling of the contour evolution of heavy plates in hot rolling}, Author = {Schausberger, F. and Steinboeck, A. and Kugi, A.}, Journal = {Applied Mathematical Modelling}, Pages = {4534--4547}, Volume = {39}, Year = {2015}, Doi = {10.1016/j.apm.2015.01.017}, } - F. Schausberger, A. Steinboeck, and A. Kugi, Optimization-based estimator for the contour and movement of heavy plates in hot rolling, Journal of Process Control, vol. 29, p. 23–32, 2015.

[BibTex] [Download]@Article{Schausberger15a, Title = {Optimization-based estimator for the contour and movement of heavy plates in hot rolling}, Author = {Schausberger, F. and Steinboeck, A. and Kugi, A.}, Journal = {Journal of Process Control}, Pages = {23--32}, Volume = {29}, Year = {2015}, Doi = {10.1016/j.jprocont.2015.03.006}, } - F. Schausberger, A. Steinboeck, and A. Kugi, Modellbasierte Optimierung und Regelung der Produktkontur beim Warmwalzen, e & i Elektrotechnik und Informationstechnik, vol. 132, iss. 4–5, p. 221–229, 2015.

[BibTex] [Download]@Article{Schausberger15d, Title = {Modellbasierte Optimierung und Regelung der Produktkontur beim Warmwalzen}, Author = {Schausberger, F. and Steinboeck, A. and Kugi, A.}, Journal = {e {\&} i Elektrotechnik und Informationstechnik}, Pages = {221--229}, Volume = {132}, Year = {2015}, Number = {4--5}, Doi = {10.1007/s00502-015-0309-2}, } - F. Schausberger, A. Steinboeck, A. Kugi, M. Jochum, and D. Wild, Estimation of the thickness asymmetry using models for the contour evolution and vision-based measurements of plates in hot rolling, in Proceedings of METEC and 2nd European Steel Technology and Application Days (ESTAD), Düsseldorf, Germany, 2015.

[BibTex]@InProceedings{Schausberger15b, author = {Schausberger, F. and Steinboeck, Andreas and Kugi, Andreas and Jochum, M. and Wild, D.}, title = {Estimation of the thickness asymmetry using models for the contour evolution and vision-based measurements of plates in hot rolling}, booktitle = {Proceedings of METEC and 2nd European Steel Technology and Application Days (ESTAD)}, year = {2015}, month = {6}, address = {D{\"u}sseldorf, Germany}, } - F. Schausberger, A. Steinboeck, and A. Kugi, Modellierung der Konturentwicklung von Flachprodukten beim Walzen, in Tagungsband GMA-Fachausschuss 1.30 “Modellbildung, Identikation und Simulation in der Automatisierungstechnik”, Anif/Salzburg, Austria, 2013, p. 42–59.

[BibTex]@InProceedings{Schausberger13, author = {F. Schausberger and A. Steinboeck and A. Kugi}, title = {{Modellierung der Konturentwicklung von Flachprodukten beim Walzen}}, booktitle = {Tagungsband GMA-Fachausschuss 1.30 "Modellbildung, Identikation und Simulation in der Automatisierungstechnik"}, year = {2013}, month = {9}, pages = {42--59}, address = {Anif/Salzburg, Austria}, } - F. Schausberger, A. Steinboeck, and Kugi, Feedback Control of the Contour Shape in Heavy-Plate Hot Rolling, IEEE Transactions on Control Systems Technology, vol. 26, iss. 3, p. 842–856, 2018.

[BibTex] [Download]@Article{Schausberger2018, author = {Schausberger, F. and Steinboeck, A. and Kugi}, title = {Feedback Control of the Contour Shape in Heavy-Plate Hot Rolling}, doi = {10.1109/TCST.2017.2695168}, issn = {1063-6536}, number = {3}, pages = {842--856}, volume = {26}, journal = {IEEE Transactions on Control Systems Technology}, year = {2018}, }

Applications

- Automation of rolling mills

- Continuous production processes

14.06.2017 Modeling, observer design, and control of continuous slab reheating furnaces

Project focus

- Modeling and parameter identification of continuous reheating furnaces

- Observer design for non-measurable system quantities

- Model-based control and optimization of nonlinear dynamical systems

- Nonlinear model predictive control of product temperatures

Description

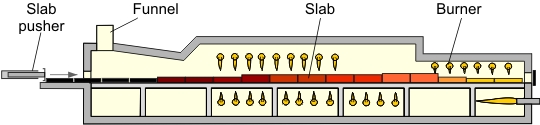

Continuous reheating furnaces are used in the steel industry to reheat slabs (steel blocks weighing up to 40 tons) before they are rolled out in the subsequent rolling process. During the energy- and cost-intensive reheating process, the slabs are lined up and continuously moved through the gas- or oil-fired furnace. The energy consumption of a medium-sized slab reheating furnace is approximately equal to that of a town with 25000 inhabitants. The desired product temperature for the rolling process is between 1050 and 1200 degrees Celsius. It is vital for the product quality that this temperature is accurately reached.

Continuous slab reheating furnace.

The total thermal energy supply of the system is computed by means of a stoichiometric analysis of the combustion process. Convection and especially thermal radiation transfer the heat to the slabs. Based on a geometric discretization of the furnace volume, mass, energy, and radiation balances are considered in the mathematical model. The nonlinear dynamical system has a switched structure because the slabs are discontinuously moved forward.

A hot slab is discharged from the furnace, Copyright: Dillinger Hüttenwerke AG.

The temperature field inside the slabs cannot be measured. It is therefore estimated by state observers (e.g., extended or unscented Kalman filters) using mathematical models that can be evaluated in real-time. A nonlinear model predictive multi-input multi-output controller regulates the local furnace temperatures by means of the fuel supply to the burners. The controller minimizes the energy consumption and ensures that the slabs accurately reach their desired temperatures. Input and state constraints and the diverse product range (different product geometries and desired temperatures) are a challenge for the controller. Another problem is that the sequence of the slabs and their processing times are prescribed by upstream or downstream process steps. Nonlinear model predictive control is used for the high-level multi-input multi-output control task.

The developed control system has been installed on several industrial slab reheating furnaces. Measurements made with an instrumented test slab demonstrate that the slabs are accurately reheated. Compared to conventional furnace control concepts, the system saves a considerable amount of energy, curbs CO2 emissions and thus makes the process more ecologically desirable.

Selected publications

- A. Steinboeck and A. Kugi, Optimized pacing of continuous reheating furnaces, in Proceedings of European Control Conference ECC 2013, Zürich, Switzerland, 2013, p. 4454 – 4459.

[BibTex]@InProceedings{Steinboeck13b, author = {A. Steinboeck and A. Kugi}, title = {{Optimized pacing of continuous reheating furnaces}}, booktitle = {Proceedings of European Control Conference ECC 2013}, year = {2013}, month = {7}, pages = {4454 -- 4459}, url = {http://ieeexplore.ieee.org/xpl/articleDetails.jsp?tp=&arnumber=6669132}, address = {Z\"{u}rich, Switzerland}, } - A. Steinboeck, D. Wild, and A. Kugi, Energy-Efficient Control of Continuous Reheating Furnaces, in Proceedings of 15th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral & Metal Processing, San Diego, USA, 2013, p. 359 – 364.

[BibTex]@InProceedings{Steinbock13, author = {A. Steinboeck and D. Wild and A. Kugi}, title = {{Energy-Efficient Control of Continuous Reheating Furnaces}}, booktitle = {Proceedings of 15th IFAC Symposium on Control, Optimization and Automation in Mining, Mineral \& Metal Processing}, year = {2013}, month = {8}, pages = {359 -- 364}, doi = {10.3182/20130825-4-US-2038.00007}, address = {San Diego, USA}, } - A. Steinboeck, D. Wild, and A. Kugi, Nonlinear model predictive control of a continuous slab reheating furnace, Control Engineering Practice, vol. 21, iss. 4, p. 495–508, 2013.

[BibTex] [Download]@Article{Steinboeck13, Title = {{Nonlinear model predictive control of a continuous slab reheating furnace}}, Author = {A. Steinboeck and D. Wild and A. Kugi}, Journal = {Control Engineering Practice}, Pages = {495--508}, Volume = {21}, Year = {2013}, Number = {4}, Doi = {10.1016/j.conengprac.2012.11.012}, } - A. Steinboeck, D. Wild, and A. Kugi, Optimal Trajectory Planning and Control of a Continuous Slab Reheating Furnace, in Proceedings of the IFAC Workshop on Automation in the Mining, Mineral and Metal Industries, Gifu, Japan, 2012, p. 169 – 174.

[BibTex]@InProceedings{Steinbock12, author = {A. Steinboeck and D. Wild and A. Kugi}, title = {{O}ptimal {T}rajectory {P}lanning and {C}ontrol of a {C}ontinuous {S}lab {R}eheating {F}urnace}, booktitle = {Proceedings of the IFAC Workshop on Automation in the Mining, Mineral and Metal Industries}, year = {2012}, month = {9}, pages = {169 -- 174}, address = {Gifu, Japan}, } - A. Steinboeck, K. Graichen, and A. Kugi, Dynamic Optimization of a Slab Reheating Furnace with consistent Approximation of Control Variables, IEEE Transactions on Control Systems Technology, vol. 19, p. 1444–1456, 2011.

[BibTex] [Download]@Article{Steinboeck11a, Title = {{Dynamic Optimization of a Slab Reheating Furnace with consistent Approximation of Control Variables}}, Author = {A. Steinboeck and K. Graichen and A. Kugi}, Journal = {IEEE Transactions on Control Systems Technology}, Pages = {1444--1456}, Volume = {19}, Year = {2011}, Doi = {10.1109/TCST.2010.2087379}, } - A. Steinboeck, K. Graichen, D. Wild, T. Kiefer, and A. Kugi, Model-based trajectory planning, optimization, and open-loop control of a continuous slab reheating furnace, Journal of Process Control, vol. 21, iss. 2, p. 279–292, 2011.

[BibTex] [Download]@Article{Steinbock11a, Title = {Model-based trajectory planning, optimization, and open-loop control of a continuous slab reheating furnace}, Author = {A. Steinboeck and K. Graichen and D. Wild and T. Kiefer and A. Kugi}, Journal = {Journal of Process Control}, Pages = {279--292}, Volume = {21}, Year = {2011}, Number = {2}, Doi = {10.1016/j.jprocont.2010.08.004}, } - A. Steinboeck, D. Wild, and A. Kugi, Feedback Tracking Control of Continuous Reheating Furnances, in Proceedings of the 18th IFAC World Congress, Milano, Italia, 2011, p. 11744–11749.

[BibTex]@InProceedings{Steinbock11, author = {A. Steinboeck and D. Wild and A. Kugi}, title = {{F}eedback {T}racking {C}ontrol of {C}ontinuous {R}eheating {F}urnances}, booktitle = {Proceedings of the 18th IFAC World Congress}, year = {2011}, month = {8}, pages = {11744--11749}, doi = {10.3182/20110828-6-IT-1002.01639}, address = {Milano, Italia}, } - A. Steinboeck, D. Wild, T. Kiefer, and A. Kugi, A mathematical model of a slab reheating furnace with radiative heat transfer and non-participating gaseous media, International Journal of Heat and Mass Transfer, vol. 53, pp. 5933-5946, 2010.

[BibTex] [Download]@Article{Steinbock10, Title = {A mathematical model of a slab reheating furnace with radiative heat transfer and non-participating gaseous media}, Author = {A. Steinboeck and D. Wild and T. Kiefer and A. Kugi}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {5933-5946}, Volume = {53}, Year = {2010}, Doi = {10.1016/j.ijheatmasstransfer.2010.07.029}, } - D. Wild, T. Meurer, and A. Kugi, Modelling and Experimental Model Validation for a Pusher-type Reheating Furnace, Mathematical and Computer Modelling of Dynamical Systems, vol. 15, iss. 3, p. 209–232, 2009.

[BibTex] [Download]@Article{Wild09, Title = {Modelling and Experimental Model Validation for a Pusher-type Reheating Furnace}, Author = {D. Wild and T. Meurer and A. Kugi}, Journal = {Mathematical and Computer Modelling of Dynamical Systems}, Pages = {209--232}, Volume = {15}, Year = {2009}, Number = {3}, Doi = {10.1080/13873950902927683}, }

Applications

- Automation of rolling mills

- Industrial furnaces

- Continuous production processes

08.06.2017 MMAssist II

Goals and Innovation

The goal of the project partners in MMAssist II is to research and implement modular, reusable assistance systems for employees in production companies. For that, the project partners will work on the exemplary uses cases Maintenance and Service, Arming of Machines and Simultaneous Handling of Multiple Machines, and Montage to analyze the technical and sozio-economic requirements for assistance systems in these areas.

Based on a strongly context-oriented requirements analysis, the partners will implement so-called “Assistance Units”, which are modular components for assistance systems. Assistance Units are defined in a way so that they can be applied to different application contexts.

The partners will implement a software framework with which Assistance Units can be dynamically

configured to act as assistance system for a given application. To configure the Assistance Unit, different input and output modalities as well as modules for context generation are needed, which will also be developed in the project. To measure and evaluate the efficiency and feasibility of the project’s approach, the partners will implement lab-based prototypes of defined Assistance Units and evaluate them in real production environments.

Partners

- PROFACTOR (partner and coordinator)

- Austrian Institute of Technology

- Evolaris next level GmbH

- Fraunhofer Austria Research GmbH

- JOANNEUM RESEARCH Forschungsgesellschaft mbH

- Paris Lodron Universität Salzburg

- Salzburg Research Forschungsgesellschaft m.b.H.

- Technische Universität Wien, Institut für Automatisierungs- und Regelungstechnik

- VIRTUAL VEHICLE Research Center

- ABF Industrielle Automation GmbH

- AVL List GmbH

- Becom Electronics GmbH

- BRP-Powertrain GmbH & Co KG

- DS AUTOMATION GmbH

- Fronius International GmbH

- Geberit Produktions GmbH

- Kapsch BusinessCom AG

- plasmo Industrietechnik GmbH

- RIC (Regionales Innovations Centrum) GmbH

- Siemens Transformers Austria GmbH & Co KG

- Tablet Solutions

- Tieto Austria GmbH

- TÜV AUSTRIA HOLDING AG

- Wacker Neuson Beteiligungs GmbH

- XiTrust Secure Technologies GmbH

Funding

FFG – Austrian Research Promotion Agency

08.06.2017 Modeling and Control of a Cooling System with compact plate heat exchangers

Project focus

- Modeling of the heat transfer of a compact plate heat exchanger

- Physical based model reduction

- Nonlinear control design based on power considerations

Description

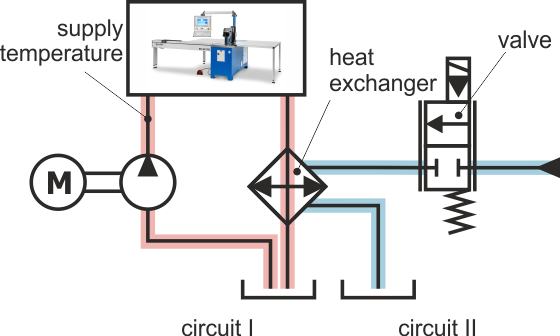

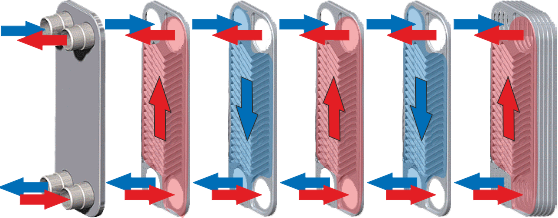

In the operation of machine tools it is necessary to compensate the introduced heat in order to reduce the deformation of the machine and thus minimize the manufacturing tolerances. Usually, the manufacturers of the machine tools demand a temperature tracking control of the supply fluid with the ambient temperature. Therefore, often fluid-fluid cooling systems are used, which consist of two fluid circuits as shown in Fig. 1. The primary circuit (I) is connected to the machine tool and the secondary circuit (II) to a coolant supply. Compact plate heat exchangers are often used as thermal coupling of both circuits. Their advantages are a small overall size, high overall heat transfer coefficients and low production costs.

Schematics of a fluid-fluid cooling system.

The control problem is concerned with the tracking control of the supply temperature of the machine tool by changing the fluid velocity of the secondary circuit with a proportional valve. The temperature of the coolant supply cannot be changed and may vary within a small but unknown range. Neglecting the heat transfer with the environment, the control problem reduces to a tracking control of the outlet temperature of circuit I of the heat exchanger.

The mathematical model of a heat exchanger is a distributed-parameter system because of the convective heat transfer. In addition, from the thermal boundary layers of the fluids, the overall heat transfer coefficient shows a strong nonlinear dependency from the fluid velocities. In this context, the precise identification of the functional relation between the overall heat transfer coefficient and the fluid velocities turns out to be a laborious task.

Compact plate heat exchanger in countercurrent flow arrangement.

Due to the specific design and the typical operating conditions, the mathematical model of the plate heat exchanger can be reduced to only two ordinary nonlinear differential equations. Based on the total power balance a nonlinear control law, which is independent of the overall heat transfer coefficient can be designed.

The proposed control strategies have already been successfully implemented on an industrial control system.

- A. Michel, Modellbasierte Regelung von industriellen Wärmeübertragern, A. Kugi and K. Schlacher, Eds., Aachen: Shaker Verlag, 2015, vol. 24.

[BibTex]@Book{Michel15, Title = {Modellbasierte Regelung von industriellen W\"arme\"ubertragern}, Author = {Michel, Alexander}, Editor = {A. Kugi and K. Schlacher}, Publisher = {Shaker Verlag}, Year = {2015}, Address = {Aachen}, Series = {Modellierung und Regelung komplexer dynamischer Systeme}, Volume = {24}, ISBN = {978-3-8440-3659-6}, Organization = {Institute f{\"u}r Automatisierungs- und Regelungstechnik (TU Wien) und Regelungstechnik und Prozessautomatisierung (JKU Linz)}, } - A. Michel and A. Kugi, Model based control of compact heat exchangers independent of the heat transfer behavior, Journal of Process Control, vol. 24, p. 286–298, 2014.

[BibTex] [Download]@Article{Michel14, Title = {Model based control of compact heat exchangers independent of the heat transfer behavior}, Author = {Michel, Alexander and Kugi, Andreas}, Journal = {Journal of Process Control}, Pages = {286--298}, Volume = {24}, Year = {2014}, Doi = {10.1016/j.jprocont.2014.02.003}, } - A. Michel and A. Kugi, Accurate low-order dynamic model of a compact plate heat exchanger, International Journal of Heat and Mass Transfer, vol. 61, iss. 33, pp. 323-331, 2013.

[BibTex] [Download]@Article{Michel13, Title = {Accurate low-order dynamic model of a compact plate heat exchanger}, Author = {Michel, A. and Kugi, A.}, Journal = {International Journal of Heat and Mass Transfer}, Pages = {323-331}, Volume = {61}, Year = {2013}, Number = {33}, Doi = {10.1016/j.ijheatmasstransfer.2013.01.072}, } - A. Michel, W. Kemmetmüller, and A. Kugi, Modellierung und Regelung eines Plattenwämetauschers, in Tagungsband GMA-Fachausschuss 1.40 “Theoretische Verfahren der Regelungstechnik”, Anif/Salzburg, Austria, 2010, p. 81–99.

[BibTex]@InProceedings{Michel10, author = {A. Michel and W. Kemmetm{\"u}ller and A. Kugi}, title = {{M}odellierung und {R}egelung eines {P}lattenw{\"a}metauschers}, booktitle = {Tagungsband GMA-Fachausschuss 1.40 "Theoretische Verfahren der Regelungstechnik"}, year = {2010}, month = {9}, pages = {81--99}, address = {Anif/Salzburg, Austria}, }

Applications

- Control strategies for heat exchangers

- Process automation

- Automation of machine tools